Method for predicting residual life of rolling bearings based on sparse coding

A technology of sparse coding and rolling bearings, which is applied to instruments, character and pattern recognition, computer components, etc., can solve problems such as loss of accuracy of prediction models, inability to make maintenance strategies, and deterioration of prediction results, so as to reduce the burden of prediction , Avoid sudden accidents and reduce economic losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

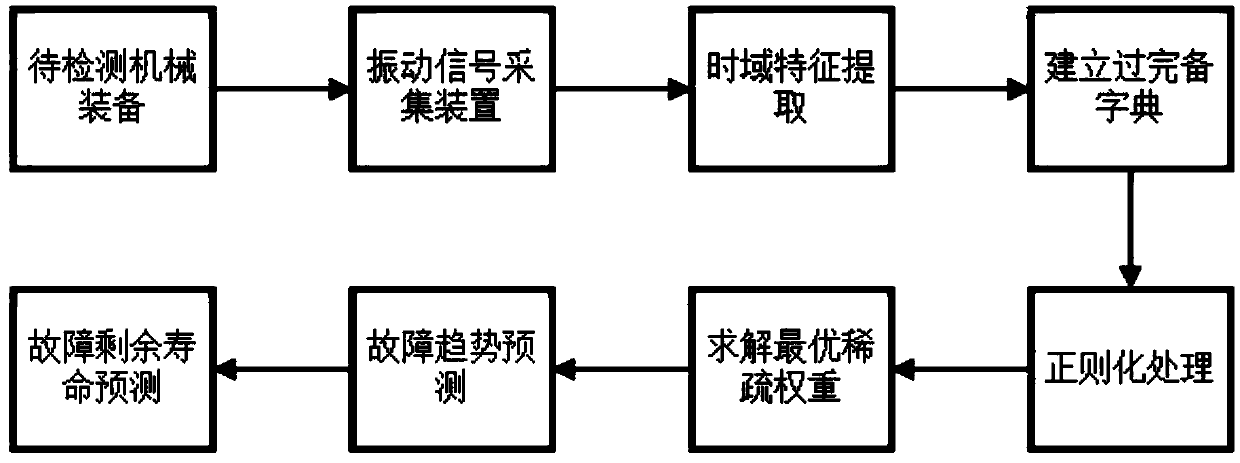

Method used

Image

Examples

Embodiment Construction

[0048] Below in conjunction with accompanying drawing, the content of specific embodiment of the present invention is described in further detail:

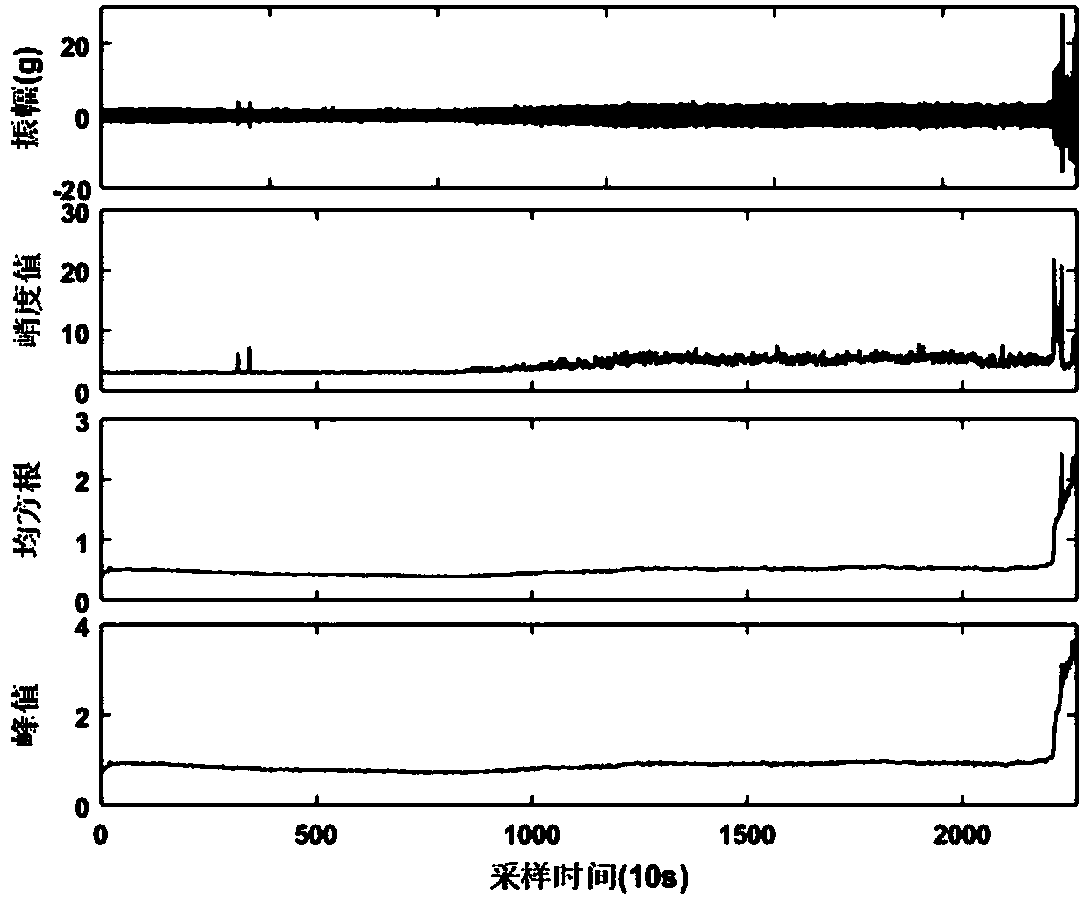

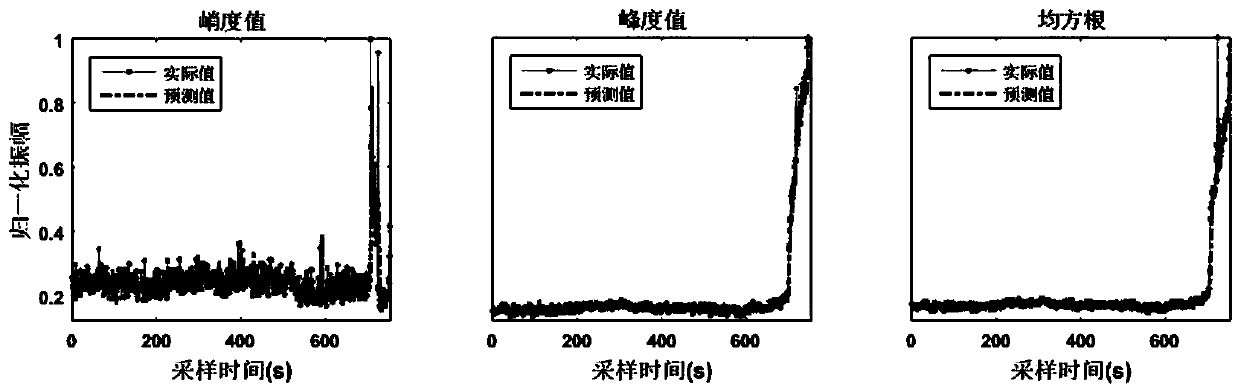

[0049] Rolling bearings are key components in mechanical equipment. However, rolling bearings may be damaged due to various reasons during operation, such as improper assembly, poor lubrication, moisture and foreign matter intrusion, corrosion and overload, etc. may cause premature damage to rolling bearings. Even if the installation, lubrication and maintenance are normal, after a period of operation, the rolling bearings will suffer from fatigue spalling, wear, pitting and other faults, which will cause the equipment to fail to work normally. The embodiment is to adopt the remaining life prediction model established by the present invention, analyze the vibration signals under two different working conditions, and obtain the remaining life prediction map.

[0050] The intelligent identification embodiment of the bearing vibratio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com