Replaceable energy-dissipating column base joint for fabricated integral frame

A technology of column foot joints and frame columns, which is applied in the field of replaceable energy-consuming composite column structure systems, can solve the problems of few research results on assembled integral frame structure systems, improve operability, increase installation efficiency, and reduce construction difficulty Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to better understand the above technical solutions of the present invention, a further detailed description will be given below in conjunction with the drawings and embodiments.

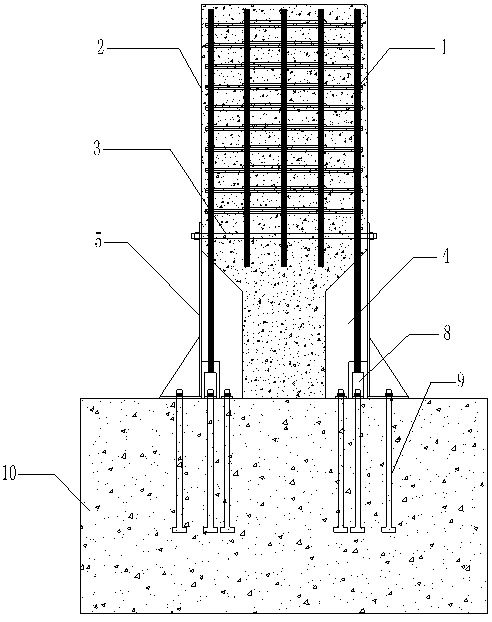

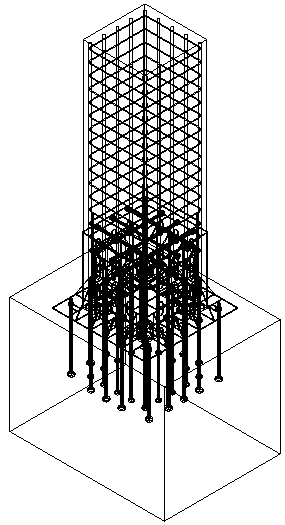

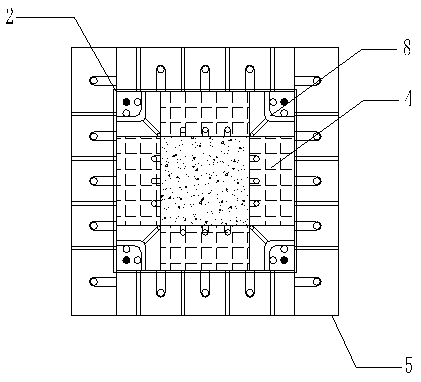

[0026] Such as figure 1 As shown, an assembled integral frame replaceable energy-dissipating column base node mainly includes a rectangular prefabricated frame column 2 , four replaceable energy-dissipating standard steel members 4 , and four replaceable energy-dissipating combined steel plates 5 . The feet of the rectangular prefabricated frame column 2 are recessed from four surfaces to ensure that the longitudinal ribs 1 at all corners of the rectangular prefabricated frame column 2 are continuous, and the longitudinal ribs 1 at the corners of the rectangular prefabricated frame column 2 are connected to the column foot connector 8 The additional steel bars are lapped to meet certain structural requirements, and are connected with the high-strength screw 9 pre-buried in the cast-in...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap