A cross-flow stirring paddle

A stirring paddle and flow-through technology, which is applied in the field of stirring paddles, can solve problems such as low stirring efficiency, and achieve the effects of high stirring efficiency, improving mixing effect and shortening mixing time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

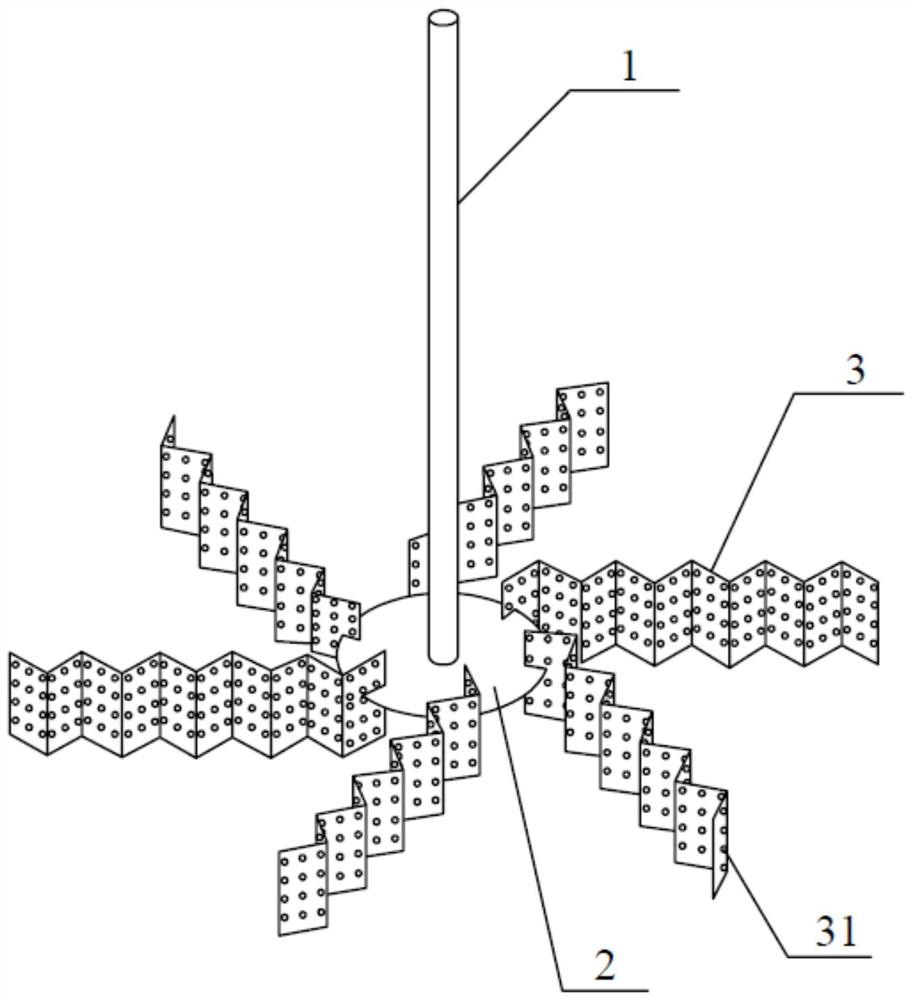

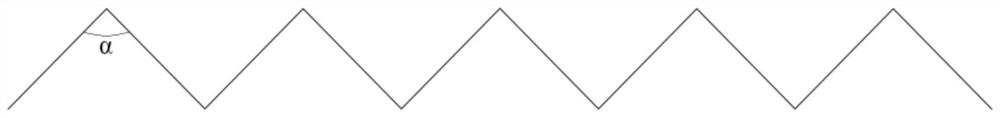

[0033] The stirred tank (not shown in the figure) reactor has a diameter of 240 mm and a height of 300 mm. Four baffles are installed away from the wall, and the baffles are 300 mm high and 20 mm wide. The top view of the through-flow paddle blade 3 is a broken line (ie figure 2 ), the angle α between two adjacent broken lines is 45°, the diameter of the through-flow hole 31 is 5 mm, and the center-to-center distance between two adjacent through-flow holes 31 is 10 mm. The paddle diameter of the paddle 3 is 80 mm, the paddle height is 24 mm, the number of blades of the paddle 3 is 6, and the height of the paddle 3 from the bottom is 80 mm.

[0034] Figure 5 It is a structural schematic diagram of the through-flow stirring paddle in the prior art, and its difference from the through-flow stirring paddle provided by the present invention is that the shape of the paddle 3 in the present invention is a wave-shaped structure, while the through-flow stirring paddle in the prior a...

Embodiment 2

[0040] Other conditions are the same as in Example 1, except that the diameter of the through-flow hole 31 is 6mm. The results of the comparative experiment are shown in Table 2.

[0041] Table 2 Performance comparison between the existing through-flow propeller and the high-efficiency through-flow propeller of the present invention

[0042]

[0043] It can be seen from the experimental results in Table 2 that at the same stirring speed, the mixing time of the through-flow stirring blade of the present invention is shortened by 12.75% compared with the existing through-flow stirring blade.

Embodiment 3

[0045] Other conditions are the same as in Example 1, except that the shape of the through-flow stirring paddle 3 is arc-shaped, and the results of the comparative experiment are shown in Table 3.

[0046] Table 3 Performance comparison between the existing through-flow paddle and the high-efficiency through-flow paddle of the present invention

[0047]

[0048] It can be seen from the experimental results in Table 3 that at the same stirring speed, the mixing time of the through-flow stirring blade of the present invention is shortened by 11.82% compared with the existing through-flow stirring blade.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com