A preparation method of fluorescent tracer polymer microgel profile control and water shutoff agent

A technology of profile control and water blocking agent and fluorescent tracer, which is applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve the problem that the polymer microgel profile control agent cannot be effectively traced and the concentration of the produced fluid cannot be detected. Accurate, difficult to characterize structural changes, etc., to avoid aggregation-induced fluorescence quenching, low cost, and strong functionality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

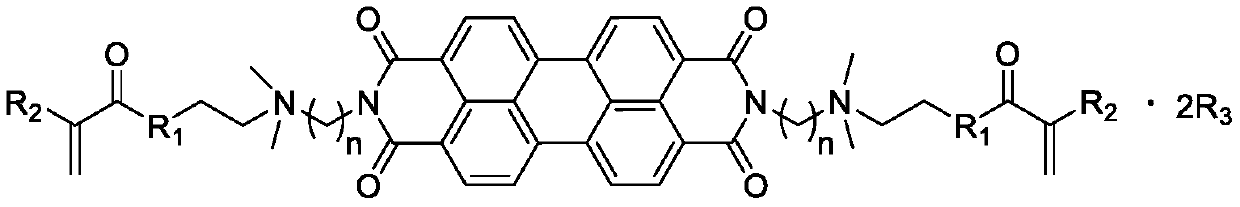

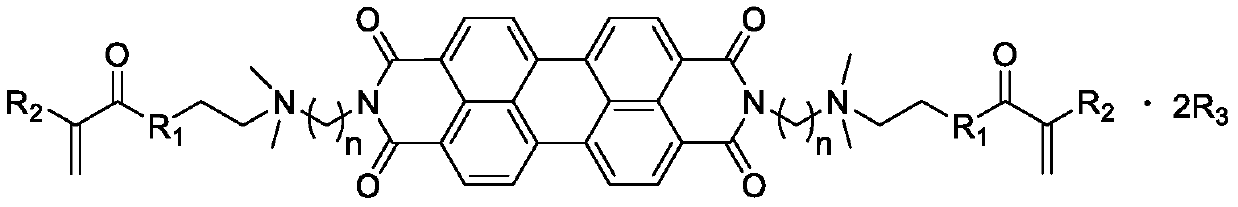

[0033] Step 1. Mix 150 g of acrylamide, 50 g of methacrylic acid, 0.5 g of perylene diimide quaternized cross-linking monomer as cross-linking agent A and 220 g of deionized water, and stir at room temperature to obtain a mixed solution 1;

[0034] Step 2, 100g sorbitan glyceride, 40g sorbitan monooleate polyoxyethylene ether and 350g diesel oil are mixed to obtain mixed solution 2;

[0035] Step 3: Add the mixed solution 1 into the mixed solution 2 at an emulsification stirring speed of 1200 rpm, emulsify at room temperature for 30 minutes, reduce the stirring speed to 400 rpm, and deoxygenate with nitrogen for 20 minutes, Put the above mixed solution in a water bath at 10°C, add 3g of potassium persulfate and 1g of sodium ascorbate to initiate the polymerization reaction, and react at a constant temperature of 70°C for 4 hours to obtain the fluorescent tracer polymer microgel profile control and water shutoff agent YH-1 .

[0036] Using the Malvern dynamic light scattering ...

Embodiment 2

[0038] Step 1. Mix 130 g of acrylamide, 40 g of acrylic acid, 0.5 g of perylene diimide quaternized cross-linking monomer as cross-linking agent A and 200 g of deionized water, and stir at room temperature to obtain a mixed solution 1;

[0039] Step 2, 60g sorbitol glyceride, 20g octylphenol polyoxyethylene ether and 350g diesel oil are mixed to obtain mixed solution 2;

[0040] Step 3: Add the mixed solution 1 into the mixed solution 2 at an emulsifying stirring speed of 1200 rpm, and emulsify at room temperature for 30 minutes. Reduce the stirring speed to 400 rpm, remove the dissolved oxygen in the water with nitrogen gas for 20 minutes, put the above mixed solution in a water bath at 10°C, add 3g of ammonium persulfate and 3g of sodium pyrosulfite to initiate the polymerization reaction, and react at a constant temperature of 70°C for 4 Hours, traced polymer microgel profile control and water shutoff agent YH-2 was obtained.

[0041] Using a laser scanning confocal fluore...

Embodiment 3

[0043]Step 1. Mix 120g acrylamide, 60g sodium 2-acrylamido-2-methylpropanesulfonate, 0.4g perylene diimide quaternization crosslinking monomer (crosslinking agent A) and 200g deionized water , stirred at room temperature to obtain the mixed solution 1;

[0044] Step 2: Mix 40 g of sorbitan trioleate, 10 g of sorbitan monooleate polyoxyethylene ether and 300 g of diesel oil to obtain a mixed solution 2.

[0045] Step 3: Add the mixed solution 1 into the mixed solution 2 at an emulsifying stirring speed of 1200 rpm, and emulsify at room temperature for 15 minutes. Reduce the stirring speed to 400 rev / min, pass nitrogen gas to remove oxygen for 20 minutes, put the above mixed solution in a water bath at 10°C, add 3g of ammonium persulfate and 3g of ethanolamine to initiate the polymerization reaction, and react at a constant temperature of 70°C for 4 hours to obtain tracer Type polymer microgel profile control and water shutoff agent YH-3.

[0046] Using a laser scanning confoc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com