Supporting structure using Larsen steel sheet piles and construction method thereof

A Larsen steel sheet pile and support structure technology, applied in the direction of foundation structure engineering, sheet pile walls, excavation, etc., can solve problems such as safety and hidden dangers that are prone to occur, and achieve the effect of improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

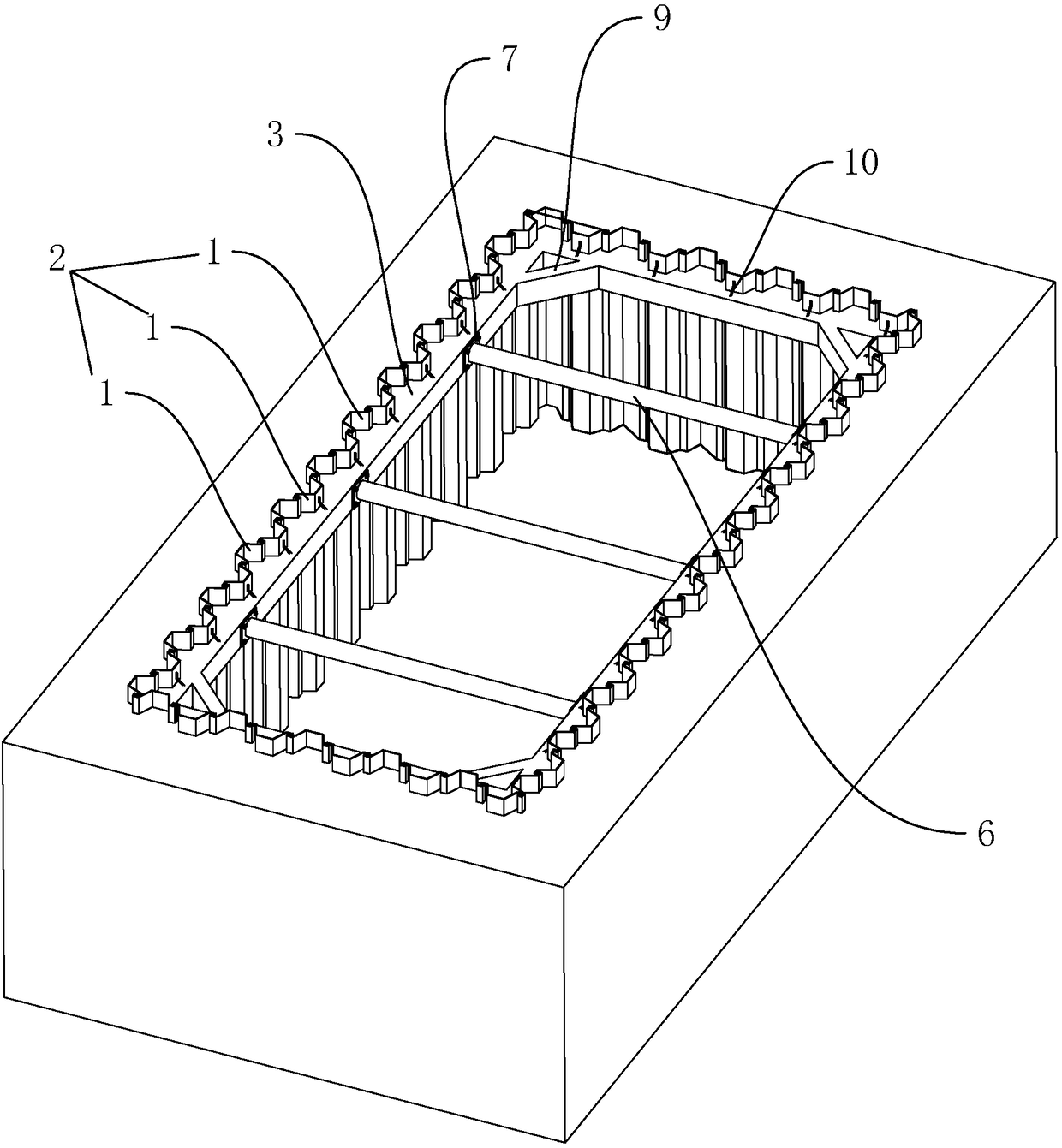

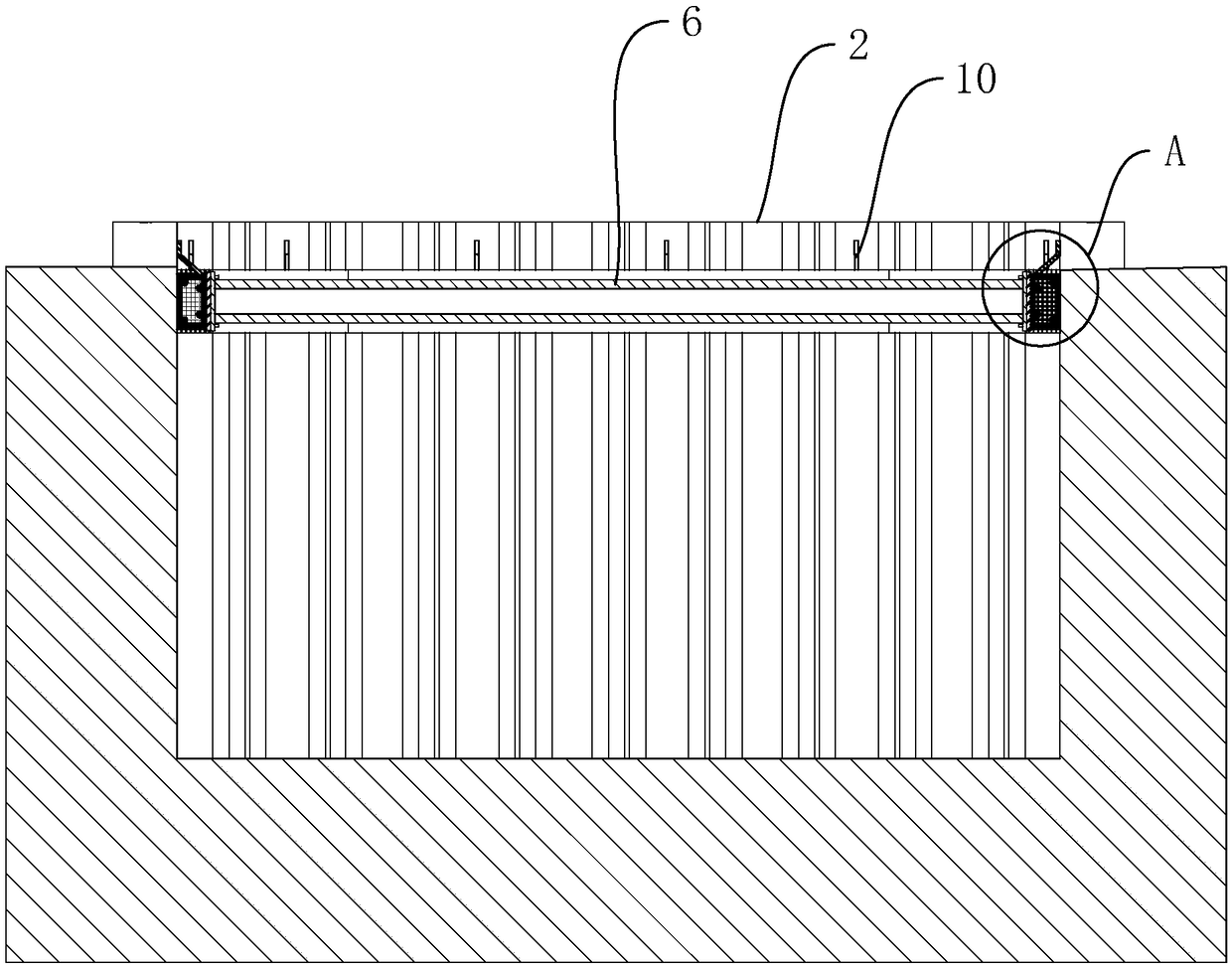

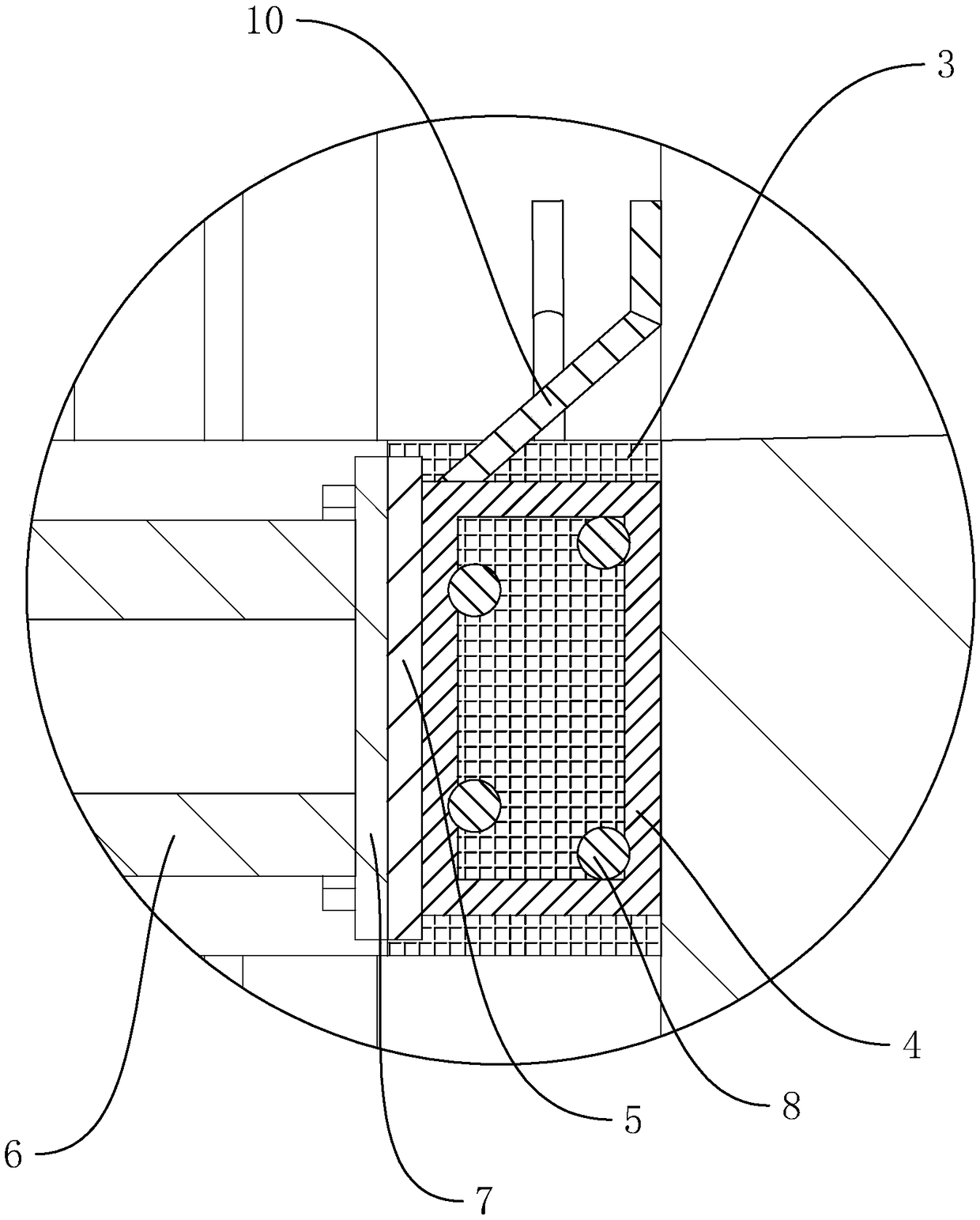

[0032] Embodiment 1: A support structure using Larsen steel sheet piles, such as figure 1 and figure 2 As shown, it includes several Larsen steel sheet piles 1 inserted on the ground, and several Larsen steel sheet piles 1 enclose a rectangular foundation pit enclosure 2, and the inner cavity of the foundation pit enclosure 2 is the foundation pit. And the four side walls of the foundation pit enclosure 2 are all poured with concrete beams 3, the concrete beams 3 are arranged horizontally, and the four concrete beams 3 are integrally formed, such as image 3 As shown, the side wall of the Larsen steel sheet pile 1 is also welded with a connecting piece 4, which is square and ring-shaped and made of round steel, and the connecting piece 4 is vertically arranged, and several connecting pieces 4 are located at the same horizontal position and It is poured into the concrete beams 3, wherein several groups of supporting components corresponding to the two concrete beams 3 are arr...

Embodiment 2

[0036]Embodiment 2: A construction method for foundation pit support, for the construction method of Embodiment 1: the construction method includes the following steps, step S1: first press several Larsen steel sheet piles 1 into the ground by a pile driver, and the pile driver It can be a vibrating pile hammer, which is used to press the Larsen steel sheet pile 1 into the ground, and ensure that several Larsen steel sheet piles 1 enclose a rectangular foundation pit enclosure 2, and make it close to the bottom surface of the Larsen steel sheet pile 1 Keep it flat; Step S2: Excavate the surface soil on the inner surface of the foundation pit enclosure 2, so that the upper part of the Larsen steel sheet pile 1 is exposed; Step S3: Weld the connecting piece 4 on the side wall of the Larsen steel sheet pile 1, and then connect the connecting piece 4 Weld diagonal stay rods 10 between Larsen steel sheet piles 1, and make all connecting pieces 4 at the same horizontal position, then...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com