Device and method for signal cable conductor drawing-out and plugging-in in lighting inspection

A signal cable and lighting inspection technology, which is applied in nonlinear optics, instruments, optics, etc., can solve the problems of limited precision, connector damage, long time required to insert signal cables, etc., to reduce production time and reduce damage , Reduce the effect of electrostatic discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

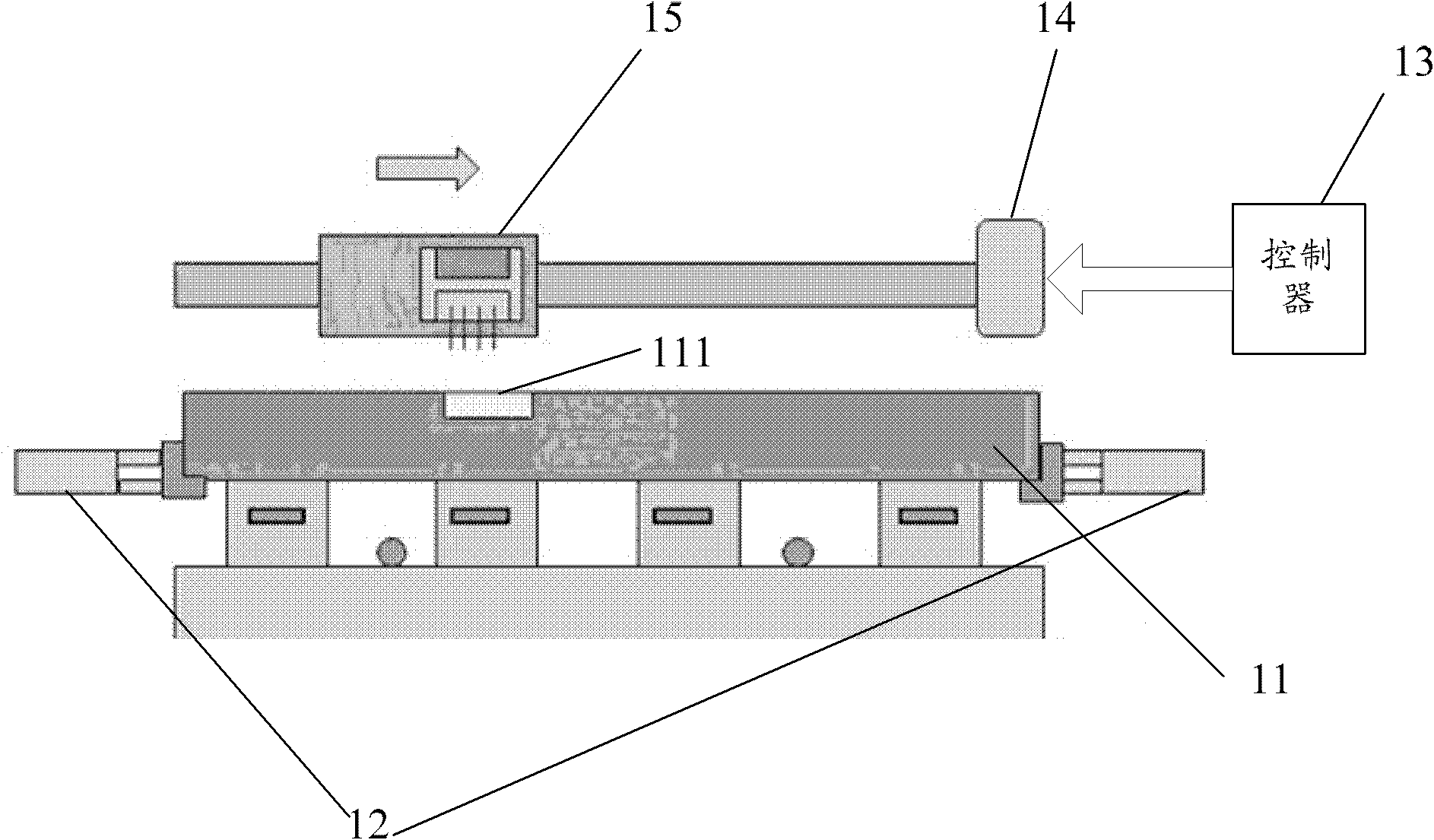

[0053] 本发明的点灯检查中插拔信号电缆线的装置,如 figure 1 所示,该装置包括:PCB 11、固定装置12、控制器13、驱动装置14、以及信号传输模块15;其中,

[0054] PCB 11,包括连接器111;

[0055] 固定装置12,用于在需要进行点灯检查时,固定PCB 11;

[0056] 控制器13,用于控制驱动装置14进行驱动;

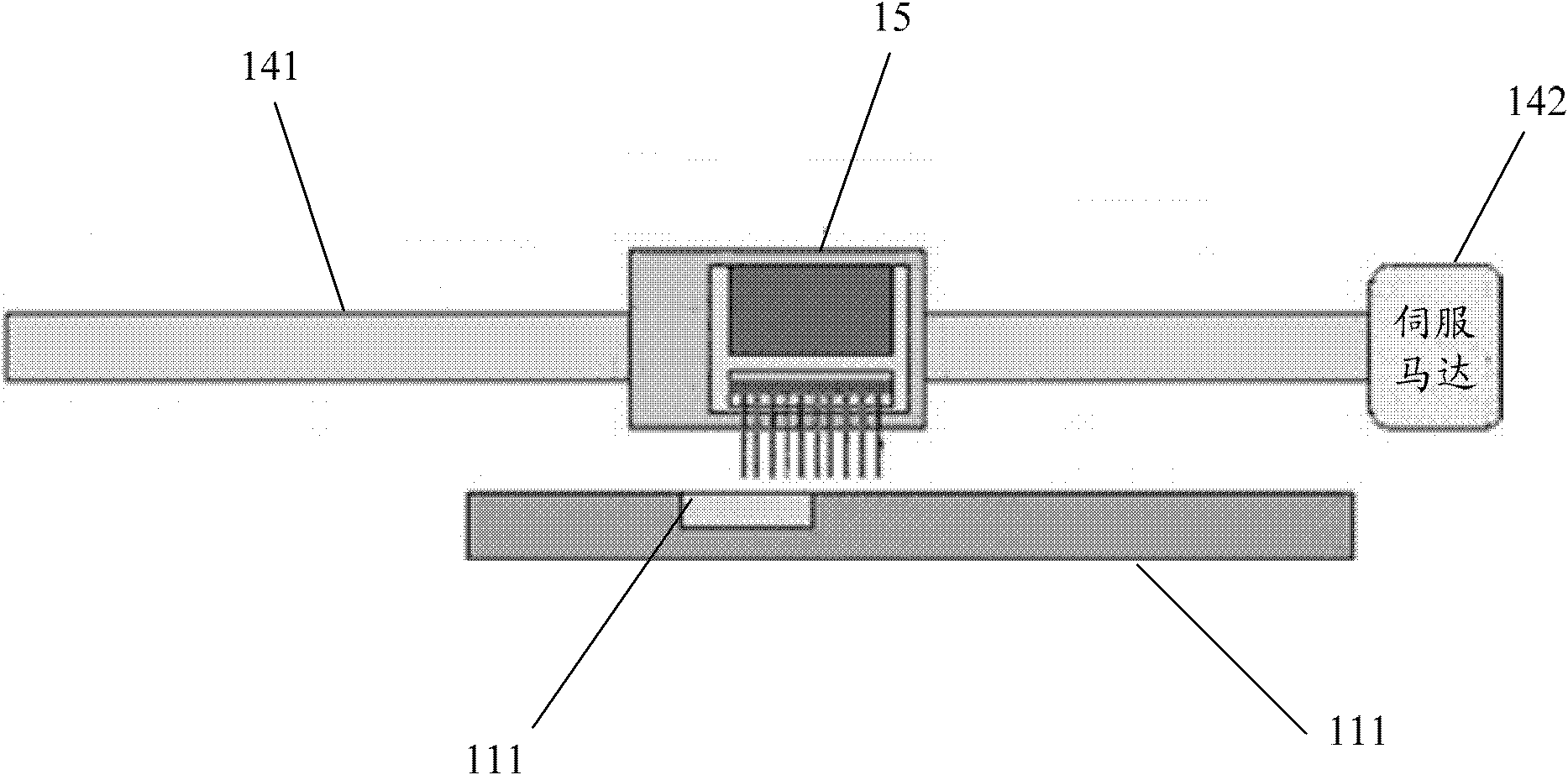

[0057] 驱动装置14,用于在控制器13的控制下,驱动信号传输模块15移至连接器111位置,与连接器111连接;并在点灯检查完成后,在控制器13的控制下,驱动信号传输模块15断开与连接器111的连接;

[0058]One end of the signal transmission module 15 is connected to the signal cable connected to the inspection machine body, and the other end is in contact with the connector 111 for connecting the signal transmission line.

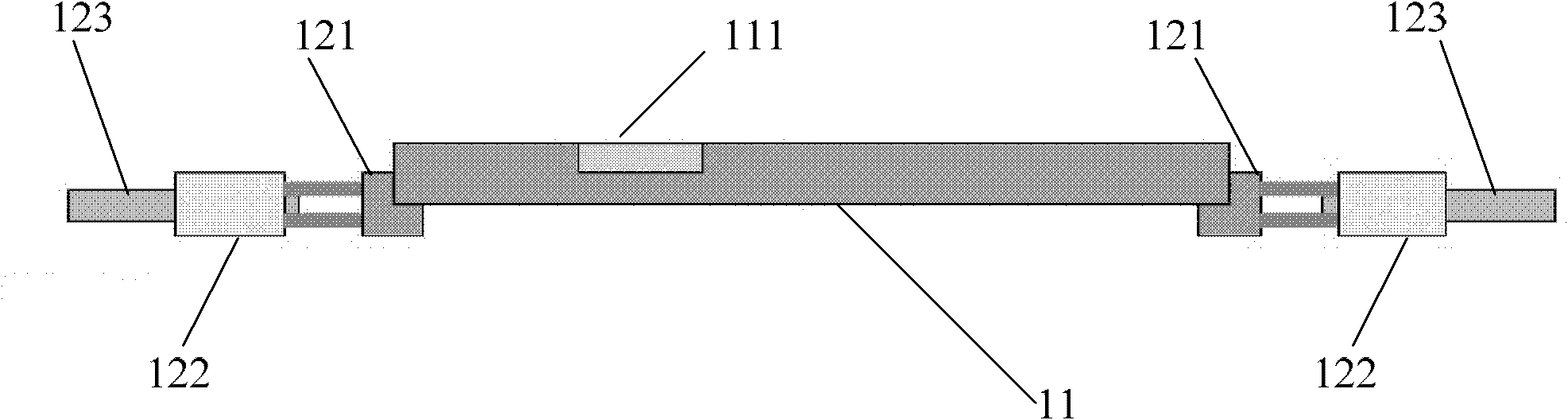

[0059] Wherein, the fixture 12, such as figure 2 As shown, it can further include a fastening part 121, a cylinder 122, and a fixed slide rail 123; wherein,

[0060] The fastening part 121 is used to fix the PCB 11 under the drive of the cylinder 122;

[0061] The cylinder 122 is installed on the fixed slide rail 123...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com