Suspension type steel bar truss floor slab structure with detachable bottom formwork and construction method of suspension type steel bar truss floor slab structure

A steel truss and suspension technology, applied in the direction of floors, structural elements, building components, etc., to achieve the effects of reducing construction measures and labor costs, flat bottom, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the purpose, technical solution and advantages of the present invention clearer, the present invention will be further elaborated below in conjunction with the accompanying drawings.

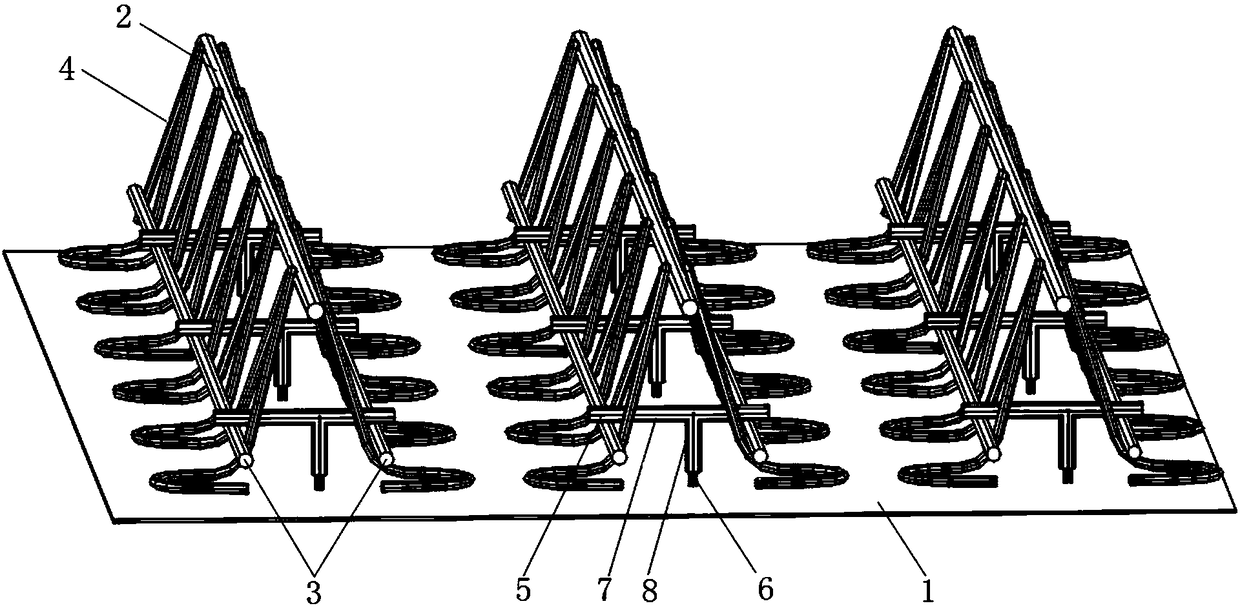

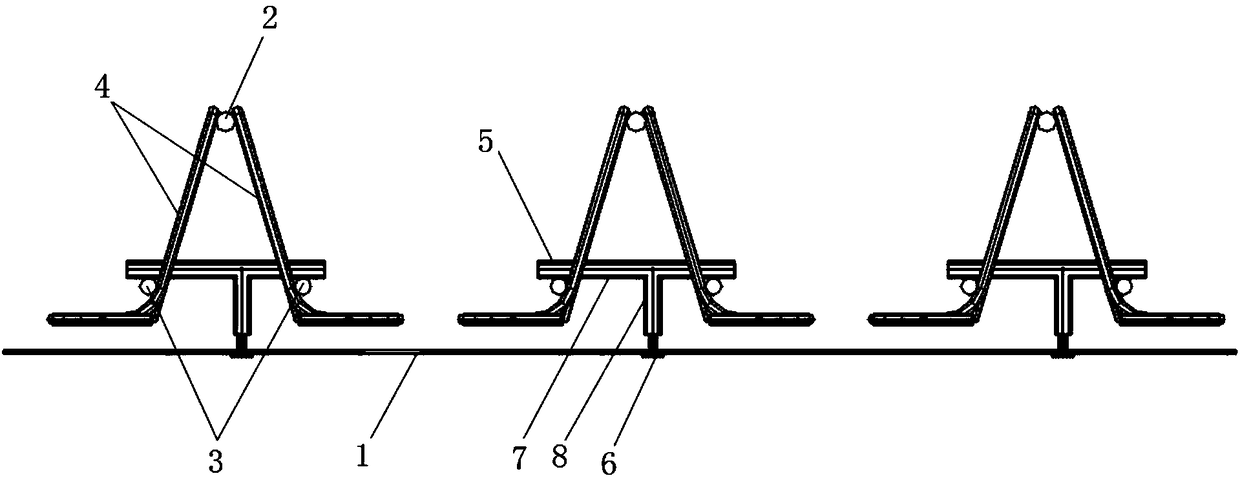

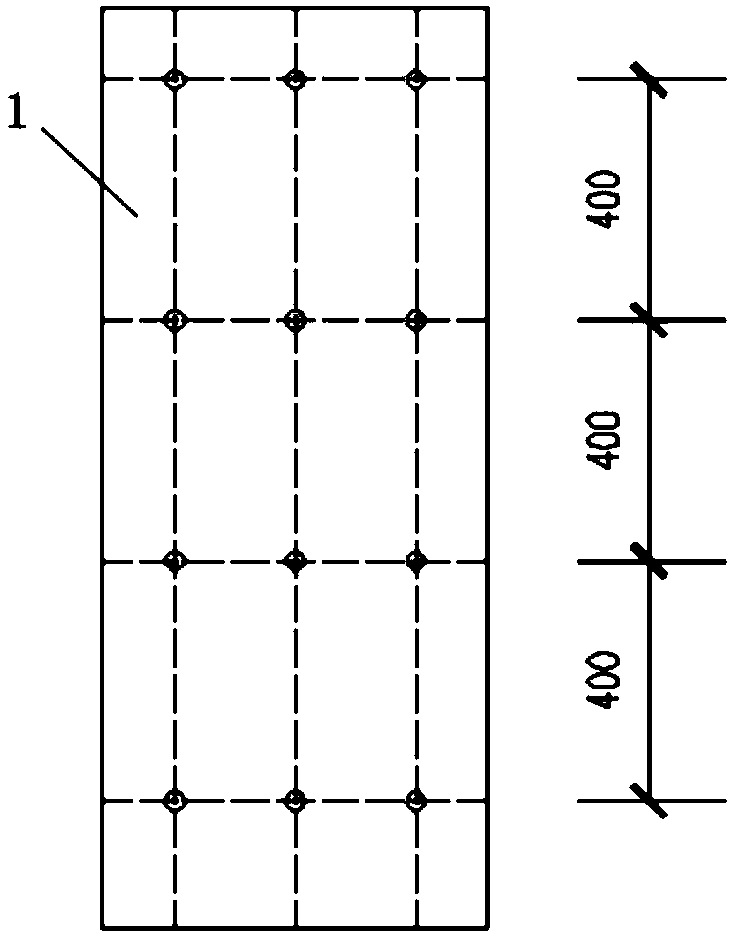

[0029] like figure 1 and figure 2 As shown, a bottom formwork detachable suspended steel truss floor slab structure includes a steel truss, a bottom formwork 1 and a T-shaped connecting member; the steel truss includes an upper chord steel bar 2, two lower chord steel bars 3 and several webs Rod steel bars 4, the one upper chord steel bar 2 and two lower chord steel bars 3 are arranged in parallel, and the web bar steel bars 4 are connected and fixed to the upper chord steel bars 2 and the lower chord steel bars 3; the T-shaped connecting member includes a T-shaped member 5 and a connecting screw 6. The T-shaped member 5 includes a "one"-shaped suspension rod 7 and a "|"-shaped connecting rod 8, and the bottom end of the "|"-shaped connecting rod 8 is threadedly fitted ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com