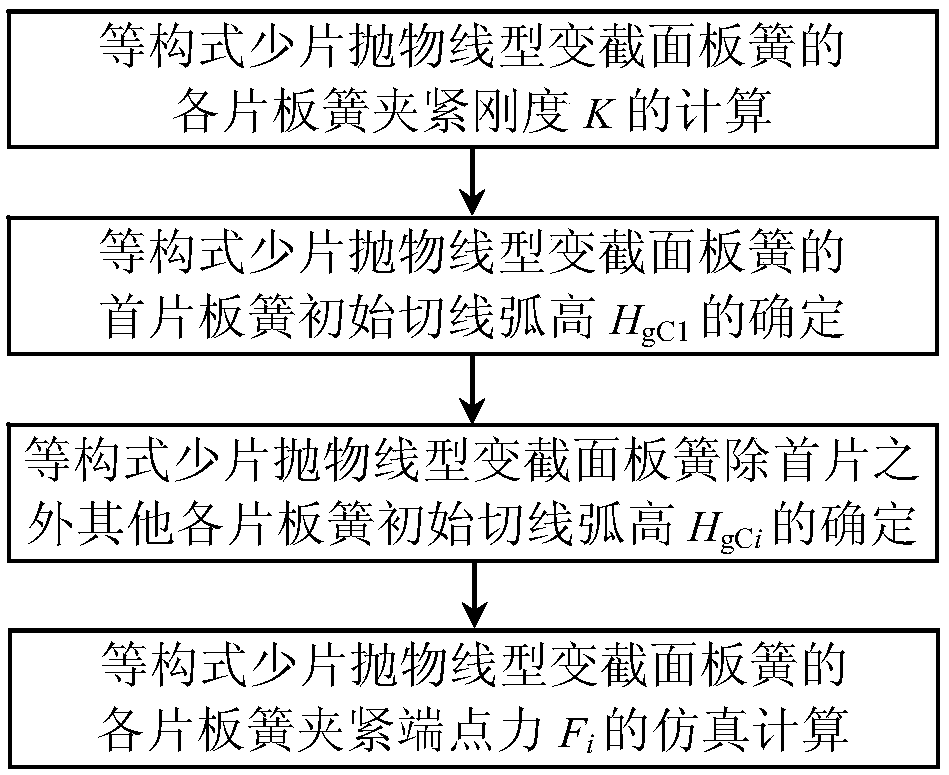

Simulation calculation method for clamping endpoint force of identically-structured few-leaf parabolic variable-section leaf springs

A simulation computing, parabolic technology, applied in computing, design optimization/simulation, special data processing applications, etc., can solve problems such as unreliable and unsatisfactory

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

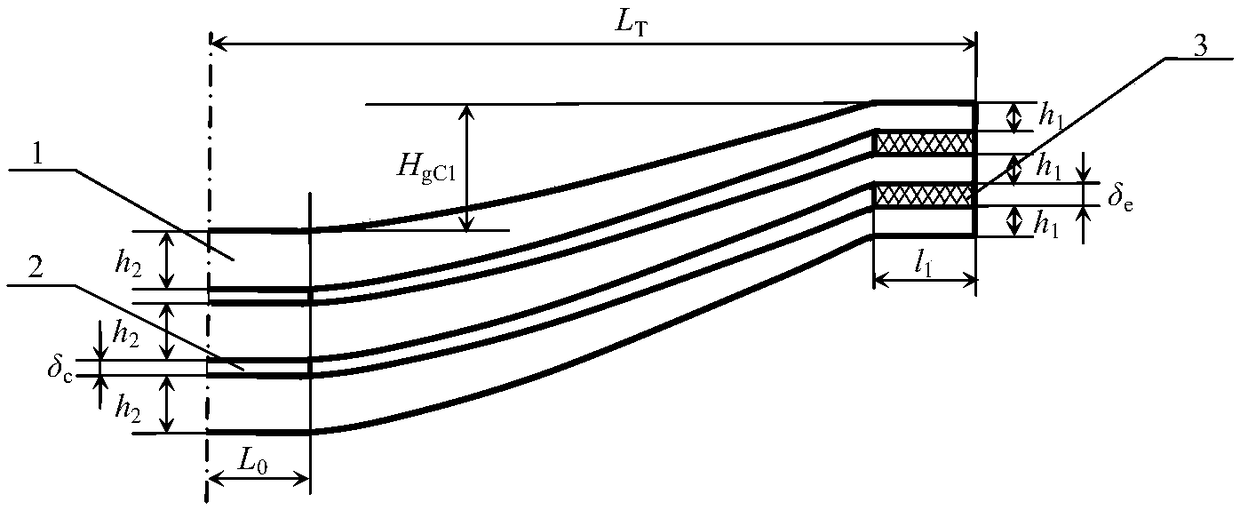

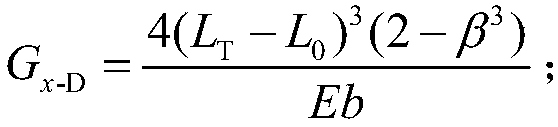

Embodiment 1

[0028] Embodiment 1: the width b=60mm of the few slices parabolic variable-section leaf spring of such-and-such construction, half span L T =570mm, half the length L of the straight section of the root clamped by the saddle bolt 0 =50mm, elastic modulus E=200GPa. The number of leaf springs n=3, the thickness h of the straight section at the root of each leaf spring 2 =18mm, the thickness h of the straight section at the end 1 =9mm, the thickness ratio of the parabola segment β=h 1 / h 2 =0.5, the design value H of the free tangent arc height of each leaf spring g10 =87.4mm,H g20 =96.00mm, H g30 =98.60mm. Root gasket thickness δc =3mm, end gasket thickness δ e = 6mm. According to the number of leaf springs, the structural parameters of each leaf spring, the design value of the free tangent arc height, elastic modulus, the thickness of the root gasket and the end gasket, the number of parabolic variable-section leaf springs of the same construction After assembly and cl...

Embodiment 2

[0050] Embodiment two: the width b=60mm of equal-structure few-piece parabolic variable-section leaf spring, half span L T =570mm, half the length L of the straight section of the root clamped by the saddle bolt 0 =50mm, elastic modulus E=200GPa. The number of leaf springs n=4, the thickness h of the straight section at the root of each leaf spring 2 = 16mm, the thickness h of the straight section at the end 1 =8mm, the thickness ratio of the parabola segment β=h 1 / h 2 = 0.5. The design value H of the free tangent arc height of each leaf spring g10 =92.2mm,H g20 =99.1mm, H g30 =100.9mm, H g40 = 102.8 mm. Root gasket thickness δ c =3mm, end gasket thickness δ e = 6mm. According to the number of leaf springs, the structural parameters of each leaf spring and the design value of the free tangent arc height, modulus of elasticity, thickness of the root gasket and end gasket, for the same configuration of few-piece parabolic variable-section leaf spring After assembly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com