Ceiling light special for D type ceiling and mounting process of ceiling light

A technology for ceiling and ceiling lamps, which is applied in the field of ship electrical and outfitting, can solve the problems of inconvenient installation and waste of ceiling materials, and achieve the effects of stable structure, high adaptability and beautiful appearance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

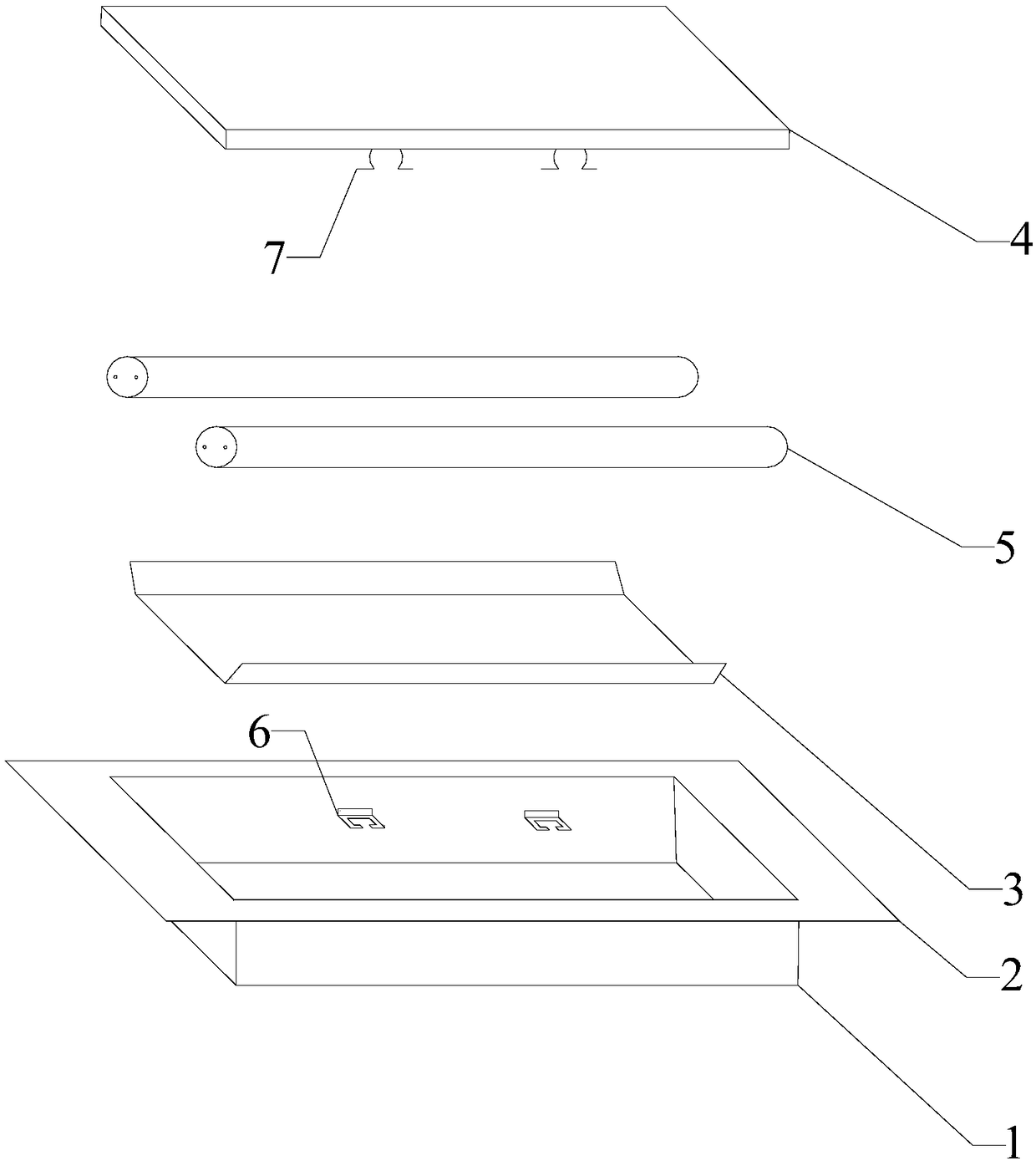

[0043] Please refer to figure 1 and figure 2 Shown, embodiment one of the present invention is:

[0044]A dome lamp dedicated to a D-shaped ceiling, comprising a housing 1, a frame 2, a reflector 3, a lamp panel 4 and a lamp tube 5. The outline of the housing 1 is a cuboid and one end of the housing 1 has an opening. The housing 1 The outer diameter of the body 1 is adapted to the inner diameter of the installation opening of the D-shaped ceiling. The frame 2 is sleeved on the opening end of the housing 1 and fixed with the housing 1. The inner side of the bottom plate of the housing 1 is connected with the shell The inner studs of the bottom plate of the body 1 are perpendicular to each other, the reflector 3 is connected with the inner side of the bottom plate of the housing 1 through the inner studs, and the two ends of the reflector 3 and the two short sides of the housing 1 are respectively A lamp holder and a starter are provided, and the lamp holder and the starter a...

Embodiment 2

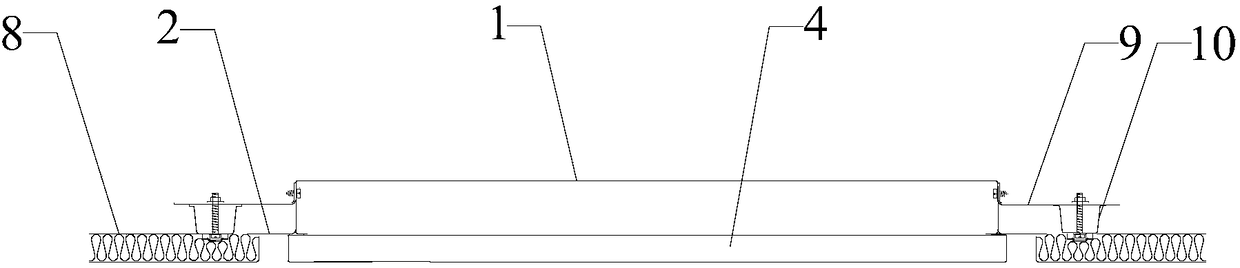

[0047] A dome lamp dedicated to a D-shaped ceiling, which has the following features on the basis of Embodiment 1: It also includes an L-shaped angle steel 9, the number of which is two, and the two angle steels 9 are respectively symmetrically arranged on the housing 1, the angle steel 9 is composed of a first steel plate and a second steel plate perpendicular to each other, the first steel plate and the second steel plate are rectangular and the long side end of the first steel plate is connected to the long side end of the second steel plate connected, the first steel plate is connected to the outside of the side wall of the housing 1, a hanging beam 10 is provided between the second steel plate and the cover plate 8, and the second steel plate passes through the connection between the hanging beam 10 and the cover plate 8 Inner surface connection.

[0048] During installation, the frame 2 is fixed on the upper surfaces of two adjacent cover plates 8, the second steel plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com