Ultrasonic cleaning line for axial diode

An axial diode and ultrasonic technology, applied in cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc., can solve the problems of heavy workload, low cleaning efficiency, high production cost, etc., and achieve improved efficiency and cleaning Fast speed and good cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing:

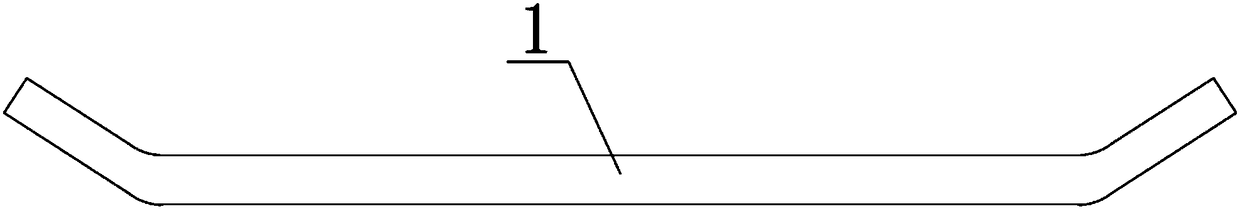

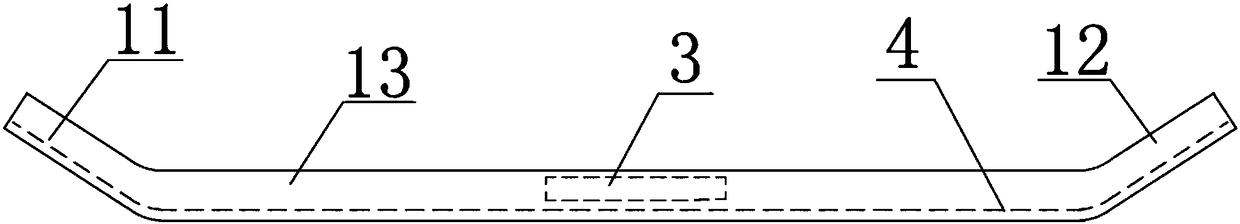

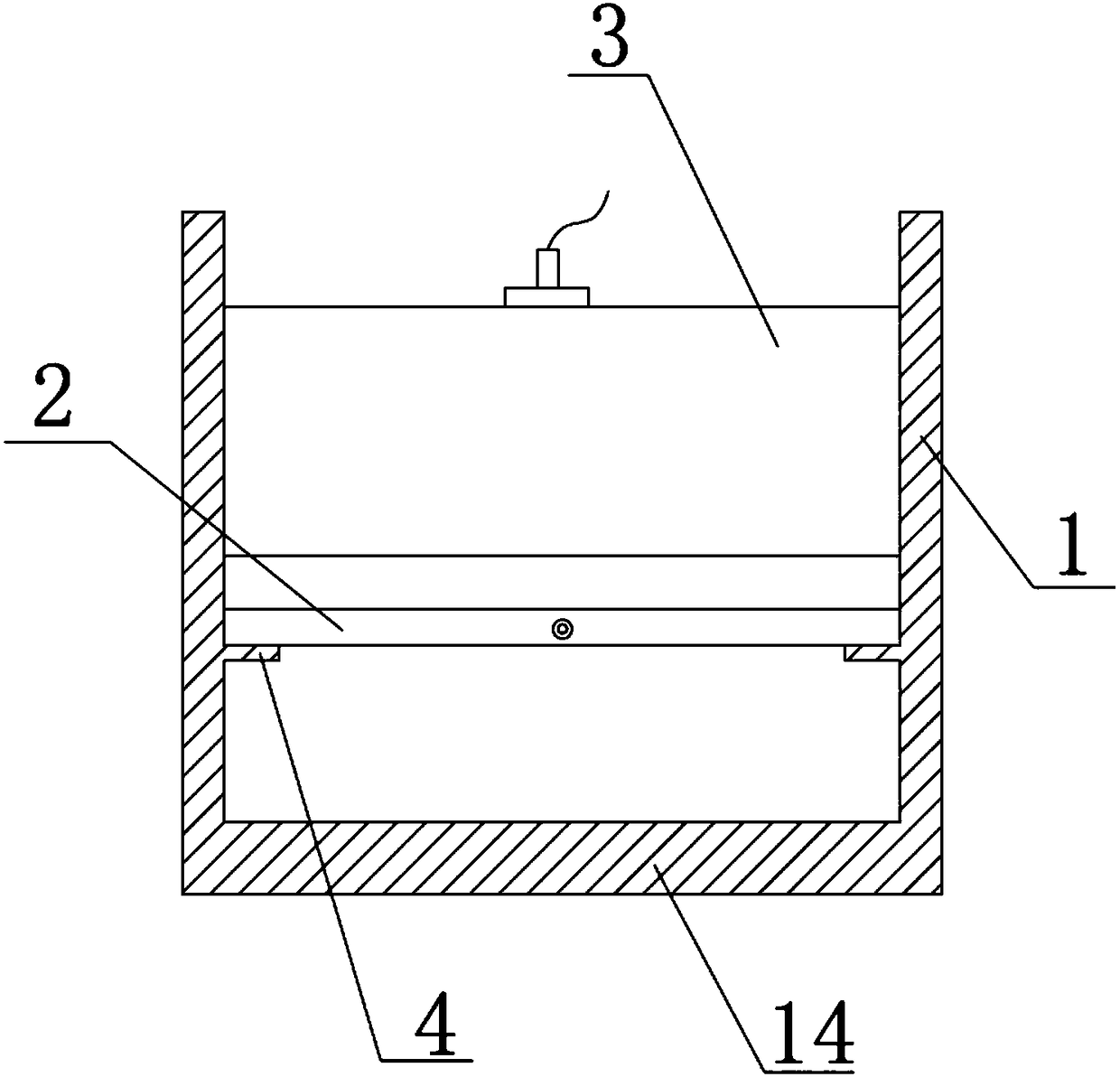

[0024] The invention provides an axial diode ultrasonic cleaning line, such as figure 1 , figure 2 and image 3 As shown, it includes a cleaning tank 1, a sliding plate 2 and an ultrasonic generator 3; the sliding plate 2 is provided with a through hole for placing a diode, and the through hole runs through the upper top surface and the lower bottom surface of the sliding plate 2, and the cleaning The cross section of the tank 1 is U-shaped, the cleaning tank 1 is provided with a slide rail 4 along the length direction of the cleaning tank 1, the sliding plate 2 is placed on the slide rail 4, and the sliding plate 2 slides along the slide rail 4 , during the sliding process of the sliding plate 2 , the sliding plate 2 is parallel to the bottom plate 14 of the cleaning tank 1 . The sonotrode 3 is fixedly installed in the cleaning tank 1 and above the slide rail 4, the so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com