Box structure based on riveting

A box structure and riveting technology, which is applied in the field of rail vehicles, can solve problems such as difficulty in guaranteeing dimensional accuracy, few procurement channels, and heavy workload, and achieve the effects of guaranteed sealing level, high dimensional accuracy, and short production hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

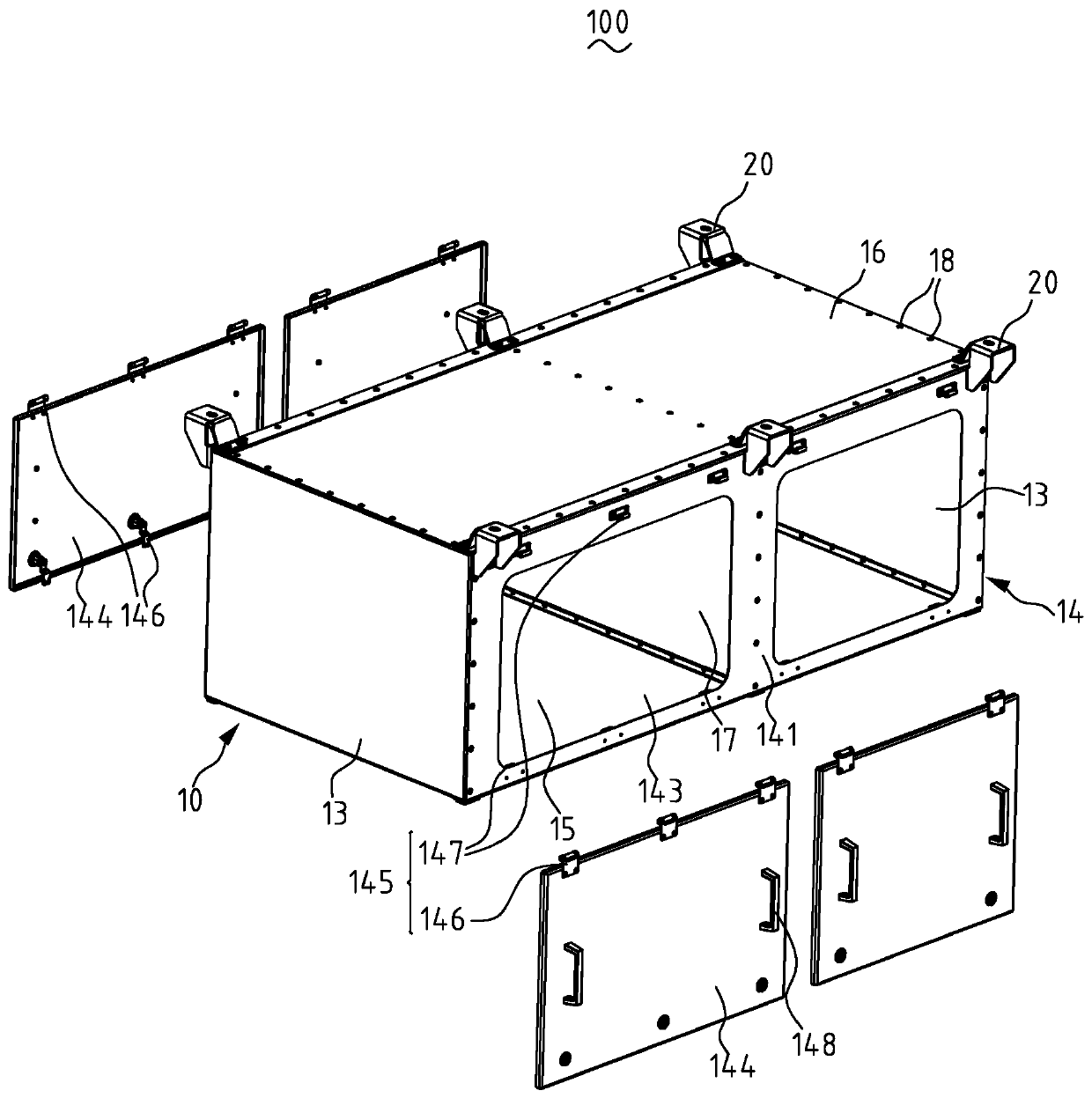

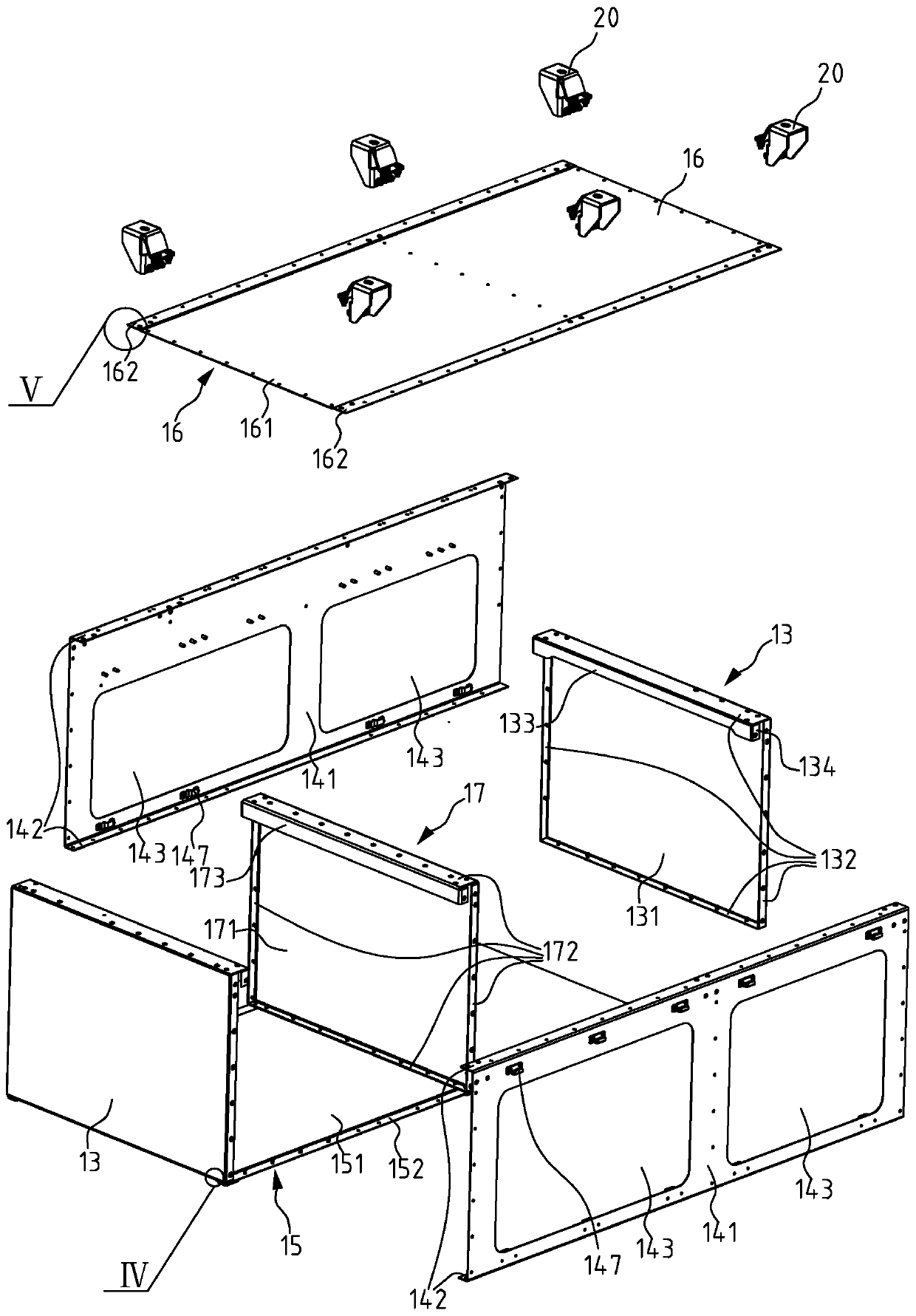

[0022] In order to make the purpose, technical solution and advantages of the present invention clearer, the embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

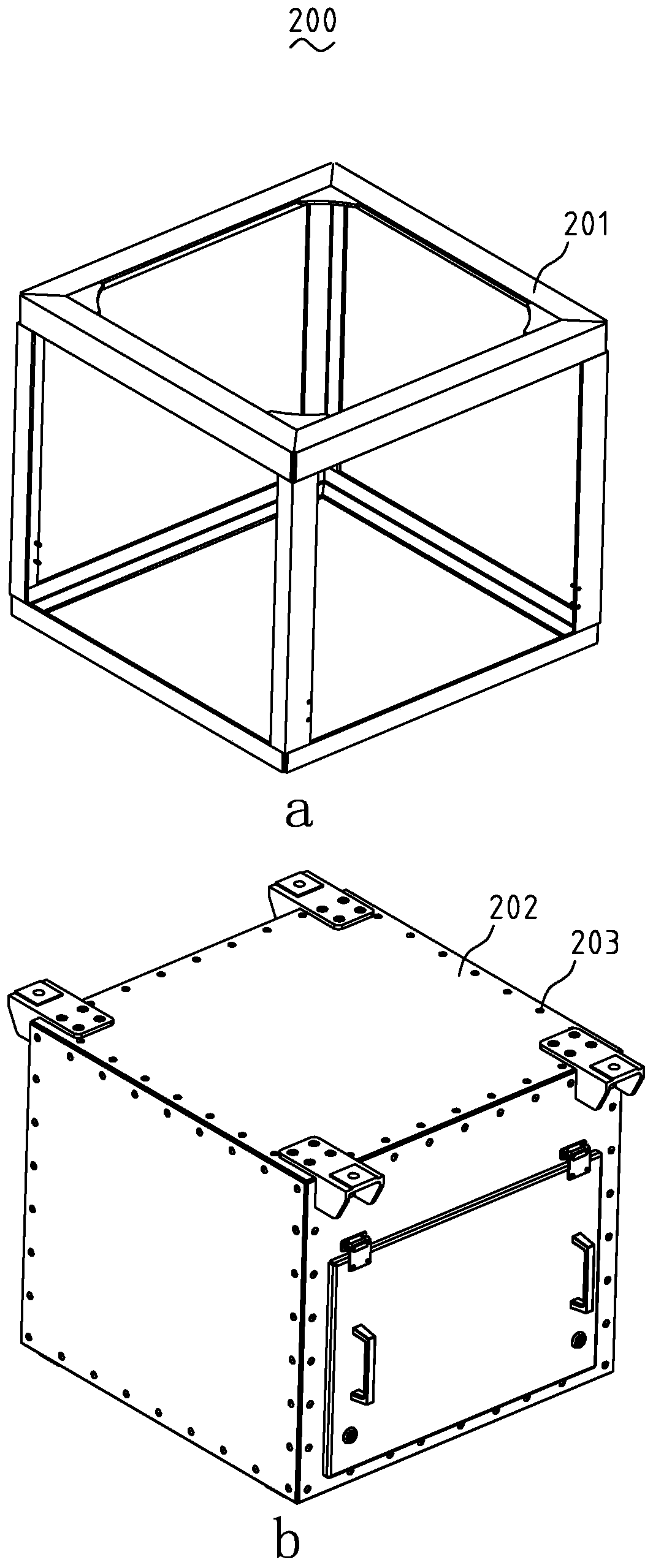

[0023] figure 2 It is a structural schematic diagram of the box structure based on riveting of the present invention, image 3 is a disassembled view of a riveted-based box structure without a door panel. Specifically, see Figure 2 to Figure 3 , the box structure 100 based on riveting of the present invention includes a box body 10 and lifting lugs 20 .

[0024] The box body 10 includes a first vertical board 13 , a second vertical board 14 , a bottom board 15 , a top board 16 , a middle partition board 17 , and rivets 18 .

[0025] There are two first vertical plates 13 arranged vertically and parallel to each other at intervals. The first vertical plate 13 includes a first vertical plate body 131 , a first bending portion 132 , and a rei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com