Multi-range integrated laser probe device and using method thereof

A laser measuring head and multi-range technology, which is applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problem of precise positioning of position sensitive components and the guarantee of repeated positioning accuracy is difficult to achieve, the measurement site and environment have high requirements, calibration Problems with the cumbersome calibration process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] The present invention will be further described below in conjunction with drawings and embodiments.

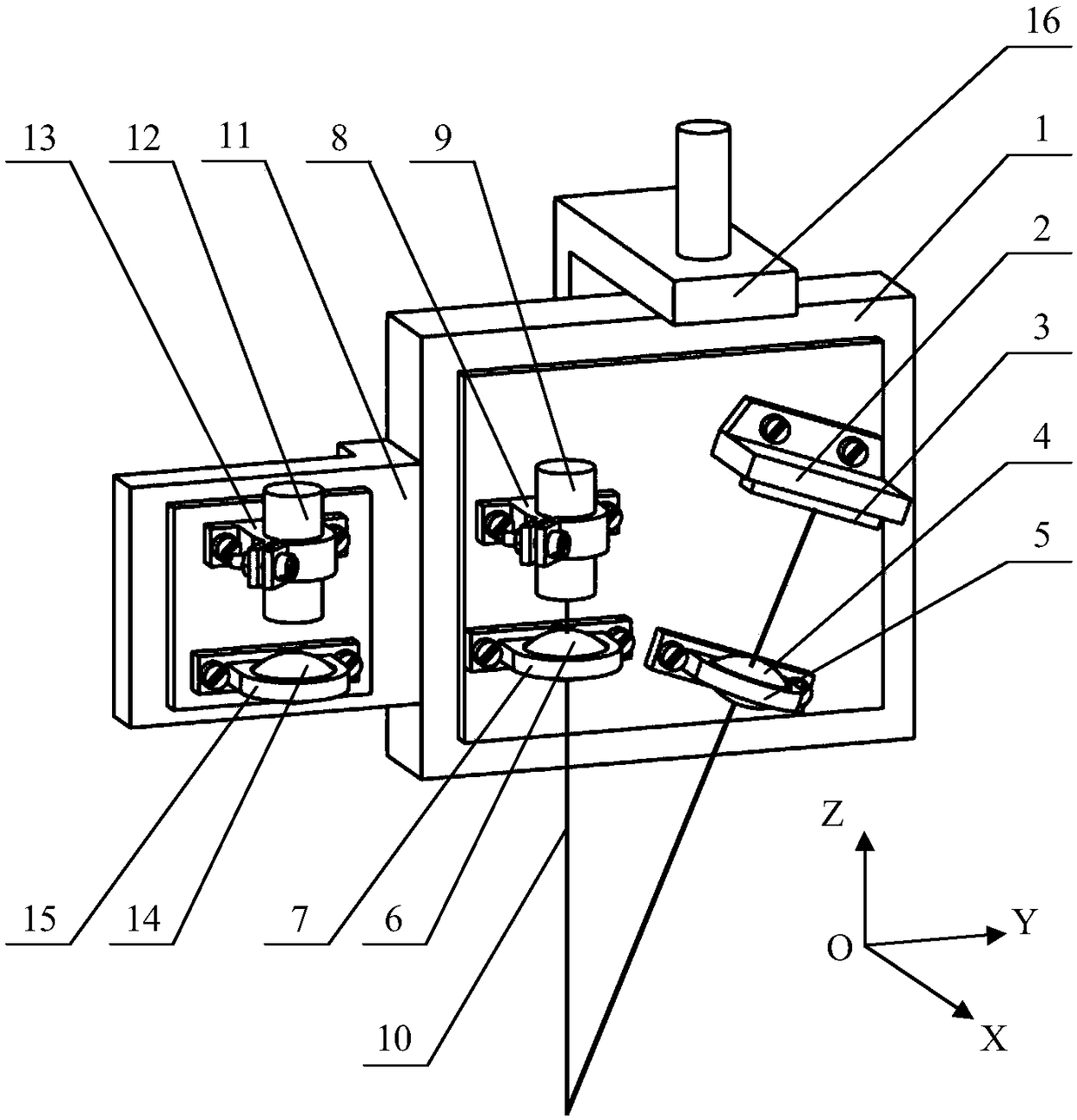

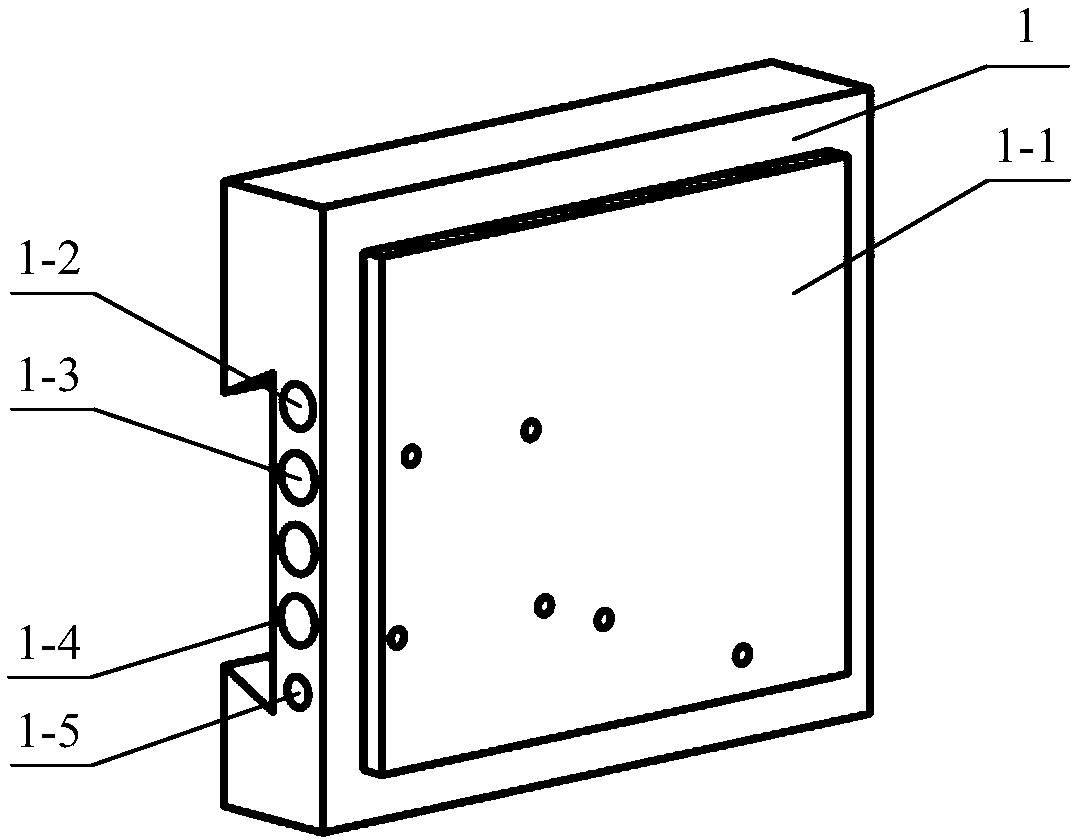

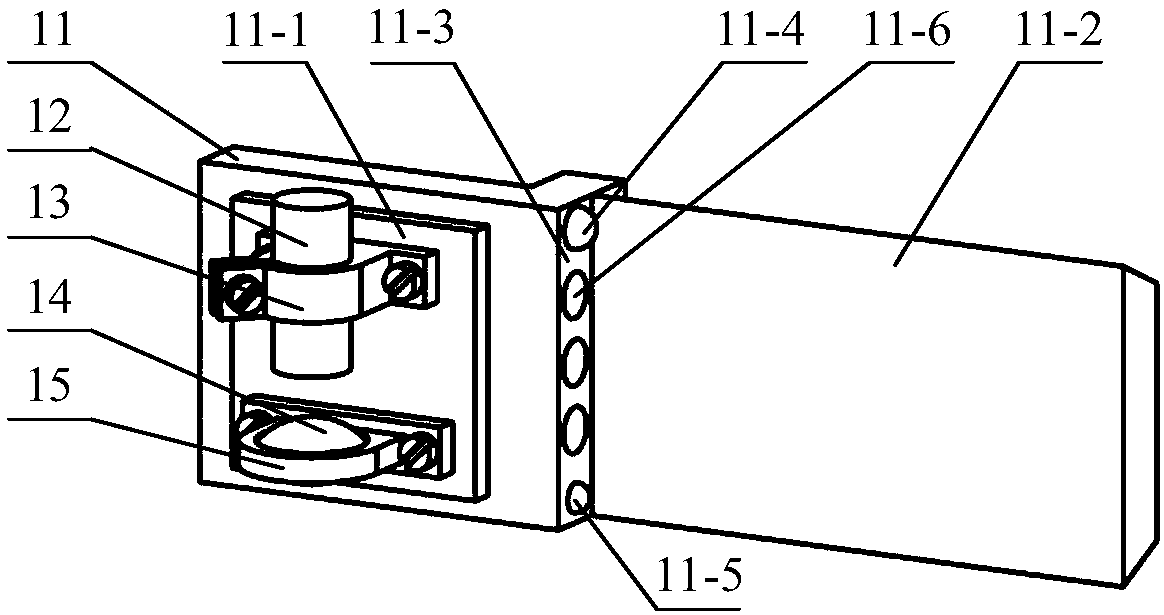

[0063] Such as figure 1 , 2 , 3, 4 and 5, a multi-range integrated laser probe device, including the first range main substrate 1, chip holder 2, position sensitive element 3, receiving lens 4, receiving lens holder 5, first focusing lens 6. The first lens holder 7, the first holder 8, the first laser 9, the second range plate 11, the second laser 12, the second holder 13, the second focusing lens 14, the second lens holder 15, positioning and installation Part 16, the third range board 17, the third laser 18, the third holder 19, the third focusing lens 20, the third lens holder 21, the fourth range board 22, the fourth laser 23, the fourth holder 24, the fourth Four focusing lenses 25 , a fourth lens holder 26 and a pressing bolt 27 .

[0064] Such as figure 1 with 2 As shown, the front of the first measuring range main substrate 1 is provided with an integrally ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com