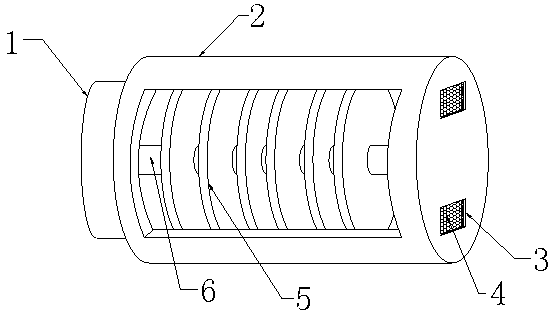

Industrial-grade spiral squeeze-out type air purification device

An air purification device and screw extrusion technology, which is applied in the direction of combination device, climate change adaptation, climate sustainability, etc., can solve the problems of incomplete air purification, inability to air pretreatment, poor purification effect, etc., and achieve novel structure, The effect of good processing and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

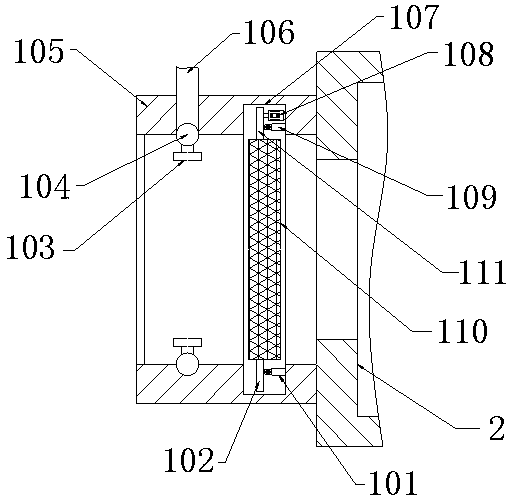

specific Embodiment approach

[0020] Specific implementation method: when in use, run the drive motor, the drive motor drives the drive shaft 6 to rotate, the drive shaft 6 rotates to drive the spiral blade 5 to rotate, and then the air enters the processing cylinder 105, then runs the external water delivery equipment, and the external water delivery equipment transfers the water flow Delivered to the water pipe 106, the water pipe 106 conveys the water flow to the annular water pipe 104, and the annular water pipe 104 conveys the water flow to the atomizing nozzle 103, and the atomizing nozzle 103 sprays the water flow in the form of water mist, and the solid particles in the air are combined with the water mist , when the air passes through the filter screen 110, the filter screen 110 will absorb the solid particles, and then the operator runs the small vibration motor 108, and the small vibration motor 108 transmits the vibration to the upper connecting plate 111, and then the upper connecting plate 111 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com