Device and method for expanding diameter of shape memory alloy pipe joint

A memory alloy and pipe joint technology, applied in the field of pipe joint diameter expansion equipment, can solve the problems of pipe joint connection strength, sealing performance and service life reduction, pipe joint damage to the inner ridge of the pipe joint, and difficulty in ensuring the forming quality, etc., to achieve expansion The diameter speed and diameter expansion are easy to control, the connection strength and sealing are guaranteed, and the structure is compact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

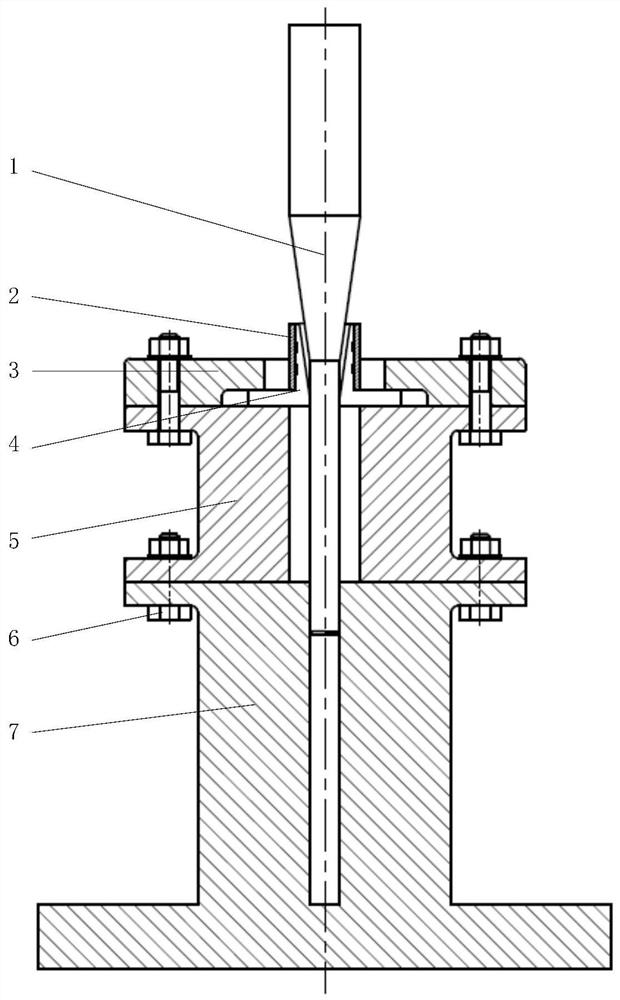

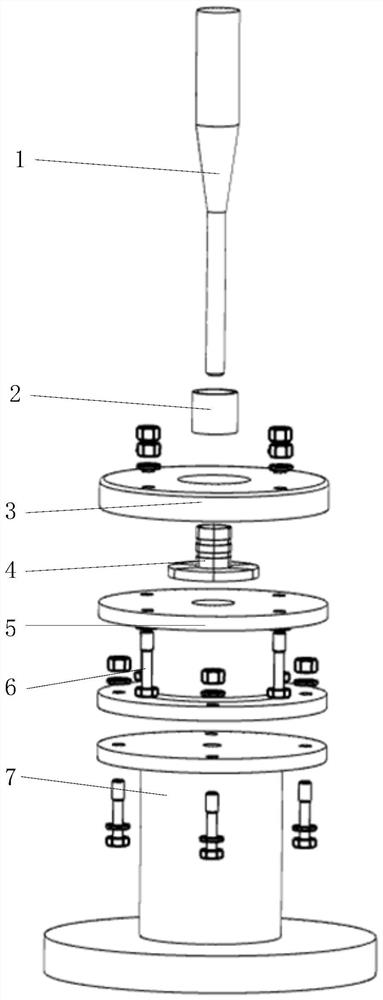

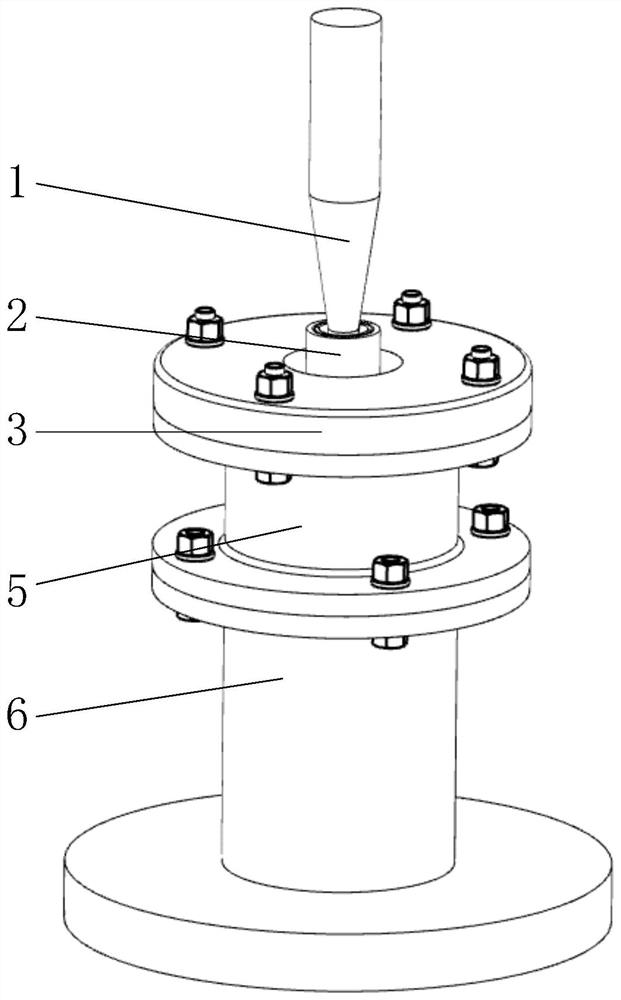

[0032] Such as Figure 1-3 As shown, a shape memory alloy pipe joint diameter expansion device includes a diameter expansion rod 1, a diameter expansion valve mold 4, a material retaining plate 3, a pad 5, a base 7, and a bolt 6, and the pad 5 passes through four bolts 6 is connected to the top surface of the base 7, the diameter-expanding rod 1 is inserted into the center positioning hole of the base 7 and forms a sliding fit with the center positioning hole, and the diameter-expanding valve mold 4 surrounds the The diameter-expanding rod 1 is placed on the top surface of the spacer 5, the material baffle plate 3 is connected to the top surface of the spacer 5 by four bolts 6, and the step surface of the expansion petal mold 4 The top is located under the stepped surface of the central hole of the baffle plate 3, and the diameter-expanding valve mold 4 forms a sliding fit with the baffle plate 3 and the pad 5; 2 is set on the top cylinder of the expanded diameter valve mold ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com