Waterproof equipment pre-impregnation machine

A prepreg and equipment technology, which is applied in the direction of pretreatment surface, coating, device for coating liquid on the surface, etc. It can solve the problems of poor extrusion effect, and achieve compact structure, long extrusion time and less space occupation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

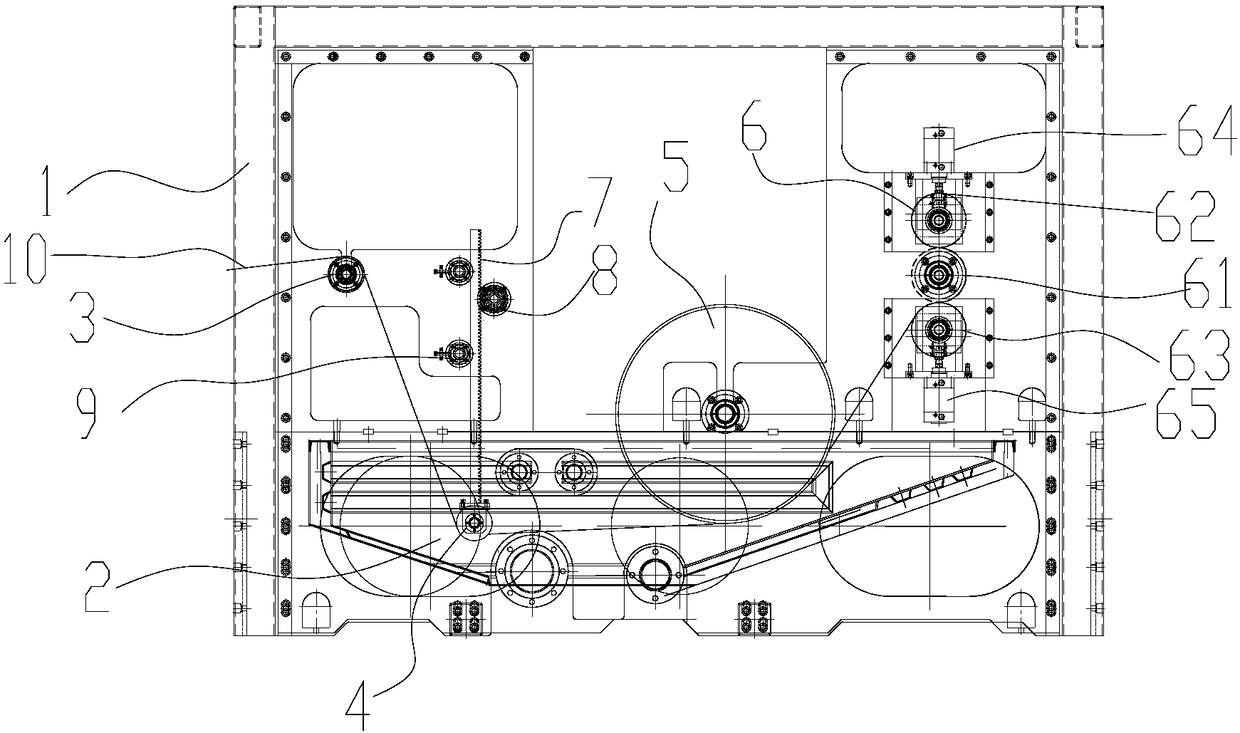

[0013] Such as figure 1 , a prepreg machine for waterproof equipment, including a frame 1, a prepreg oil pool 2 is provided at the bottom of the frame 1, and guide heating rollers 3 are arranged on the frame 1 from left to right, for adjusting the tire cloth to enter the prepreg The up and down adjustment roller 4 of the length of the oil pool 2, the tire cloth driving roller 5 and the prepreg extrusion molding mechanism 6, the prepreg extrusion molding mechanism 6 includes a fixed roller 61 fixedly arranged on the frame 1, and the two ends of the fixed roller 61 are respectively A first squeeze roller 62 and a second squeeze roller 63 are provided, the first squeeze roller 62 is connected with a first driving mechanism that presses the first squeeze roller 62 to the fixed roller 61, and the second squeeze roller 63 is A second driving mechanism for pressing the second extrusion roller 63 to the fixed roller 61 is connected, and a third driving mechanism for driving the vertic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com