Miniature biology intelligent-structure optical 3D image module and manufacturing process thereof

An intelligent structure and micro-biological technology, applied in lasers, laser parts, semiconductor lasers, etc., can solve the problems of blurred focus, image shift, affecting image quality, etc., to improve production efficiency and product yield, fast focus and Assemble and ensure the effect of image quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with specific embodiment, further illustrate the present invention, should be understood that these embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention, after having read the present invention, those skilled in the art will understand various equivalent forms of the present invention All modifications fall within the scope defined by the appended claims of the present application.

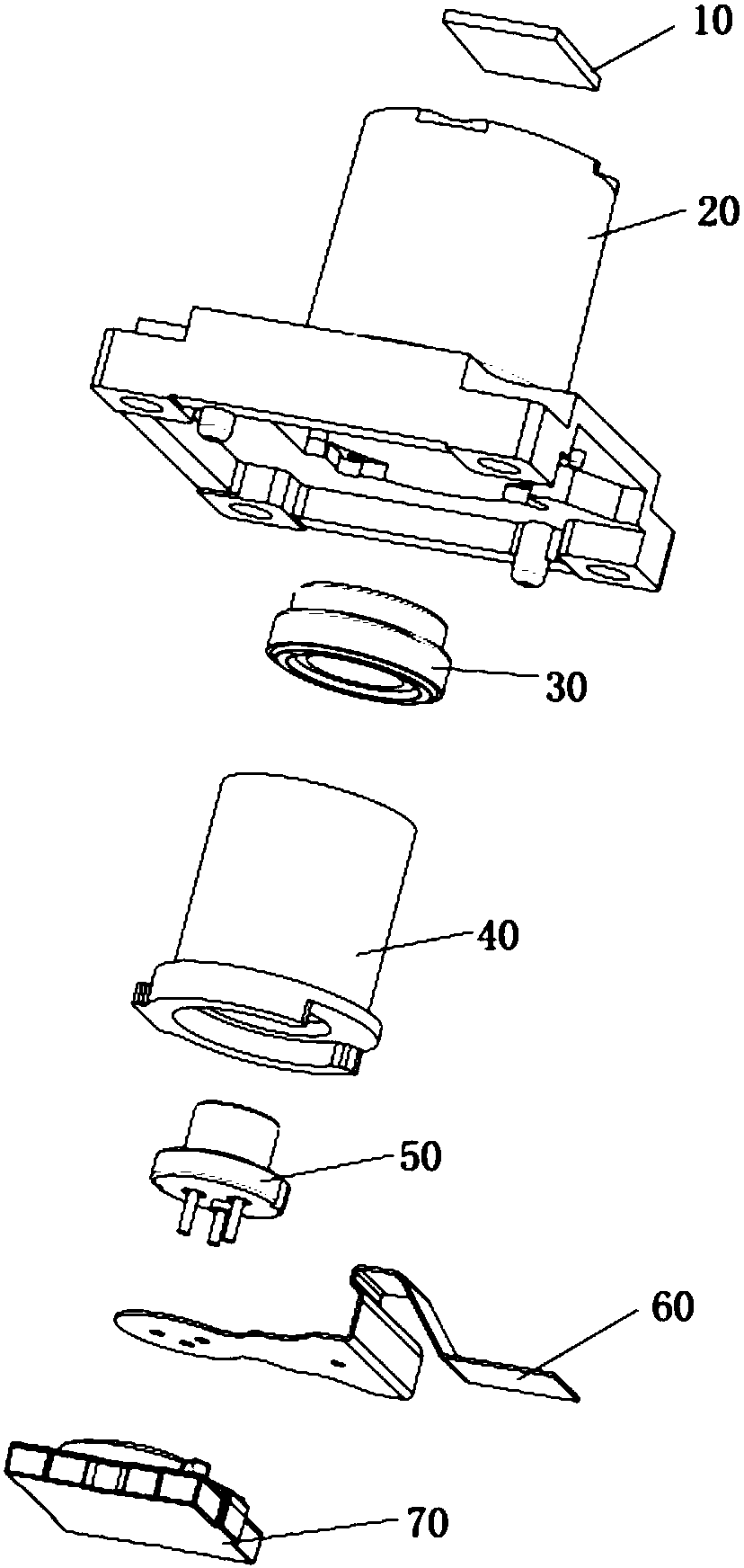

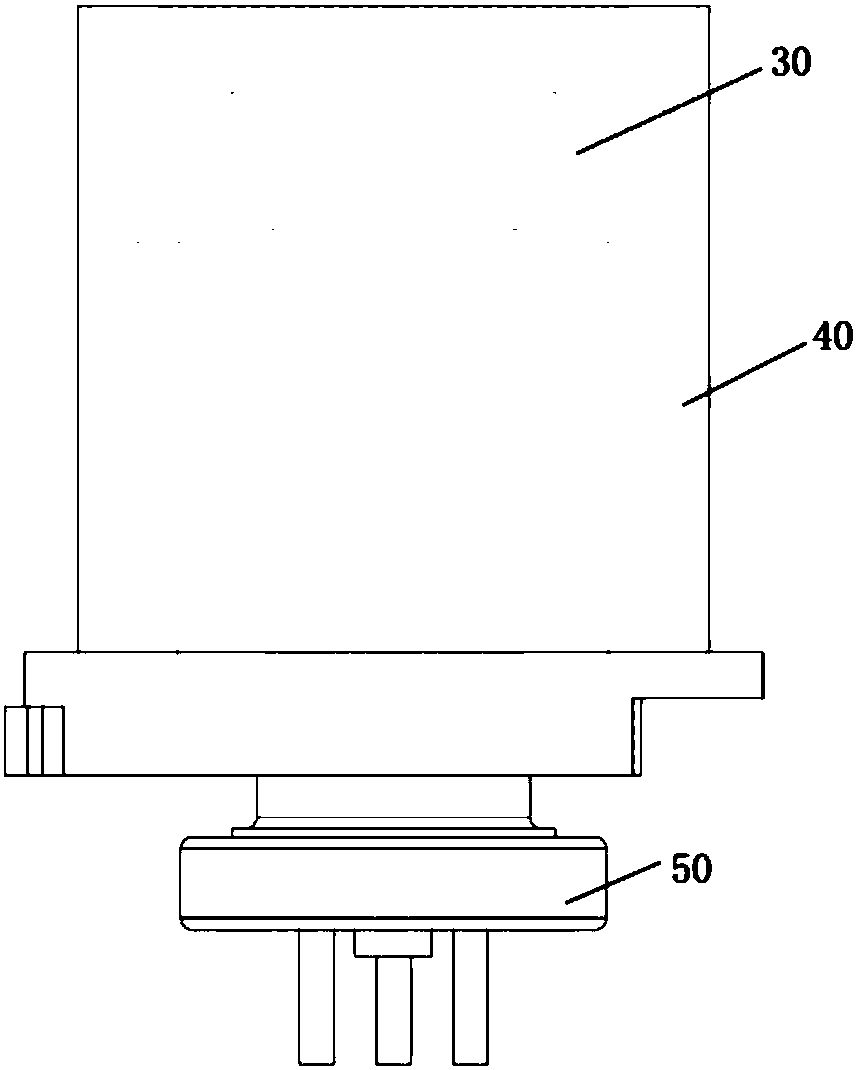

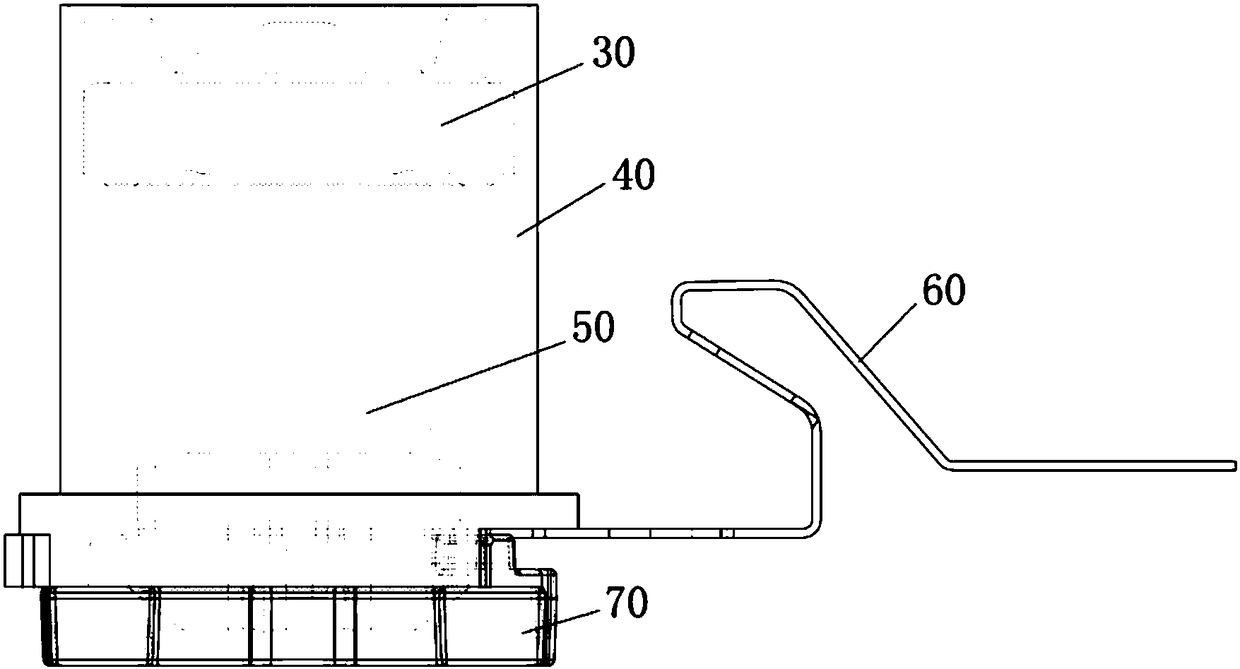

[0029] Such as Figure 1-3 As shown, a miniature biological intelligent structured light 3D image module disclosed in the embodiment of the present invention includes a laser diode 50, a lens 30, a copper base 40, a flexible circuit board 60 (FPC), a heat sink 70, a plastic base 20 and Diffractive optical element 10. Wherein, the copper base 40 is a hollow cylindrical integrally formed copper base 40 , and the laser diode 50 and the lens 30 are respectively embedded in two ends of the copper base...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap