LED lamp

A technology of LED lamps and LED circuit boards, applied in lighting and heating equipment, instruments, mechanical equipment, etc., can solve the problems of unsuitable flat LED lamps, LED lamp brightness enhancement, and unsuitable LED lamps, etc., to achieve the utilization rate of light High, uniform lighting, small footprint effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

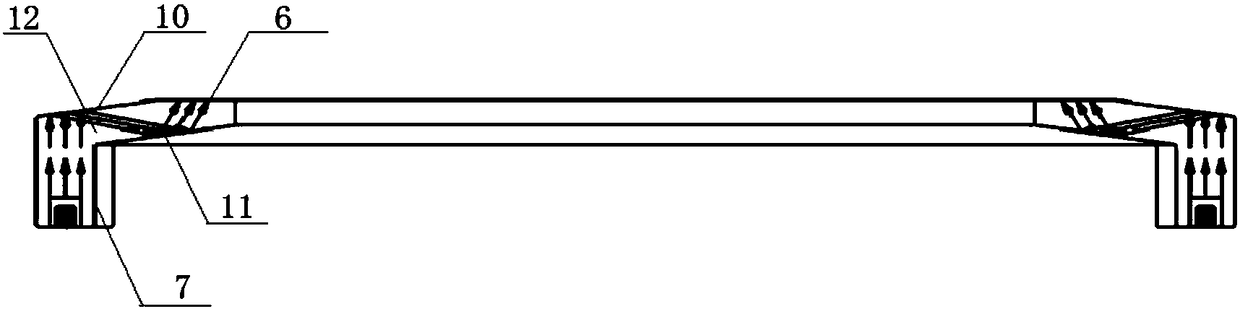

[0041] In this embodiment, the light guide part 12 includes a first reflective plate 10 and a second reflective plate 11 oppositely arranged for light reflection, so that the light from the LED lamp point 8 exits the light guide part 12 upwards relative to the horizontal plane;

[0042] Preferably, the section lines of the first reflective plate 10 and the second reflective plate 11 are arranged in parallel.

[0043] The light guide part 12 of the above-mentioned structure makes the light of the LED lamp point 8 irradiate upwards relative to the horizontal surface, which improves the utilization rate of the light. It is used to estimate the light irradiation range of the LED lamp, or adjust the structure of the light guide body 5 to change the light path of the light from the LED lamp point 8 .

Embodiment 2

[0045] In this embodiment, the upper side of the light guide part 12 is provided with a light-transmitting plate 6 for emitting light from the LED lamp point 8, and the two ends of the light-transmitting plate 6 are connected to the first reflector 10 and the second reflector 11 respectively. Phase-tight connection. Specifically, the transparent plate 6 is arranged horizontally.

[0046] The above arrangement makes the light guide body 5 in a sealed state, preventing dust from entering the light guide body 5 and affecting the reflection and divergence effect of the light guide body 5 on the light from the LED lamp spot 8 .

Embodiment 3

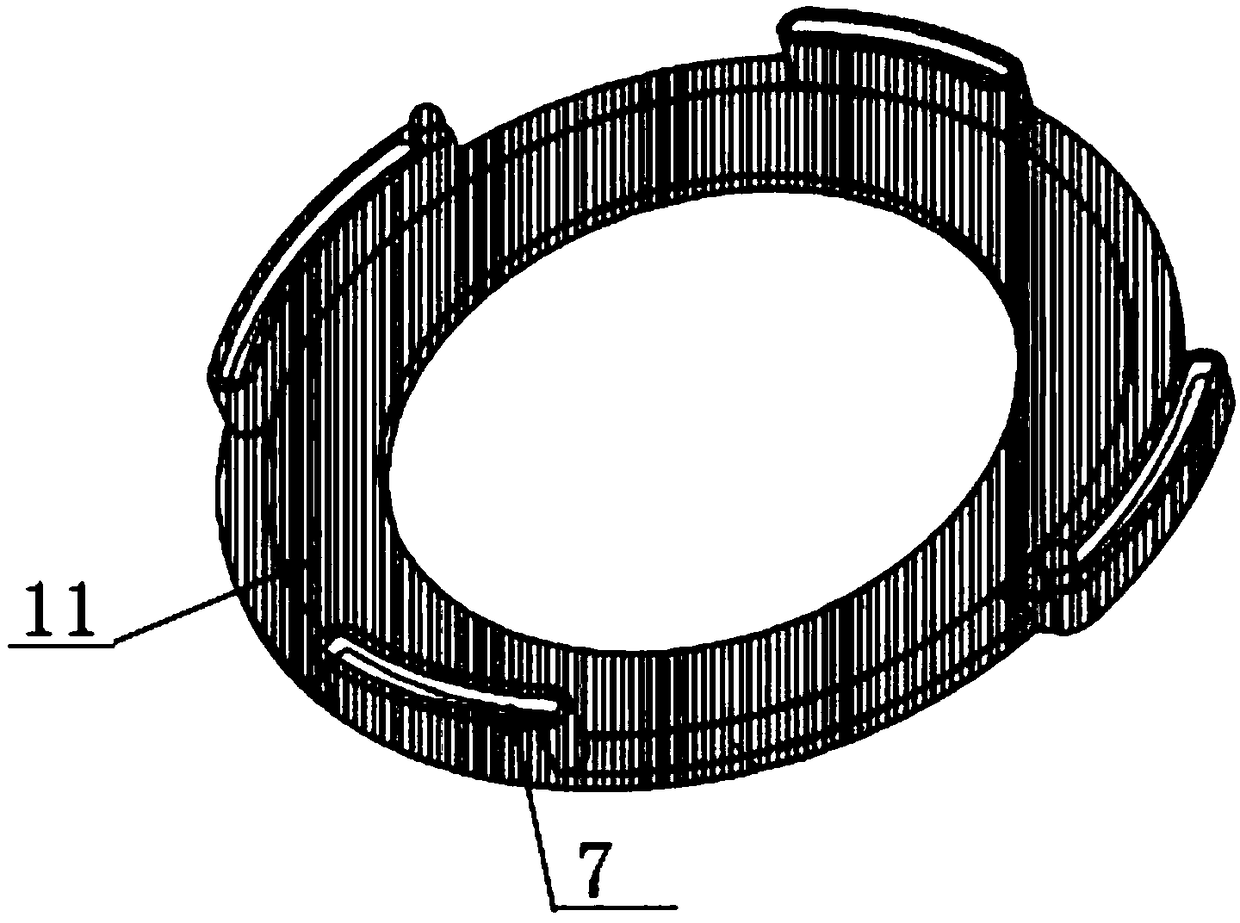

[0048] In this embodiment, the light guide body 5 is made of acrylic material. The light incident part 7 and the light guide part 12 are formed by spraying white paint to have a reflective effect. The paints used in the present invention are all high-gloss paints to enhance the reflection of light from the LED light spot 8 . The light-transmitting plate 6 is not sprayed with paint and is in a transparent state.

[0049] Acrylic has good light transmittance and is not brittle. Even if it is broken, it will not form sharp fragments, thus avoiding personnel scratch accidents caused by light guide body 5 being broken or broken after being broken. At the same time, it also has better Excellent high-temperature performance and processing performance, thereby ensuring that the light guide body 5 can be sleeved outside the heat-generating LED light point 8, and white paint can be sprayed on the light guide body 5 to improve light utilization and reflect light.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com