Novel electric shearing machine structure

An electric shear and motor technology, applied in metal processing and other directions, can solve problems such as the weight of the whole machine, affecting the service life of the motor, and the inability of heat to be effectively dissipated.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

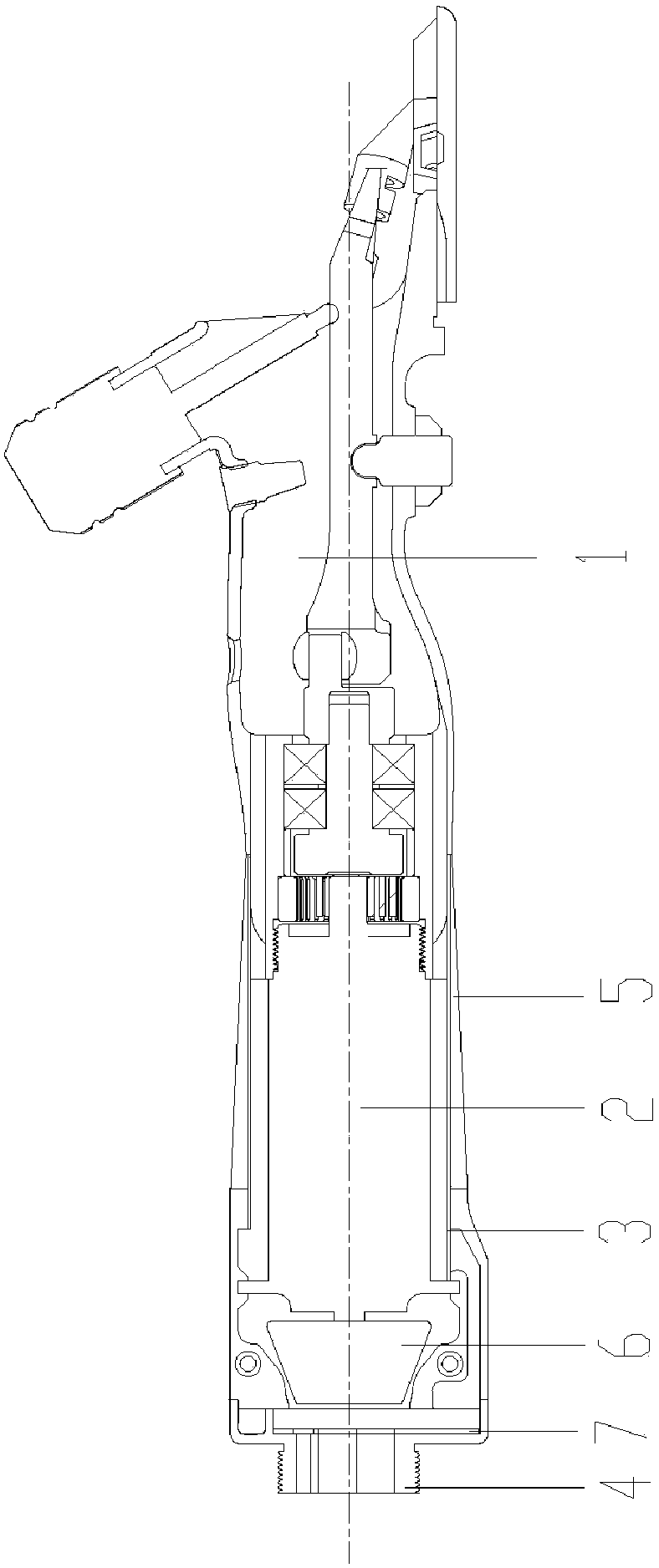

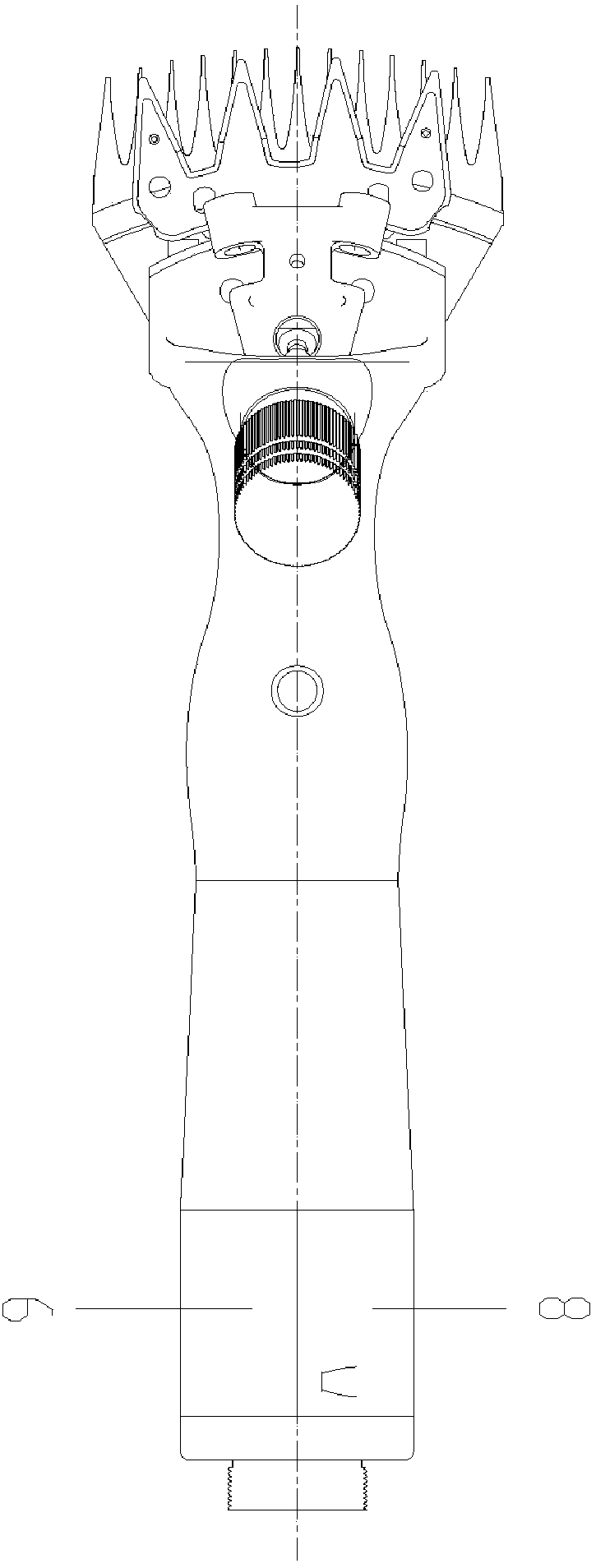

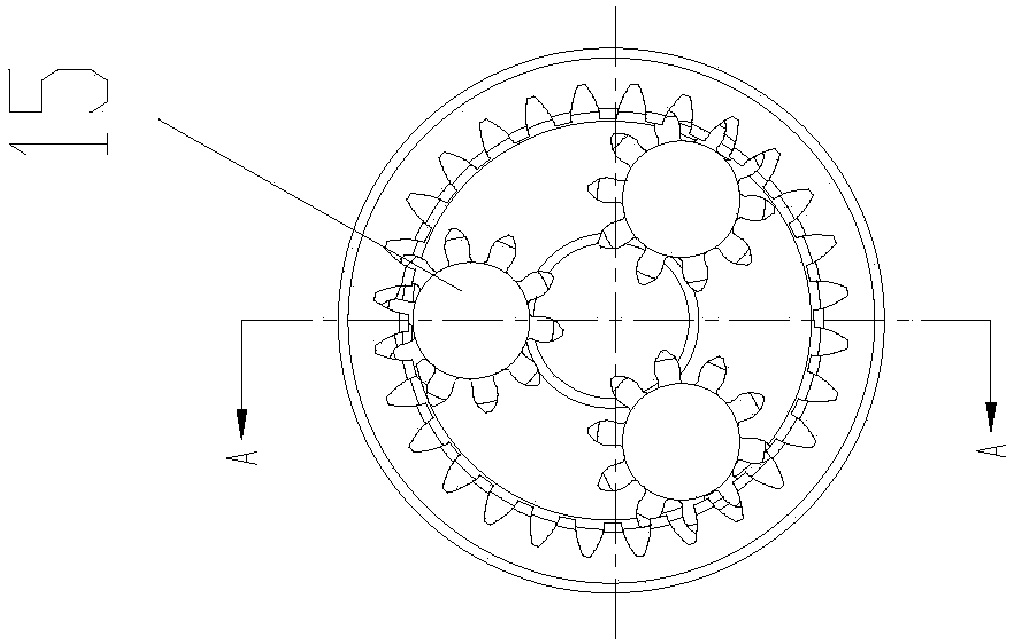

[0040] A new type of electric shearing machine structure, such as Figure 1 to Figure 4 As shown, it includes a motor 2, a cylinder 3, a connection socket 4, a planetary reducer and a fan 6 composed of a planetary carrier 13, a planetary gear 15, and a planetary shaft 16; it also includes a metal machine head body 1, a silicone sleeve 5, and a fan 6. Wiring board 7, right rear end cover 8, left rear end cover 9, ring gear 10, gasket 11, bearing 12, eccentric shaft 14; external thread and metal machine head provided on the circular power output end of motor 2 The internal threads provided in the inner hole of the rear part of the body 1 are assembled together in a threaded manner; the outer circle of the metal machine head body 1 is provided with several upwardly protruding first reinforcing ribs and air holes penetrating from the outside to the inside. The flowing air generated by the rotation of the fan 6 enters from the rear of the whole structure, and flows out from the ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com