A built-in screw-rod pulsating cyclone

The technology of a cyclone and a screw rod is applied in the field of two-phase separation treatment devices, which can solve the problems of difficulty in meeting water injection requirements, low oil removal efficiency in the sedimentation section, and increase in the load of the filter section, etc., so as to eliminate the air column and its adverse effects, Improved processing efficiency, reduced radial range effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with accompanying drawing:

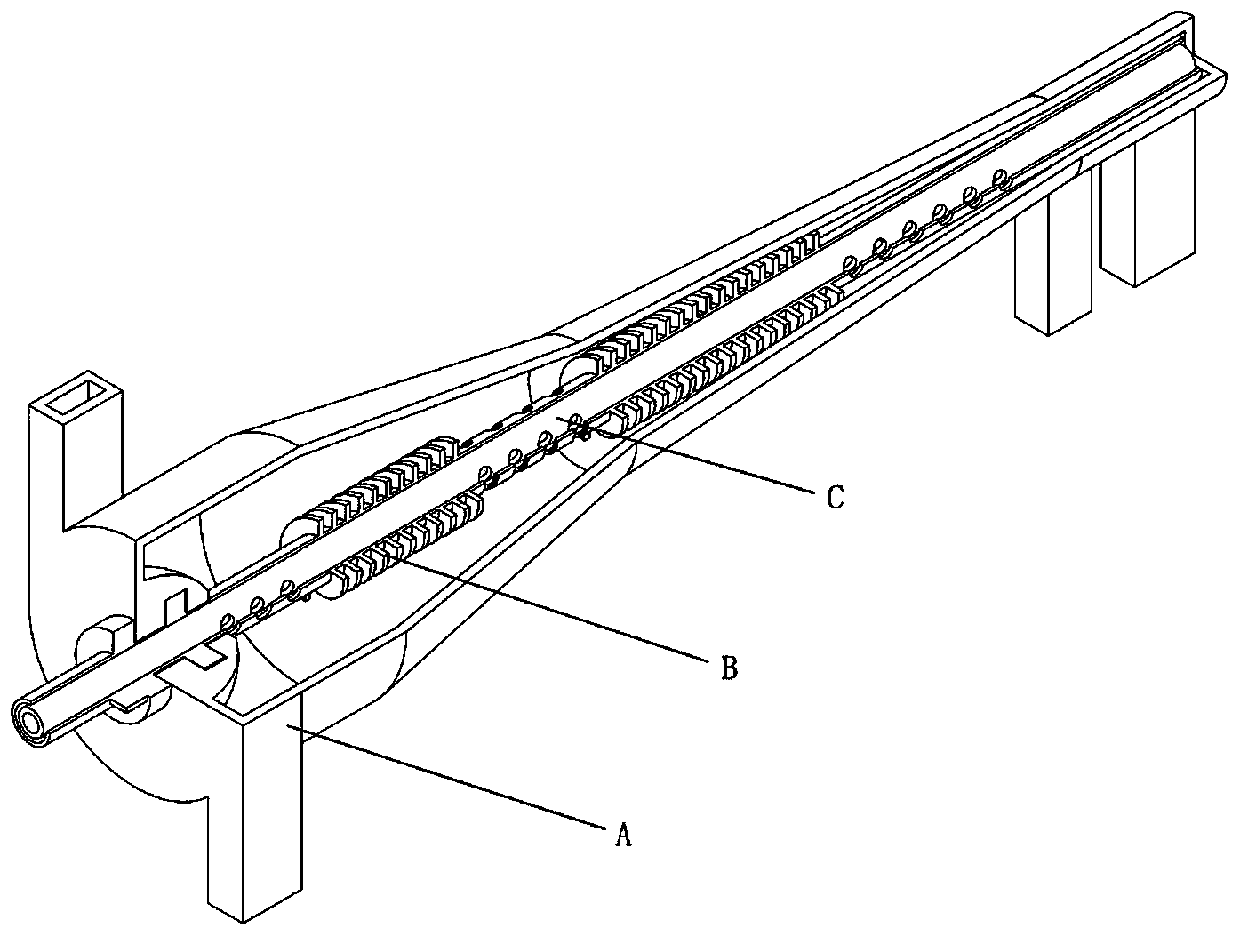

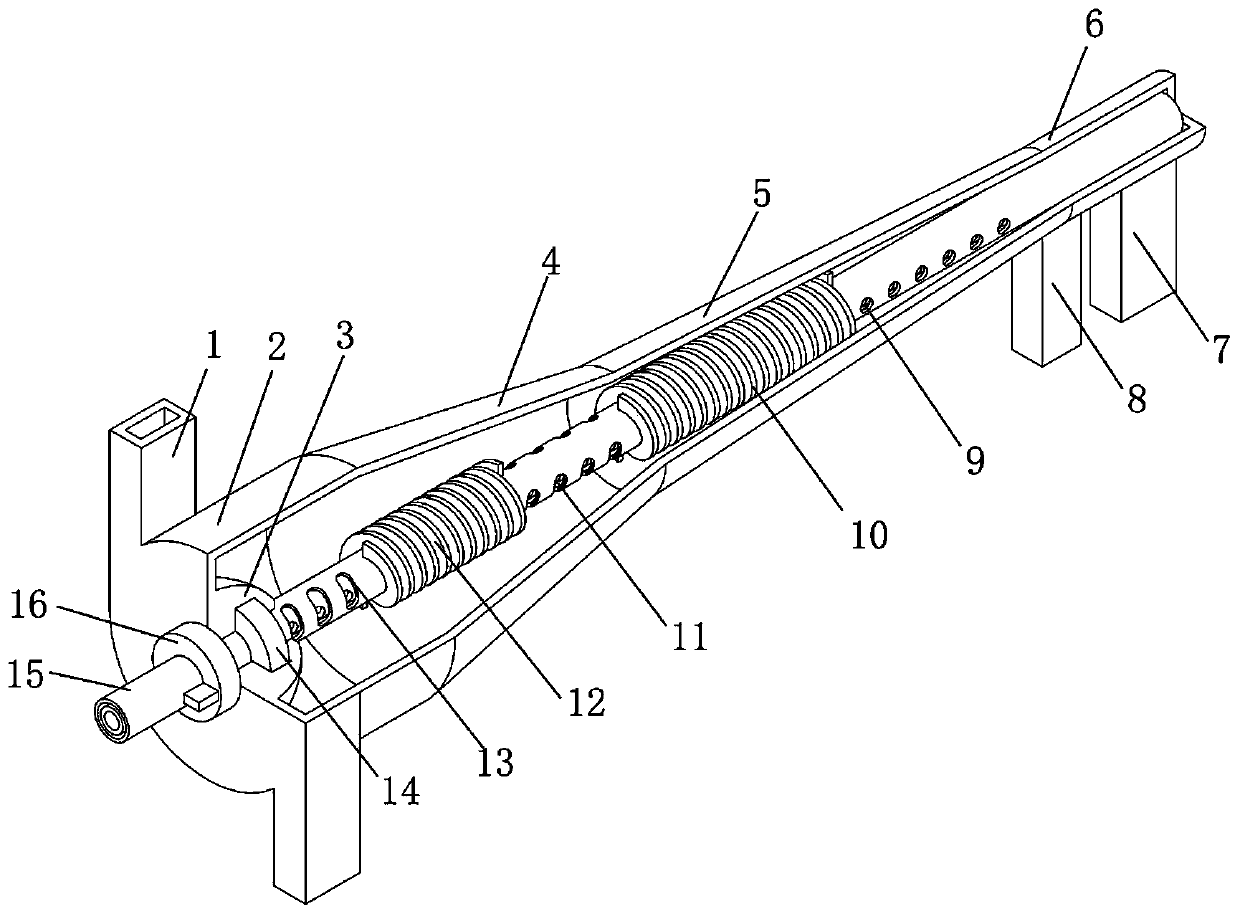

[0034] Depend on Figure 1 to Figure 11 As shown, this kind of built-in screw rod type pulsating cyclone includes a cyclone outer cylinder, and the cyclone outer cylinder has a double tangential inlet 1, a swirl chamber 2, a large cone section 4, a small cone section 5, The conventional structures of the liner section 6 and the tangential underflow opening 7 are unique in that:

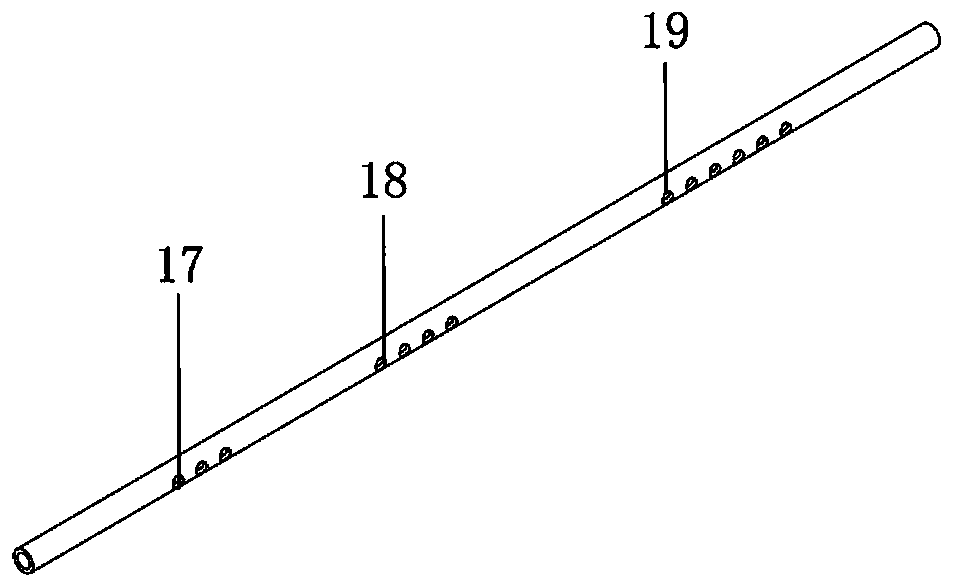

[0035]A discontinuous screw rod is built in the outer cylinder of the cyclone. The interior of the discontinuous screw rod is hollow. From top to bottom, there are overflow section 15, upper opening section 13, upper helical section 12, and middle opening. The hole section 11, the lower helical section 10 and the lower opening section 9, the opening section is smooth without spiral. Among them, between the overflow section 15 and the upper opening section 13, a first positioning round table 16 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com