Follow-up laser shock peening processing device and method

A laser shock strengthening and follow-up technology, which is applied in the field of material processing, can solve problems such as water film instability and achieve the effect of efficient laser shock strengthening treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] The present application is described in detail below in conjunction with the examples, but the present application is not limited to these examples.

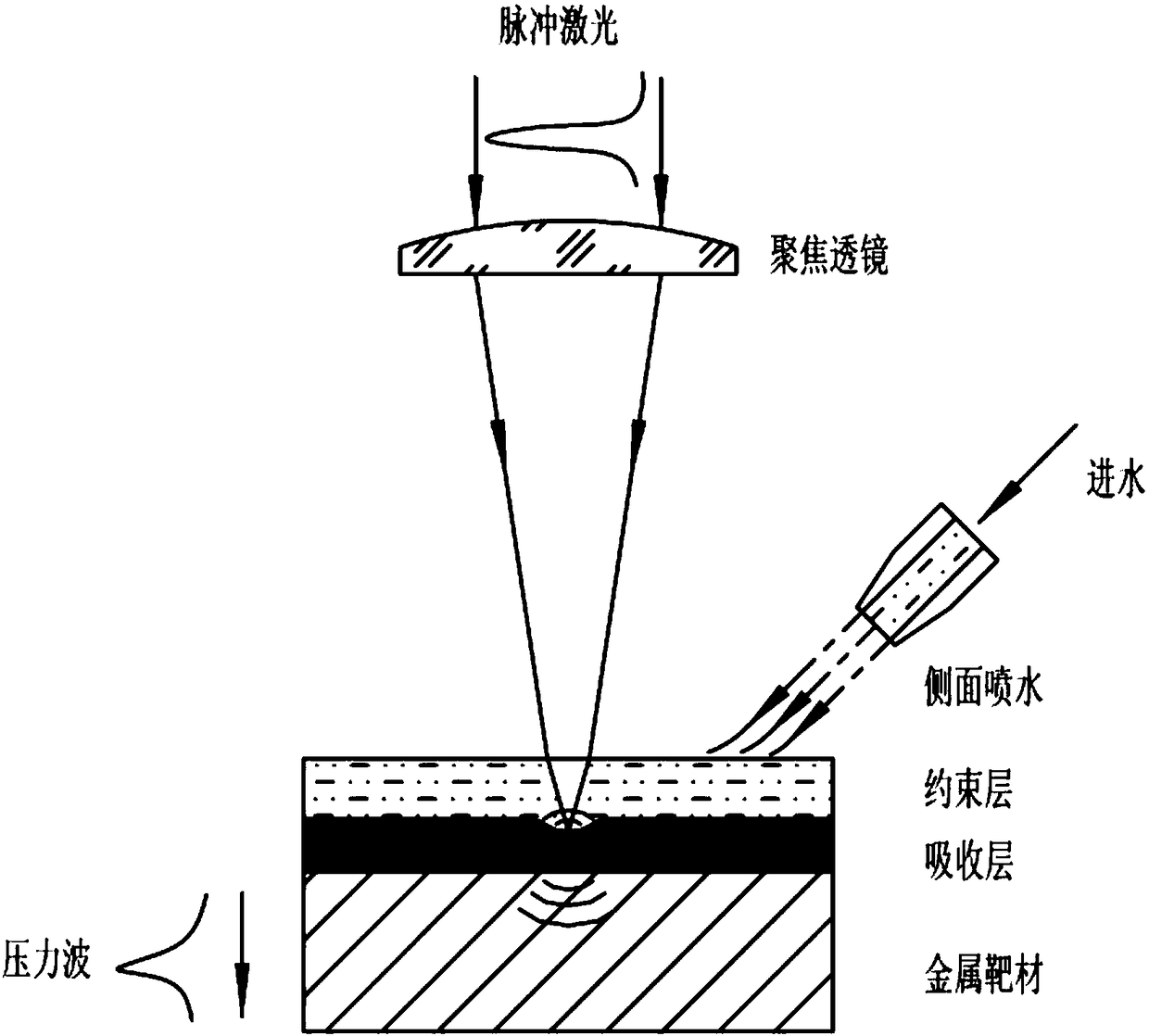

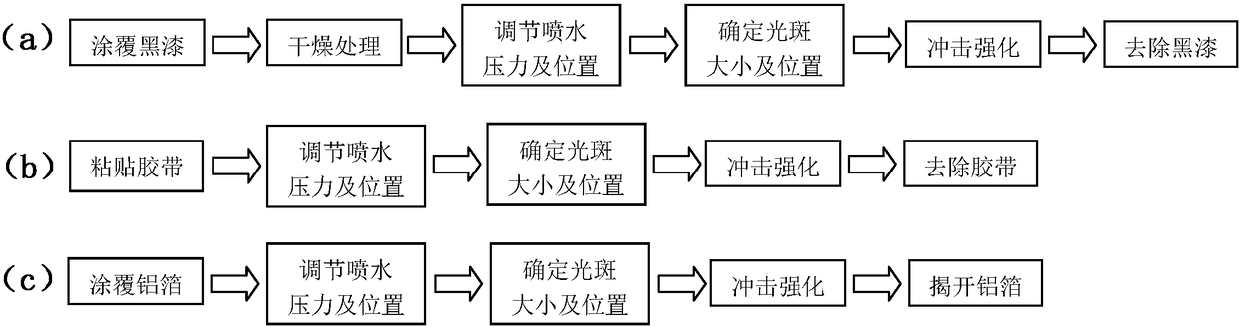

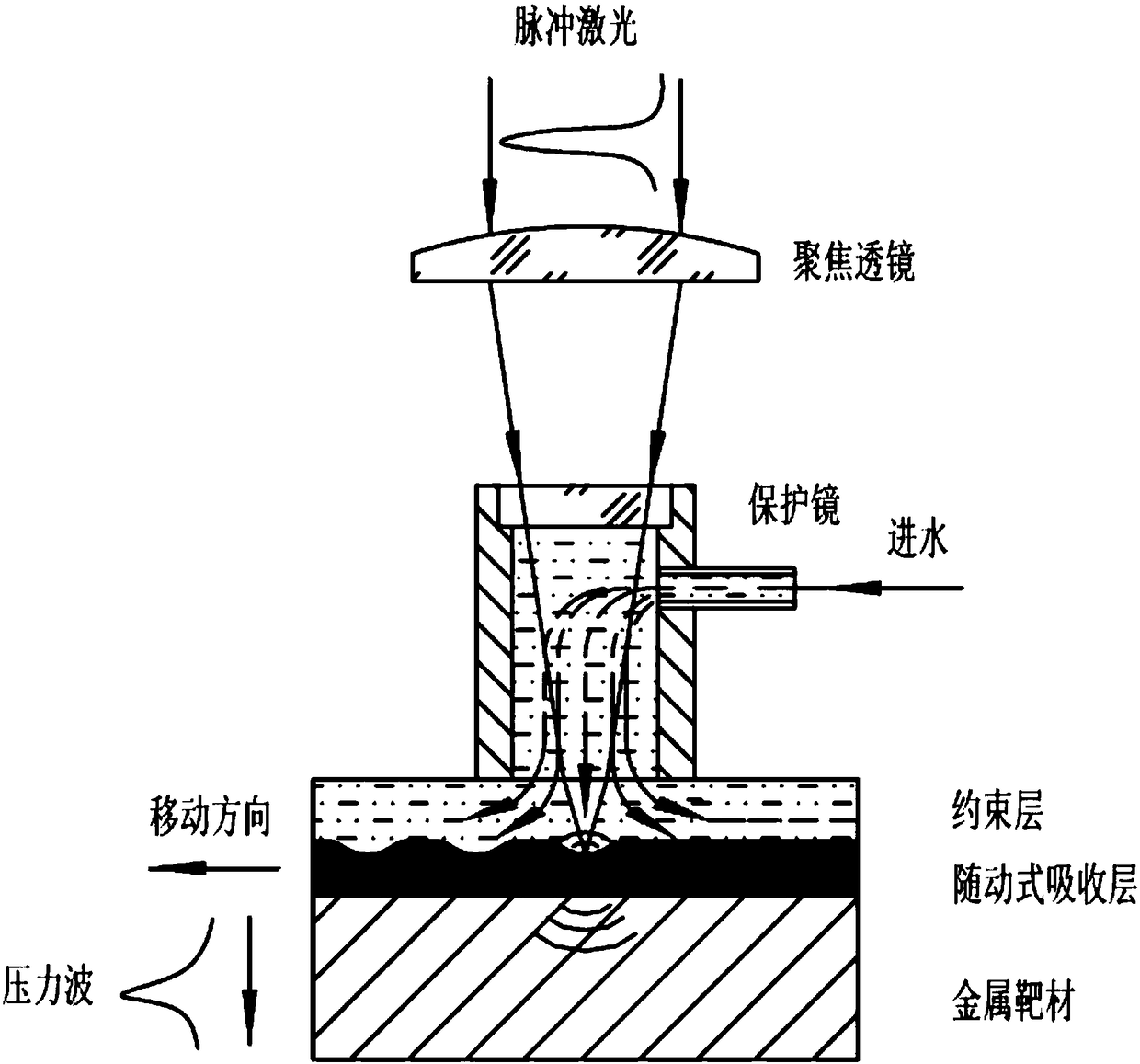

[0064] like Figure 3 to Figure 8 As shown, when the follow-up laser shock peening device of the present application works, the laser shock peening device utilizes a short laser pulse (50 nanoseconds in pulse width) and a power density of 2GW / cm 2 The 532nm pulsed laser light passes through the transparent confinement layer (water in this application) and acts on the absorption band on the surface of the workpiece. After the absorption band absorbs the laser energy, it quickly gasifies to form a dense high-temperature, high-pressure plasma, which expands rapidly and forms a shock wave. The shock wave intensity can reach several GPa (10 9 Pa) magnitude, which is much higher than the yield strength of many workpiece materials; the shock wave passes through the absorbing protective layer, acts on the surface of the workpiec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com