A collaborative control method for the production of cigarette makers and wire feeders based on work orders

A collaborative control and cigarette making machine technology, applied in the fields of tobacco, cigarette manufacturing, application, etc., can solve problems such as manual processing in the planning management system, quality accidents, and misbranded cigarette shreds, so as to improve efficiency and execution accuracy, and prevent Misbranding accidents and the effect of preventing misbranding of shredded tobacco

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

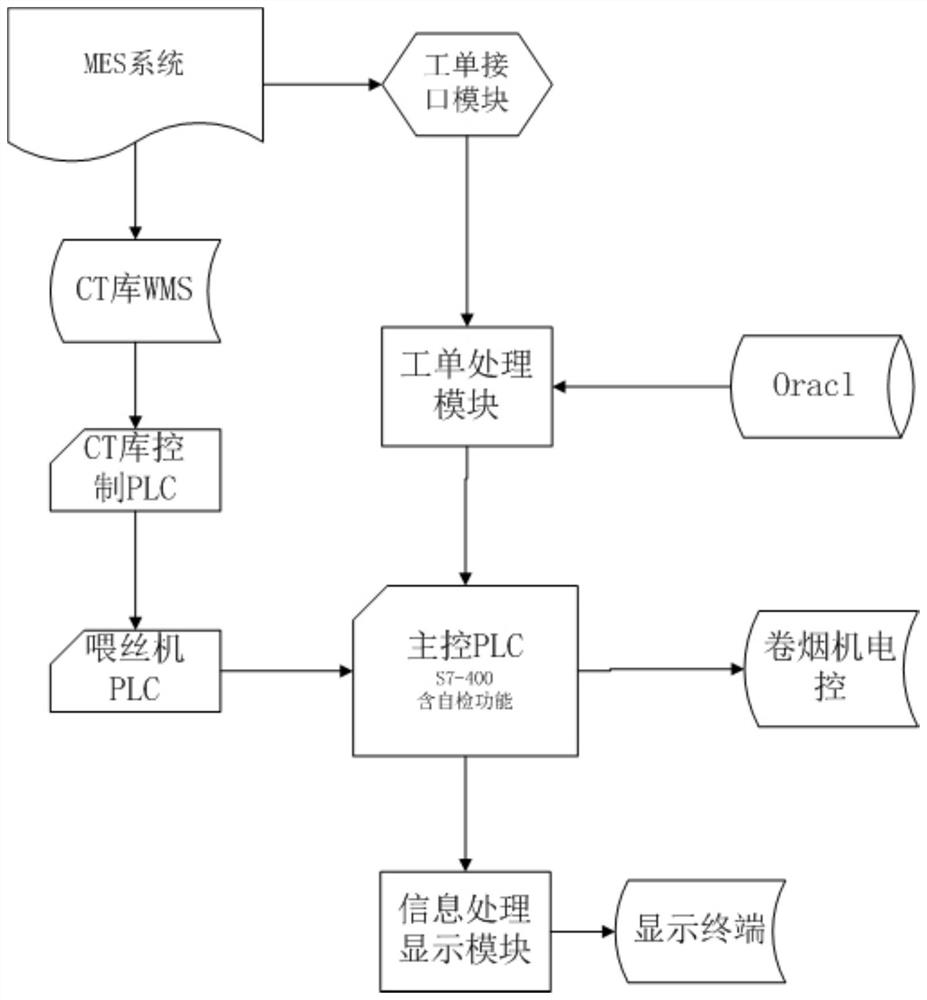

Method used

Image

Examples

Embodiment 1

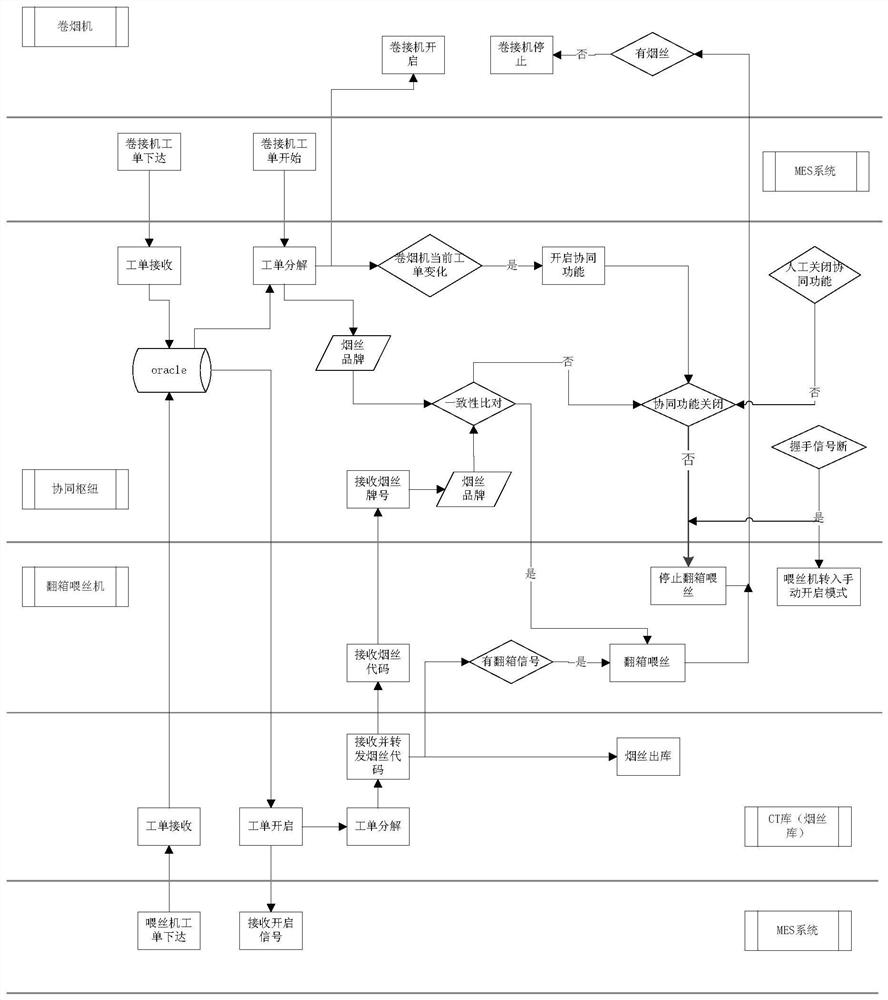

[0046] (The following only describes one production work order of cigarette machine E08 and wire feeding machine J04 on a certain day as an example. In actuality, there may be multiple production work orders in one day. In the example, E08 and J04 have a one-to-one correspondence, and one J04 actually feeds wire The machine can correspond to multiple cigarette making machines):

[0047] 1) The MES system schedules the production through the built-in production scheduling module, and generates the daily production work orders of the cigarette making machine, case sealing machine and wire feeding machine for the next month (Including work order number, cigarette brand number, planned output, BOM version, work order status, etc.) , taking the production work orders of No. E08 cigarette machine and J04 wire feeding machine on the 21st of a certain month as an example;

[0048] 2) The built-in work order issuing module of the MES system sends the newly generated E08 cigarette mach...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com