Automatic core closing mechanism for power battery

A power battery and cell technology, which is applied in the field of power battery automatic core closing mechanism, can solve the problems of unstable grasping force, uncontrollable force, damage to the pole ear, etc., so as to reduce labor costs, improve quality and production capacity, and reduce occupied space. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

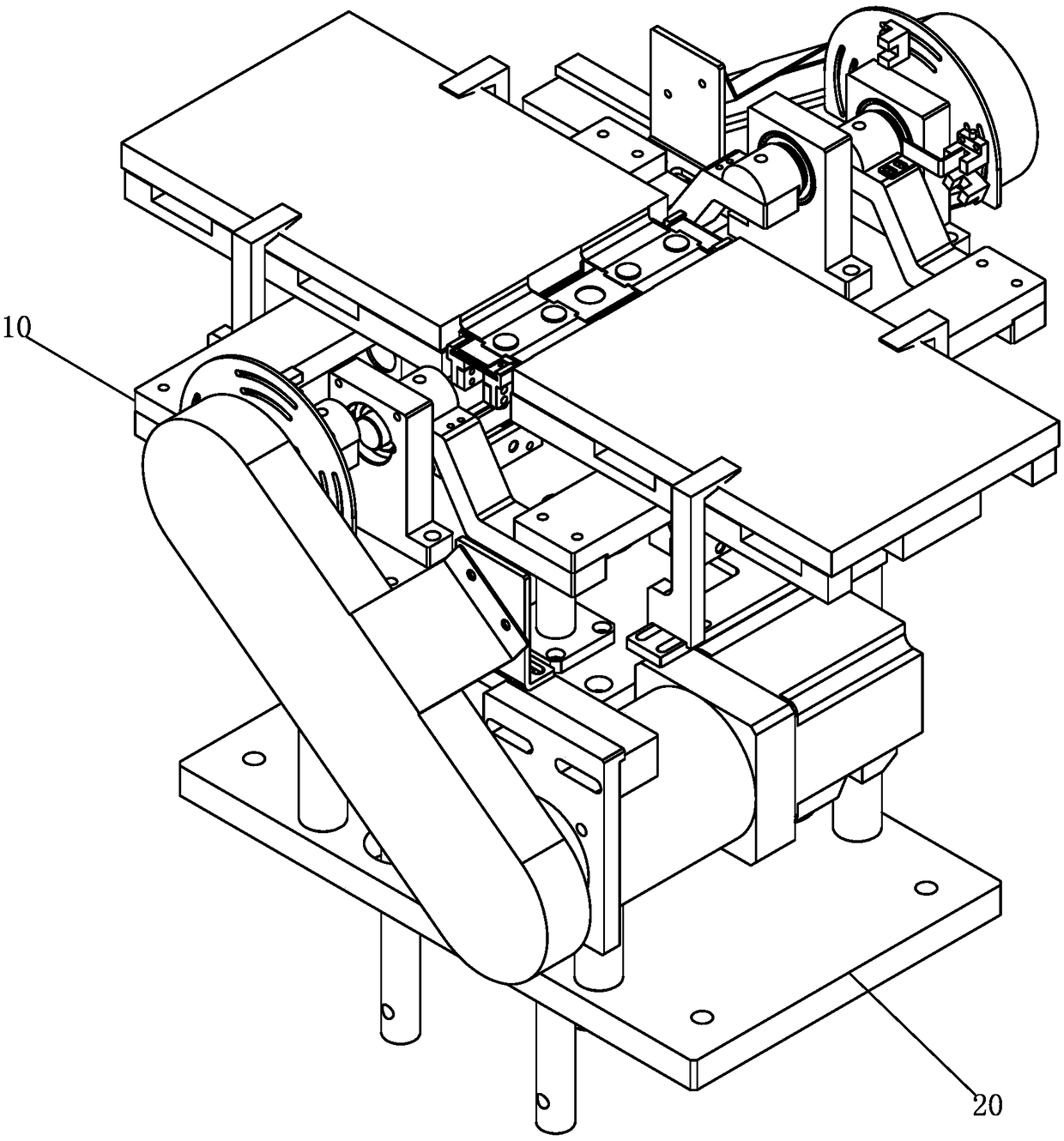

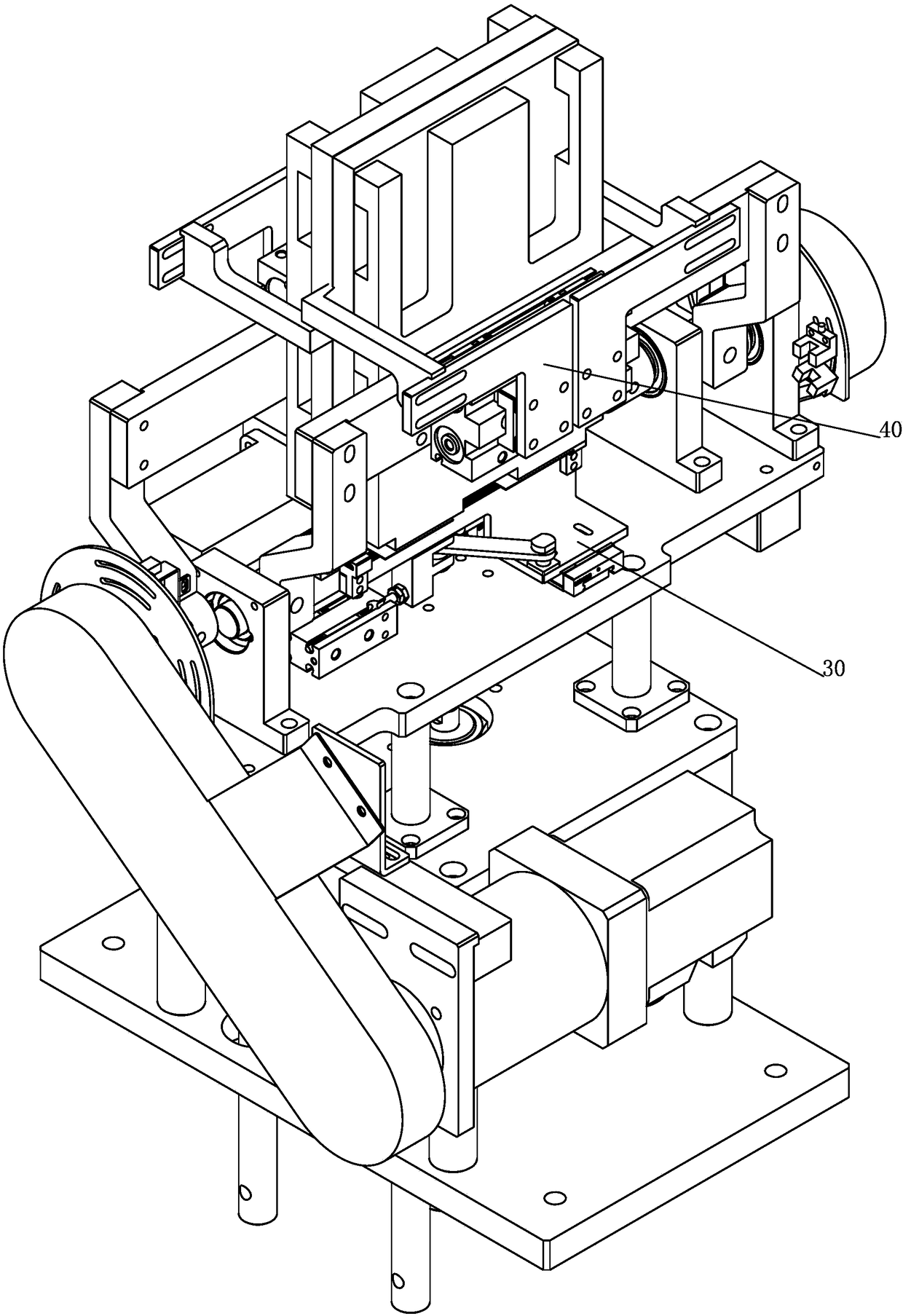

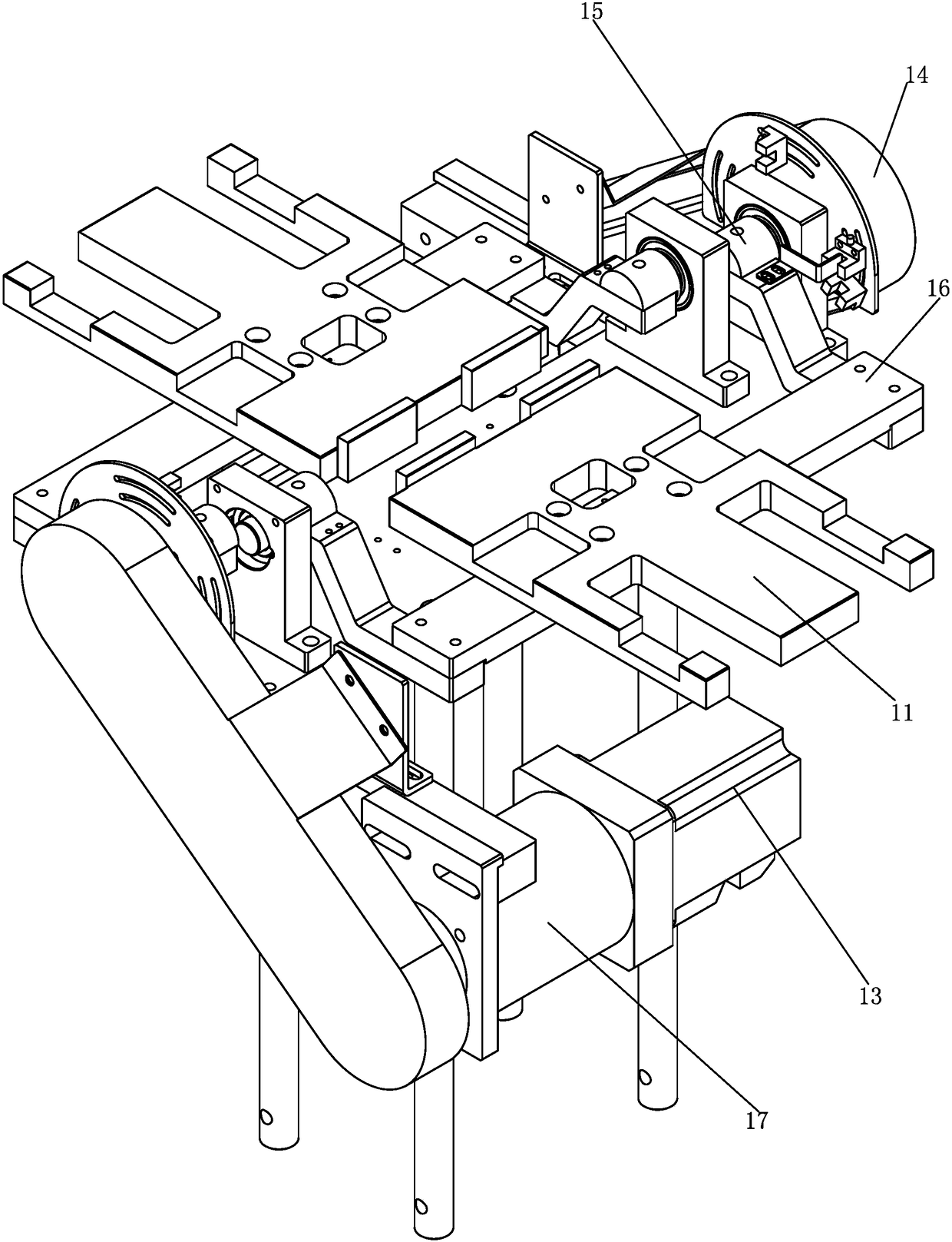

[0021] Such as Figure 1-6 As shown, an automatic core closing mechanism for a power battery includes a battery closing mechanism 10, a lifting base 20, a cover plate positioning and shaping mechanism 30, and a battery pressing mechanism 40. The battery closing mechanism 10 can be installed on a On the lifting base 20, the battery closing mechanism 10 includes two battery support plates 11 and a motor 13 for driving the opening and closing of the two core support plates. Two motors 13 are provided to drive the corresponding battery cores respectively. The supporting plate 11 is opened and closed, the cover plate positioning and shaping mechanism 30 is arranged between the two battery supporting plates 11, and the lower ends of the two battery supporting plates 11 are provided with a battery cell pressing mechanism 40, and the The cell pressing mechanism 40 includes a cell gripper 44 for fixing the position of the cell on the cell tray 11 .

[0022] Such as image 3 As shown,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com