A Rigid Expanding Device for Shape Memory Alloy Pipe Joints with Internal Ribs

A memory alloy and pipe joint technology, which is applied in metal processing equipment, forming tools, manufacturing tools, etc., can solve problems such as uneven diameter expansion deformation, difficult to accurately control the expansion amount, and complicated diameter expansion devices, and achieve diameter expansion and Easy disassembly operation, precise and controllable diameter expansion, and simple expansion device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific implementation process of the present invention will be further described below with reference to the accompanying drawings.

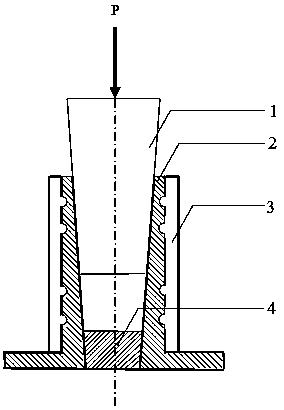

[0015] combine figure 1 As shown, a rigid diameter expansion device of a shape memory alloy pipe joint with internal ribs involved in the present invention includes a conical indenter 1 , a radial diameter expansion die 2 , a shape memory alloy pipe joint 3 and a limit block 4 .

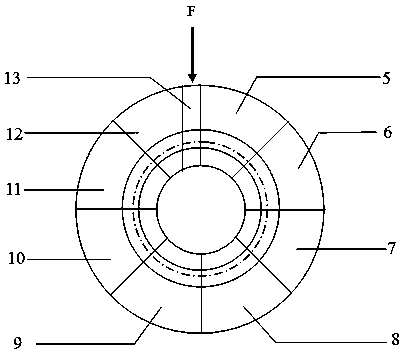

[0016] combine figure 2 As shown, the radial expansion die 2 includes 7 1 / 8 modules 5 to 11 arranged along the circumferential direction, a trapezoidal module 12 and a parallel module 13, wherein the parallel module 13 is to ensure the radial expansion die 2 It is the key not to damage the inner rib of the pipe joint during installation and disassembly of each module.

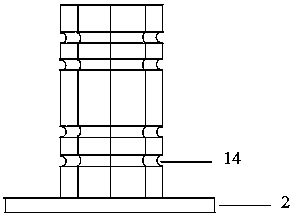

[0017] combine image 3 As shown, in order to protect the inner rib 15 of the shape memory alloy pipe joint 3 from damage during the expansion and deformation process, an annular groove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com