Method of making agglomerated and thermally inhibited starch

A heat-inhibited, starch-based technology, applied in the field of heat-inhibited starch, viscosity modifier, can solve the problem of negligible viscosity improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

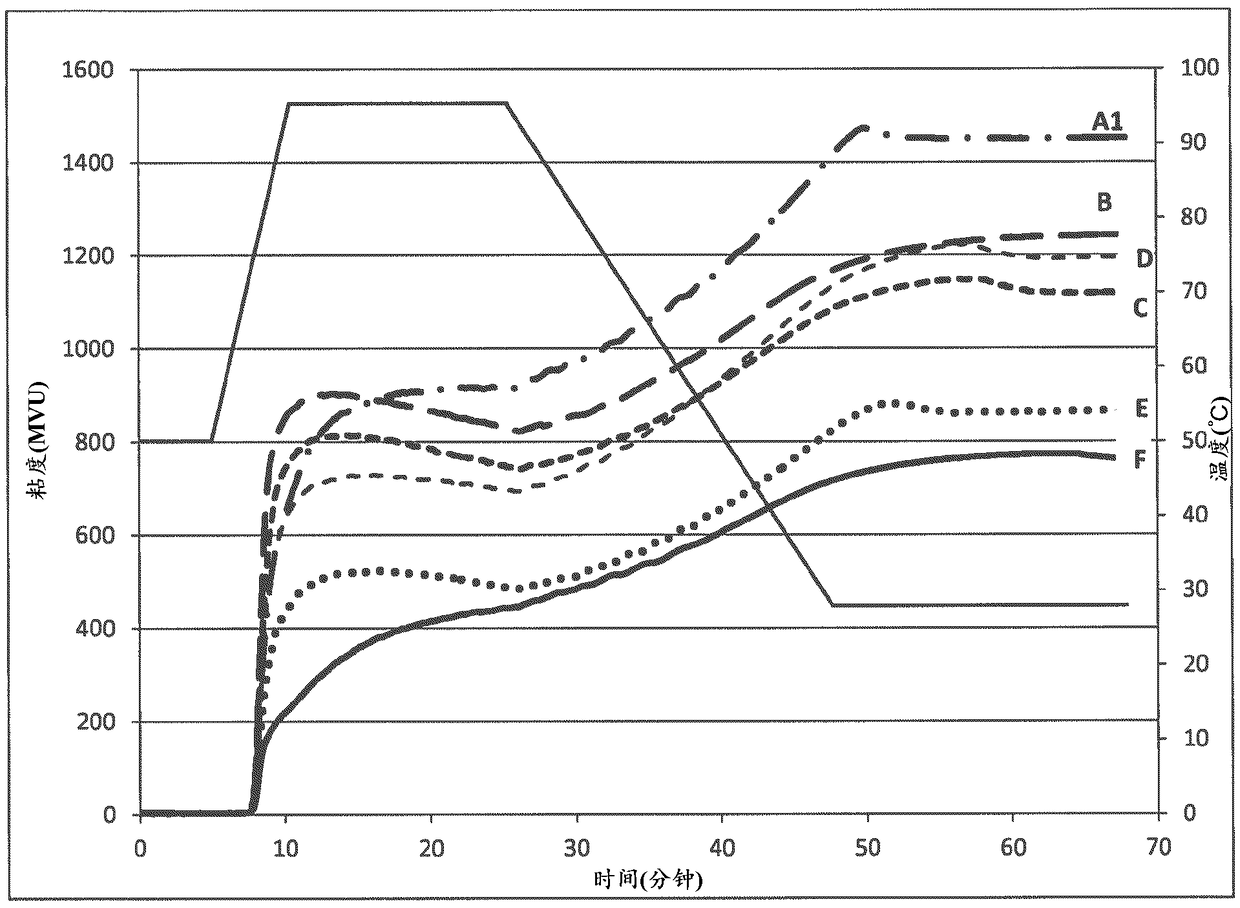

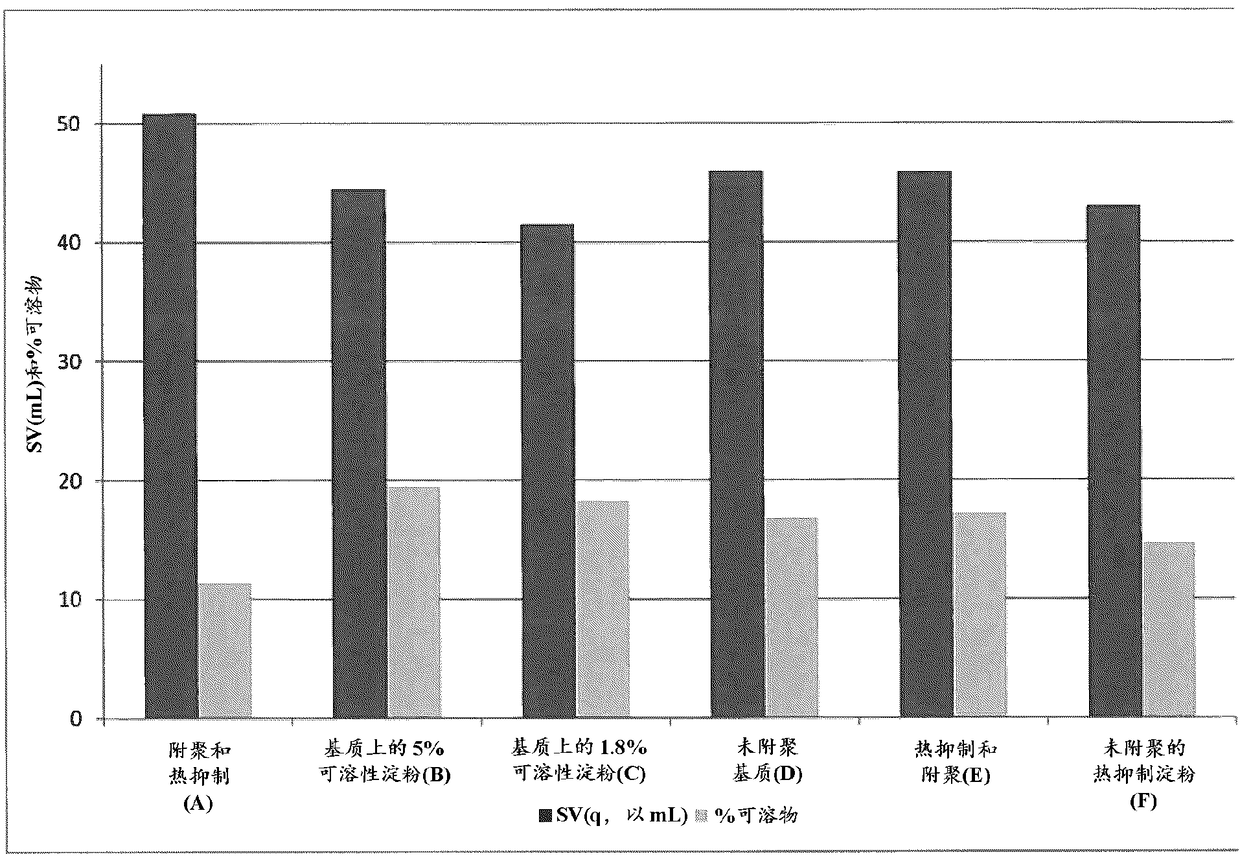

[0128] Embodiment 1-laboratory scale production

[0129] Starch samples with various levels of starch binder and various amounts of buffer in the starch granules were prepared according to the recipe in Table 1 below.

[0130] Table 1 - Sample Recipe and Process

[0131] sample

[0132] 1 The starch binder was a commercially available cold water-swellable starch derived from waxy corn (ULTRA-SPERSE®, starch from Ingredion Incorporated, Westchester, Illinois).

[0133] 2 The starch granules were waxy corn starch obtained from Ingredion Incorporated, Westchester, Illinois.

[0134] 3 Heat-inhibited starch granules of the comparative unagglomerated control.

[0135] Each sample was prepared based on the formulation and process provided in Table 1 to demonstrate their effect on viscosity and to compare heat-inhibited agglomerated starch with non-agglomerated heat-inhibited starch (ie, samples D and F). Samples were prepared as follows.

[0136] Sample Al was prepa...

Embodiment 2

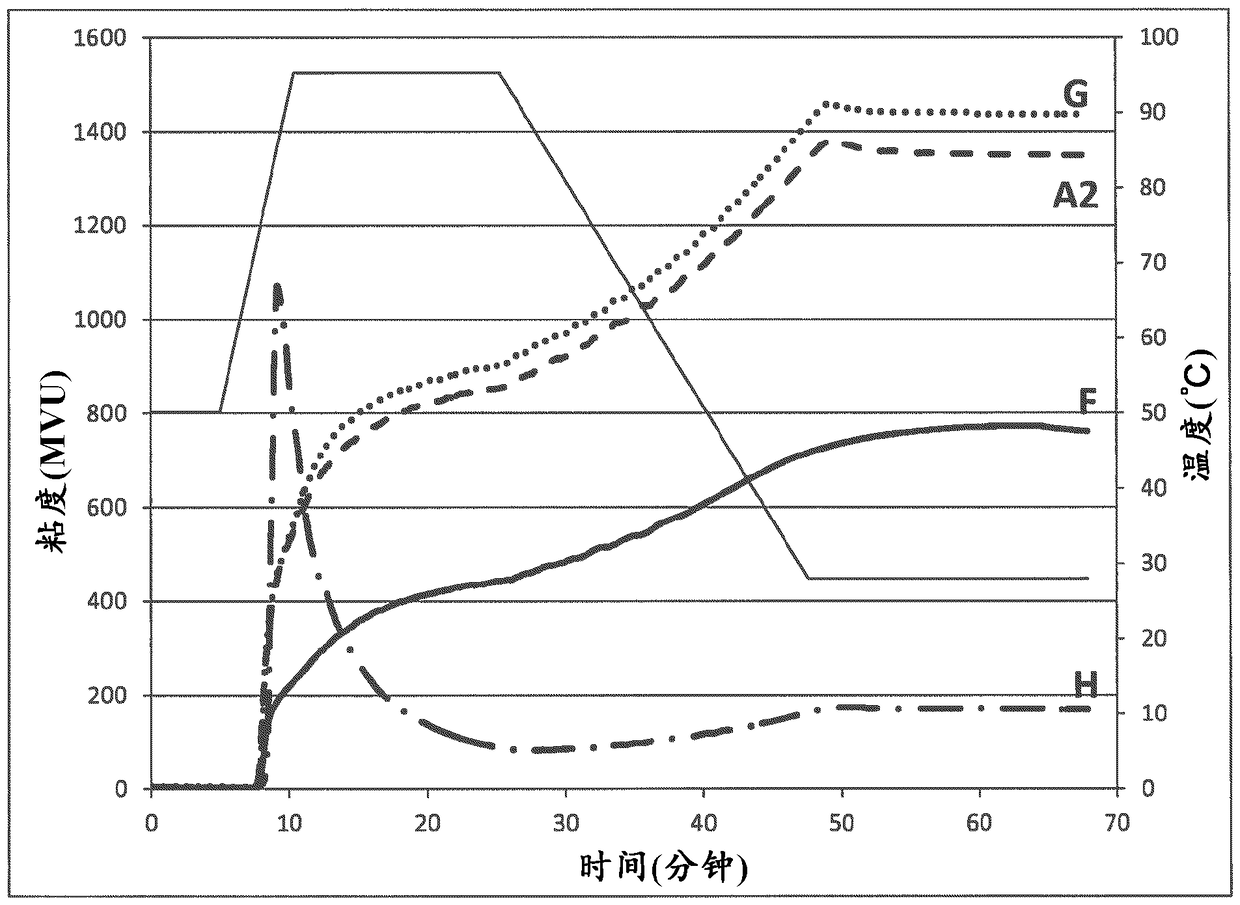

[0149] Example 2 - Pilot Scale Production

[0150] Starch samples with 5% starch binder (based on the weight of the starch granules) and various amounts of buffer in the starch binder or starch granules were prepared according to the recipe in Table 2 below.

[0151] Table 2 - Sample Recipe and Process

[0152] sample

starch binder 1 Amount (%w / w based on starch granules)

Amount of buffer in starch binder (% w / w based on starch granules)

starch granules 2 Amount of buffer in medium (%w / w based on starch granules)

Process / Remarks

A2

5.00

1.00

0.00

agglomerated, then thermally inhibited

F 3

0.00

0.00

N / A

business reference

G

5.00

0.00

2.00

agglomerated, then thermally inhibited

H 4

0.00

0.00

0.00

Starch Granules Reference

[0153] 1 The starch binder was a commercially available cold water-swellable starch derived from waxy corn (ULTRA-SPERSE®, starch from Ingredio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com