Height-adjustable automatic plug-in new energy vehicle charging pile

A new energy vehicle, automatic plug-in technology, applied in electric vehicle charging technology, electric vehicles, charging stations, etc., can solve problems such as human body electric shock, and achieve the effect of ensuring stability and stable lifting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

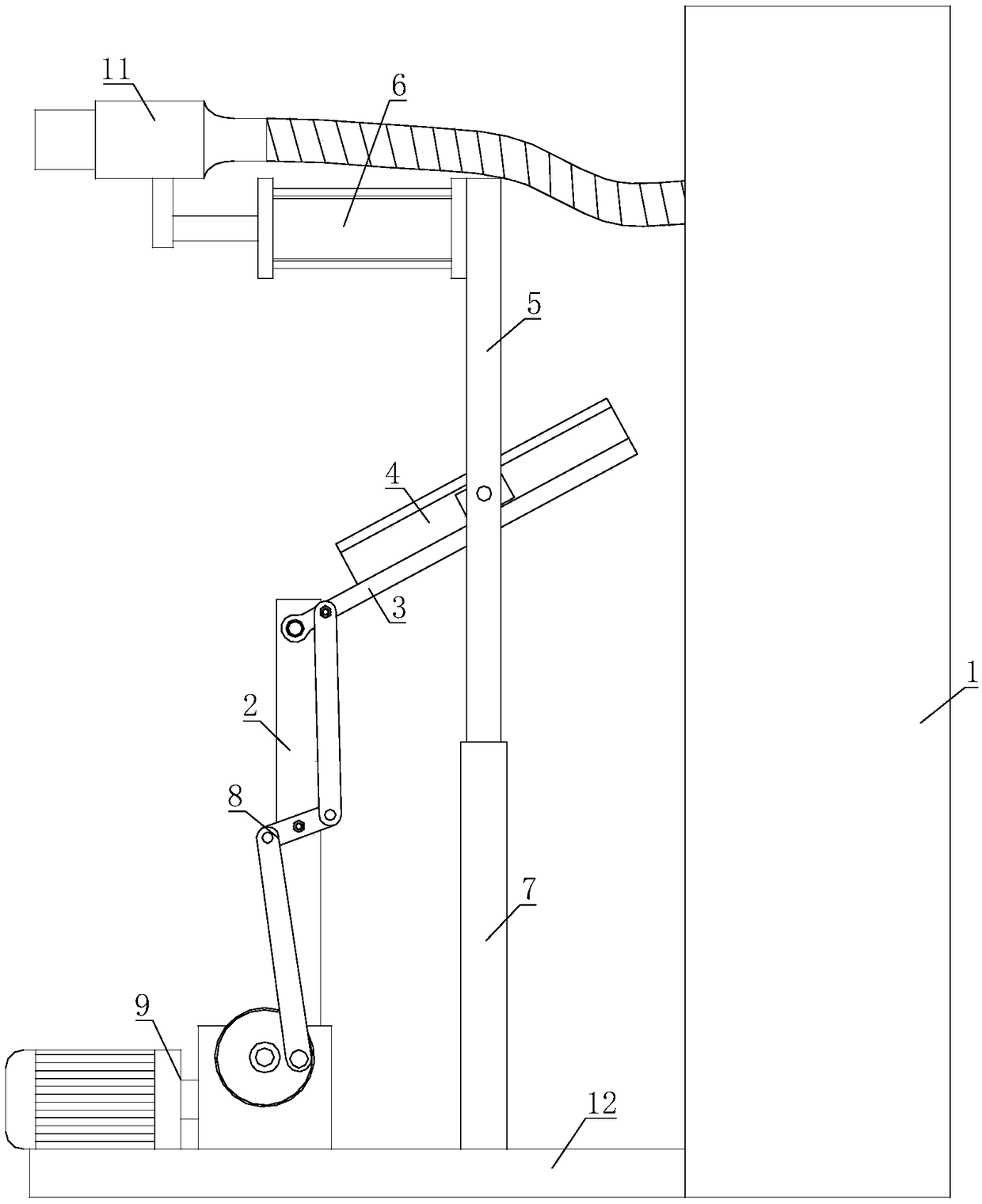

[0023] The height-adjustable automatic plug-in new energy vehicle charging pile includes a charging pile main body 1, and a charging plug 11 is connected to the charging pile main body 1; a mounting plate 12 is connected to the charging pile main body 1, and the mounting plate 12 is installed Mounting rod 2, the top of the mounting rod 2 is hinged with a rotating rod 3, the other end of the rotating rod 3 is fixed with a sliding mechanism 4, the sliding mechanism 4 is hinged with a lifting rod 5, the upper end of the lifting rod 5 is connected with a cylinder 6 The piston rod is fixed to the charging plug 11; a sleeve 7 is fixed on the mounting plate 12, and the other end of the lifting rod 5 is sleeved in the sleeve 7; the mounting rod 2 is hinged with a transmission mechanism 8, one end of the transmission mechanism 8 and a rotating rod The middle part of 3 is hinged, and the other end of the transmission mechanism 8 is hinged with a driving mechanism 9 for driving the transmi...

Embodiment 2

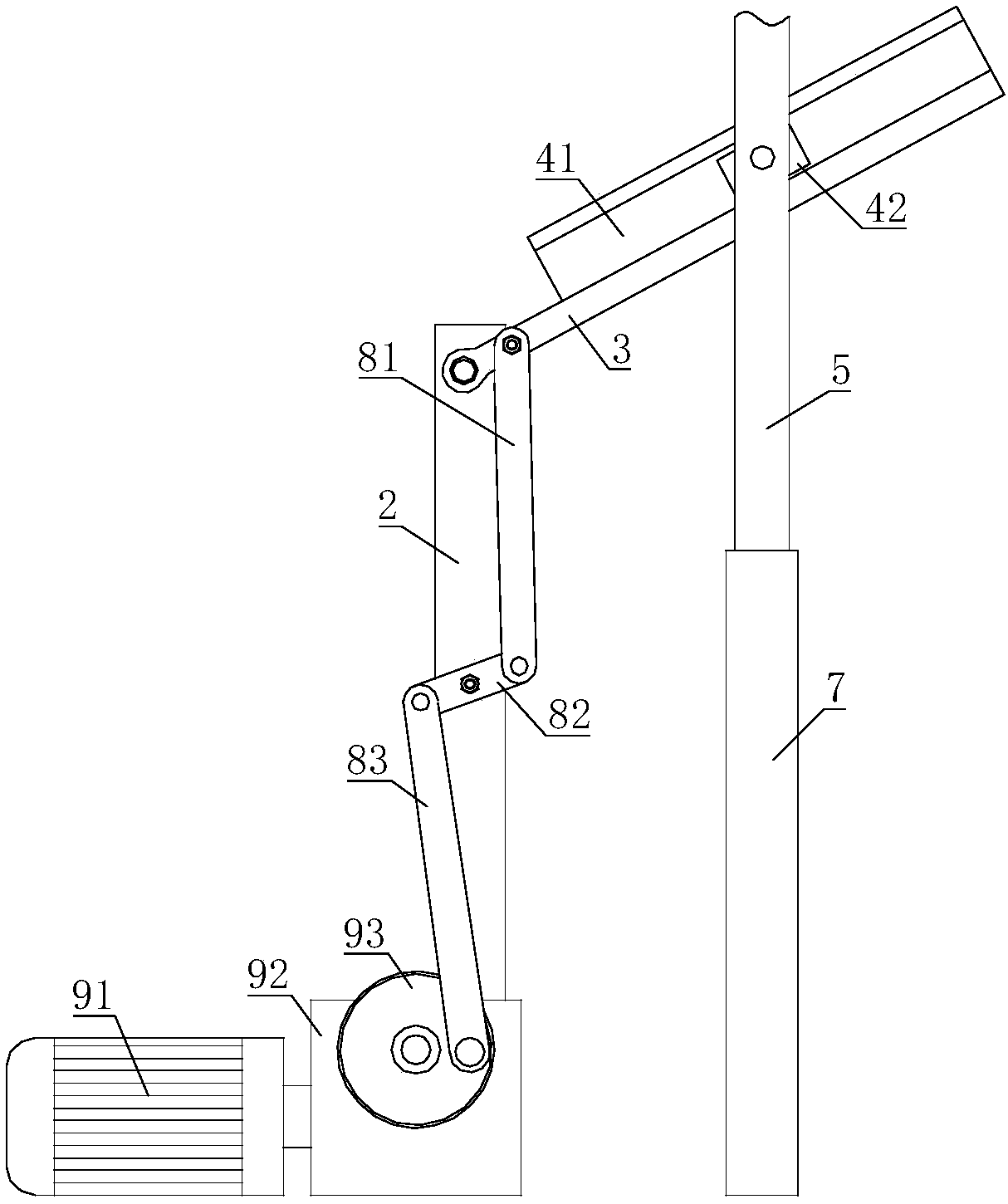

[0026] On the basis of the first embodiment, the transmission mechanism 8 includes a first link 81, one end of the first link 81 is hinged with the middle of the rotating rod 3, and the other end of the first link 81 is hinged with a rocker 82, The other end of the rod 82 is hinged with a second link 83, the middle of the rocker 82 is hinged on the mounting rod 2, and the other end of the second link 83 is hinged with the driving mechanism 9.

[0027] When the driving mechanism 9 pulls the second link 83 to move, the rocker 82 rotates accordingly, and the first link 81 moves under the drive of the rocker 82, so that the first link 81 can push the rotating rod 3 to tilt. According to needs, the driving mechanism 9 can change the transmission mechanism 8 to a certain shape by controlling the action time, so that the lifting rod 5, the air cylinder 6, and the charging plug 11 can be lifted accurately.

Embodiment 3

[0029] On the basis of the first or second embodiment, the driving mechanism 9 includes a motor 91, the output shaft of the motor 91 is connected with a reducer 92, the motor 91 and the reducer 92 are both mounted on the mounting plate 12, and the speed reducer 92 A turntable 93 is connected to the output shaft, and the transmission mechanism 8 is hinged with the edge of the turntable 93.

[0030] When the motor 91 drives the speed reducer 92 to move, the speed reducer 92 drives the turntable 93 to rotate, so that the transmission mechanism 8 drives the rotating rod 3 and the sliding mechanism 4 to tilt accordingly. When the motor 91 is stopped, the position of the lifting rod 5 cannot be changed by itself, which avoids the problem of the charging plug 11 falling down by itself.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com