VOCS waste gas collecting and detecting device and using method thereof

A technology of exhaust gas collection and detection device, which is applied in measurement devices, sampling devices, sampling and other directions, can solve the problems of unfavorable activated carbon adsorption plate utilization efficiency, poor absorption uniformity, and poor absorption performance of intake pipes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

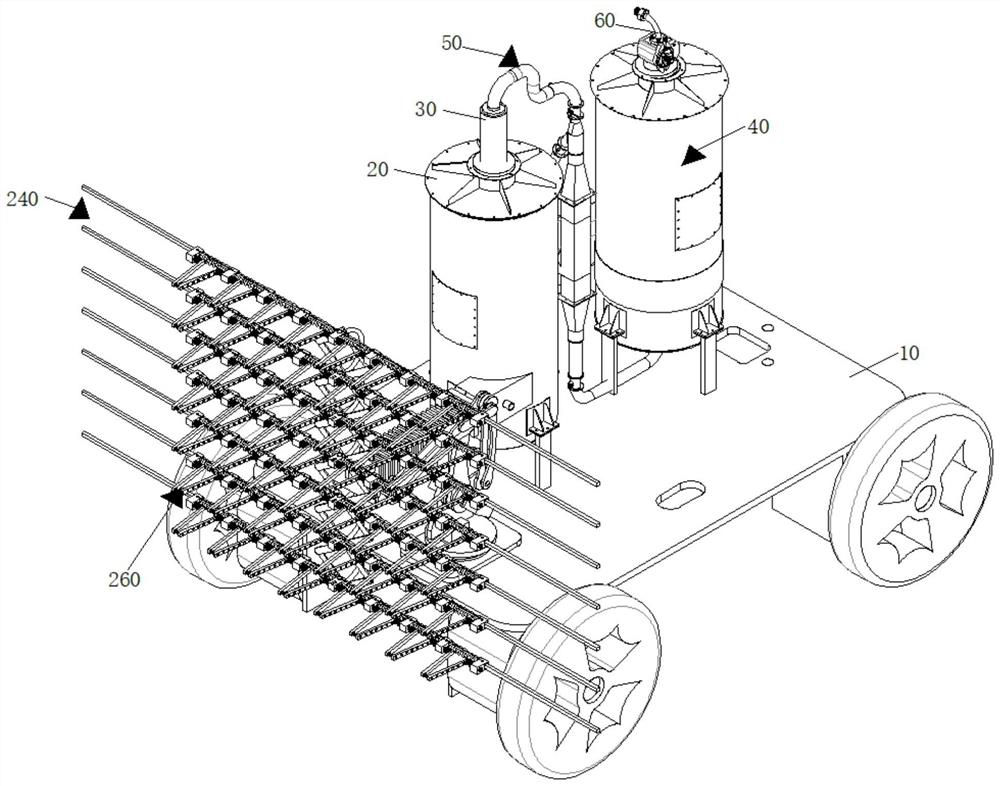

[0050] refer to Figure 1-6 , a VOCS exhaust gas collection detection device, including a movable base 10, also includes,

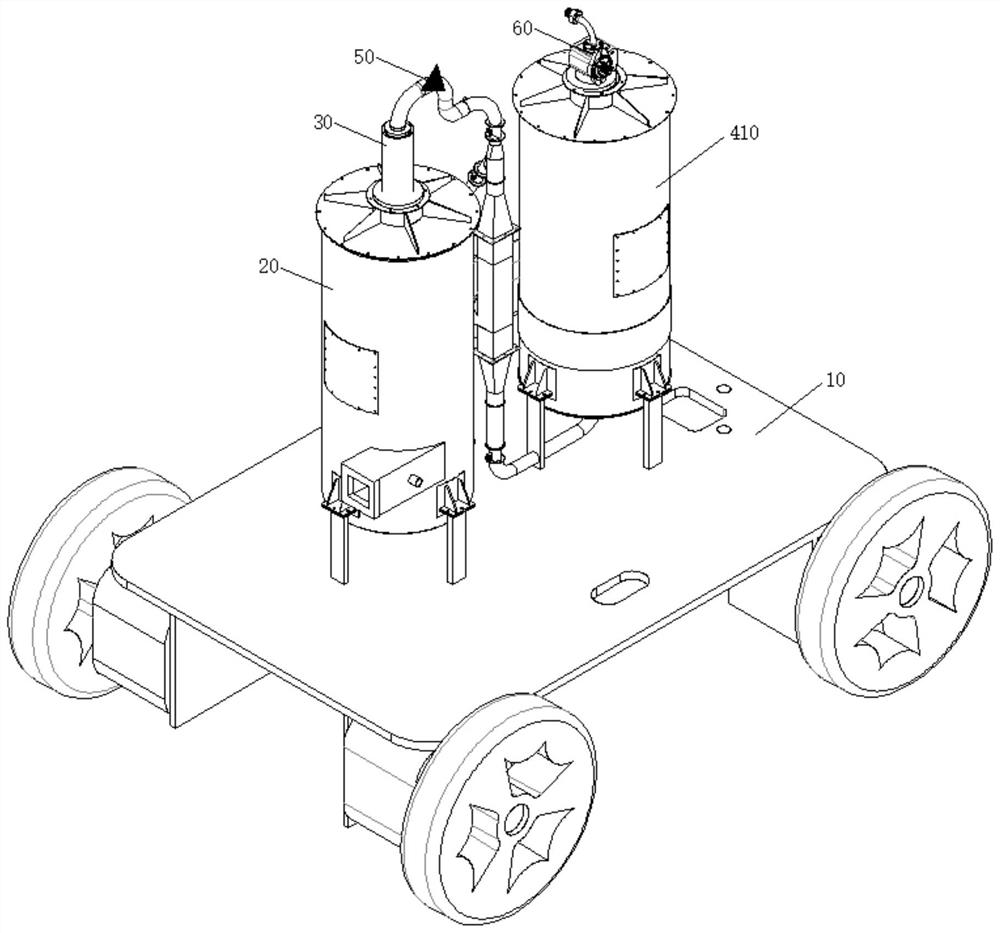

[0051] Washing tower 20, the washing tower 20 is installed on the top of the movable base 10, and has a waste gas inlet for washing VOCs waste gas;

[0052] Drying filter cartridge 30 is installed at the gas outlet of washing tower 20;

[0053] The adsorption tower 40 is installed on the top of the movable base 10 for adsorbing VOCs waste gas;

[0054] The detection unit 50 is connected between the outlet end of the drying filter cartridge 30 and the inlet end of the adsorption tower 40 for detecting VOCs exhaust gas;

[0055] The negative pressure discharge unit is installed at the gas outlet of the adsorption tower 40;

[0056] in,

[0057] The inlet end of the washing tower 20 is connected with a main waste gas inlet pipe 210, and the end of the main waste gas inlet pipe 210 away from the washing tower 20 is connected with a vertical first dispersi...

Embodiment 2

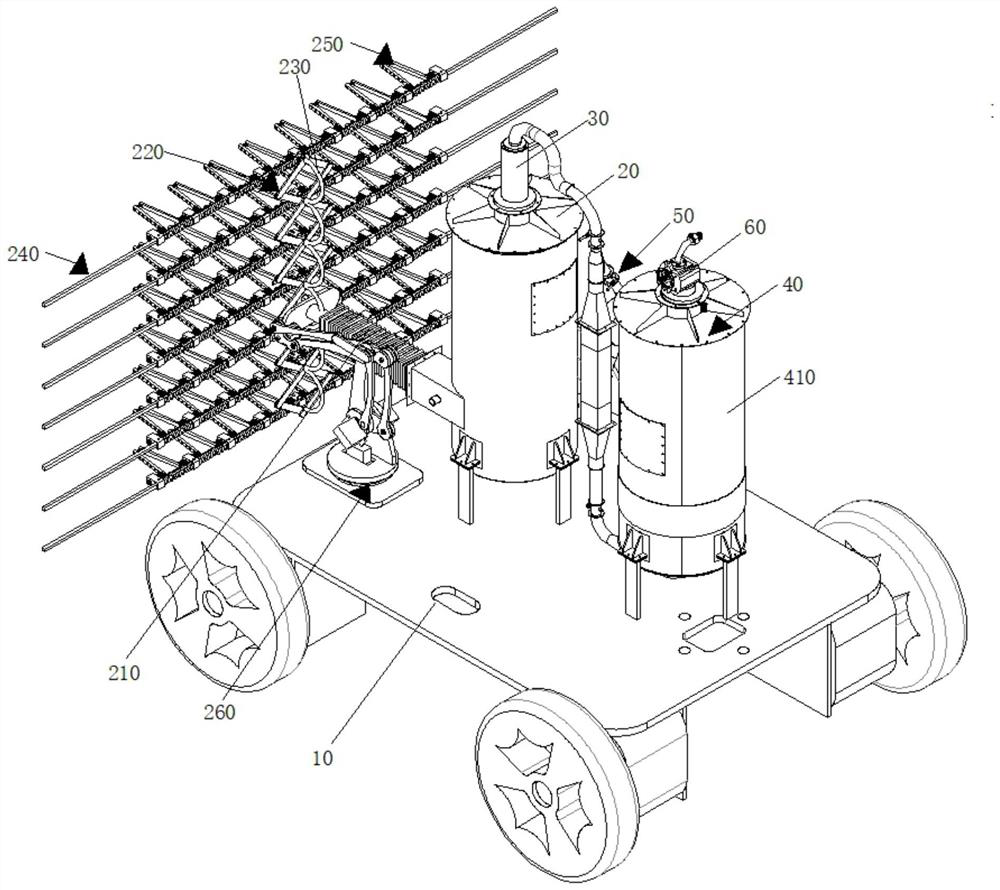

[0064] refer to Figure 5-8 , a VOCS exhaust gas collection and detection device, which is basically the same as Embodiment 1. Furthermore, the first dispersion mechanism 220 includes a mounting seat 221 installed at the junction of the main exhaust gas inlet pipe 210 and the secondary exhaust gas inlet pipe 230, and is slidably arranged on the The first screw base 222 and the second screw base 223 of the mounting part of the mounting base 221, the driving screw 224 that is threadedly engaged with the first screw base 222 and the second screw base 223 installed on the mounting part of the mounting base 221 and The scissor link set 225 installed vertically on the first screw base 222 and the second screw base 223 , the air inlets of the secondary exhaust gas inlet pipe 230 are evenly distributed at the hinge points of the scissor link set 225 .

[0065] refer to Figure 5-8 The exhaust gas collection branch pipe 250 includes straight pipe collection sections 251 and hose insta...

Embodiment 3

[0069] refer to Figure 5 , a VOCS exhaust gas collection and detection device, which is basically the same as that of Embodiment 2, furthermore, the top of the movable base 10 is also connected with a universal adjustment arm 260, and the adjustment section of the universal adjustment arm 260 is fixed to the mounting seat 221 When in use, move the device to the waste gas generation point through the movable base 10, adjust the angle of the collection point through the universal adjustment arm 260, and then realize the applicable performance of multi-angle collection. At the same time, turn on the negative pressure pump 60 to realize the main waste gas Inlet pipe 210 has the function of absorbing exhaust gas.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com