Pipe support frame

A technology of support frame and pipe frame, applied in the direction of pipe support, pipe/pipe joint/pipe fitting, mechanical equipment, etc., can solve the problems of small adaptability and cannot be adjusted according to needs, etc., to achieve the effect of convenient laying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

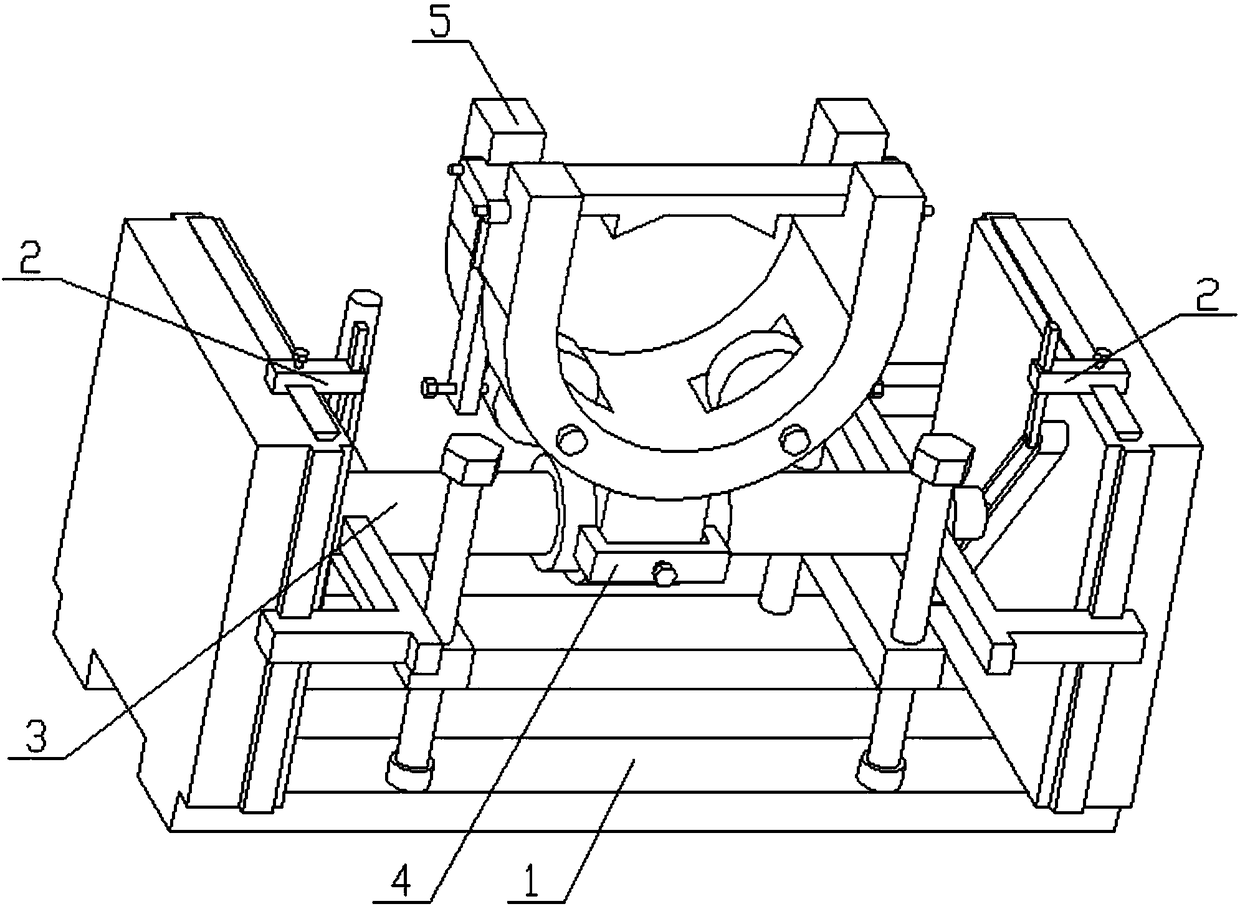

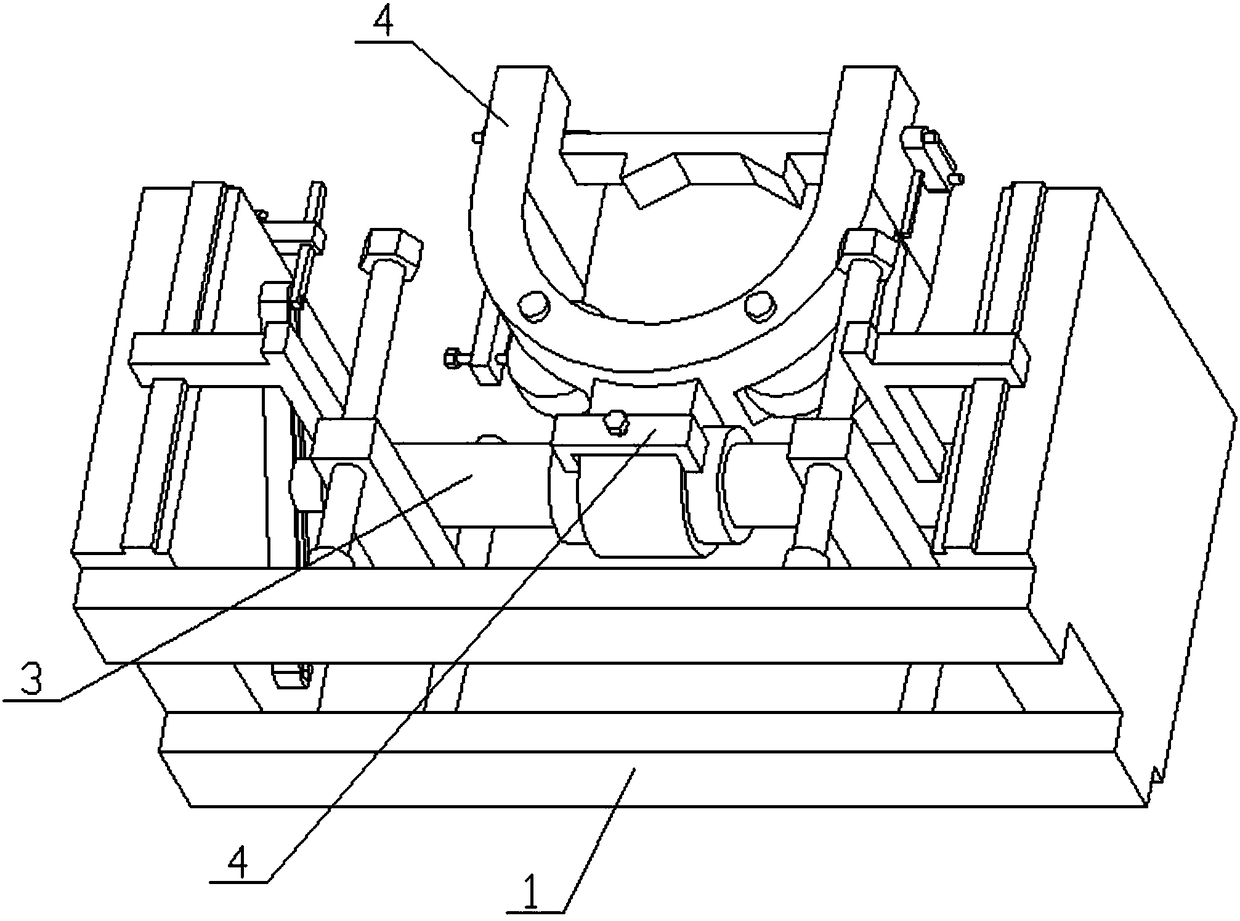

[0026] Combine below Figure 1-10 This embodiment is described. The present invention relates to the field of pipeline laying engineering, more specifically, a pipeline support frame, which includes a frame assembly 1, a groove bar assembly 2, a horizontal frame assembly 3, a positioning piece 4, and a pipe frame 5. The device supports The height and left and right positions of the pipeline can be adjusted, and the device can adapt to the laying of inclined pipelines at a certain angle to the ground, and the pipeline can be rotated on the device, which is convenient for the laying of pipelines that need to be connected by threads.

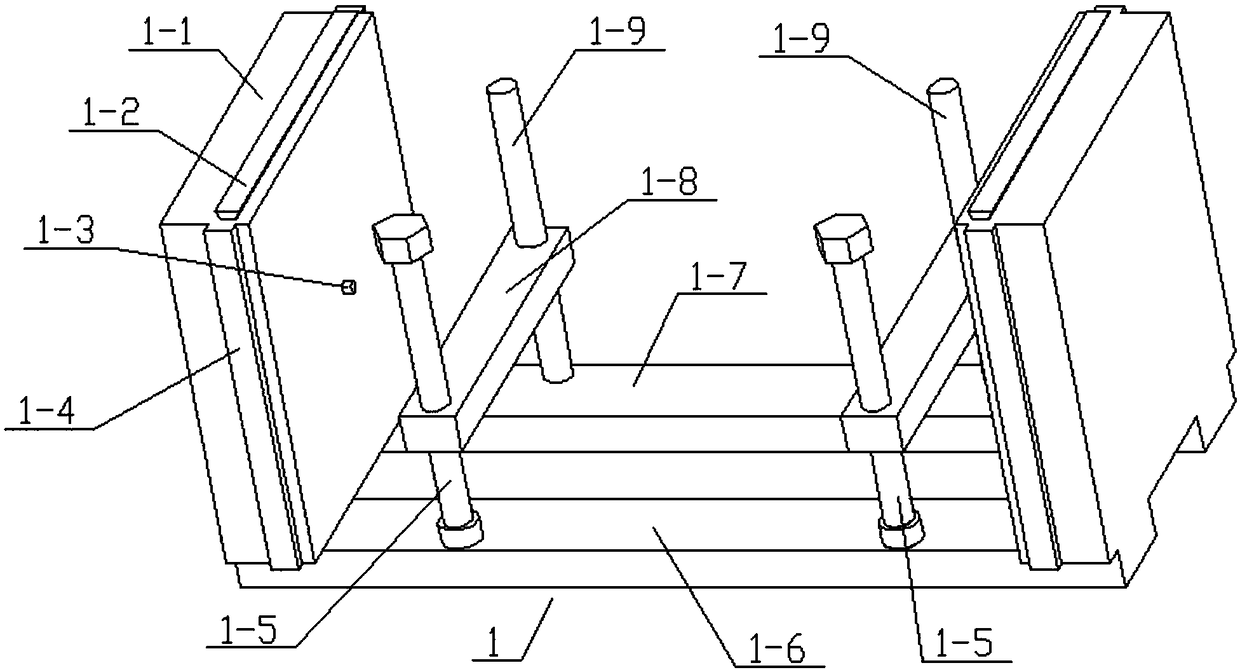

[0027] The frame assembly 1 includes a side plate 1-1, a trapezoidal convex strip 1-2, a cylindrical convex strip 1-3, a rectangular convex strip 1-4, a front bottom strip 1-6 and a rear bottom strip 1-7, the side There are two boards 1-1, a rear bottom strip 1-7 is fixedly connected between the rear ends of the lower ends of the two side boards 1-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com