Cutting fluid recycling mechanism for machine tool

A cutting fluid and machine tool technology, applied in the field of machine tool cutting fluid recycling mechanism, can solve the problems of debris accumulation, affecting electromagnet recovery, uneven dispersion performance, etc., to improve uniformity, reduce metal debris content, and reduce clogging The effect of probability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

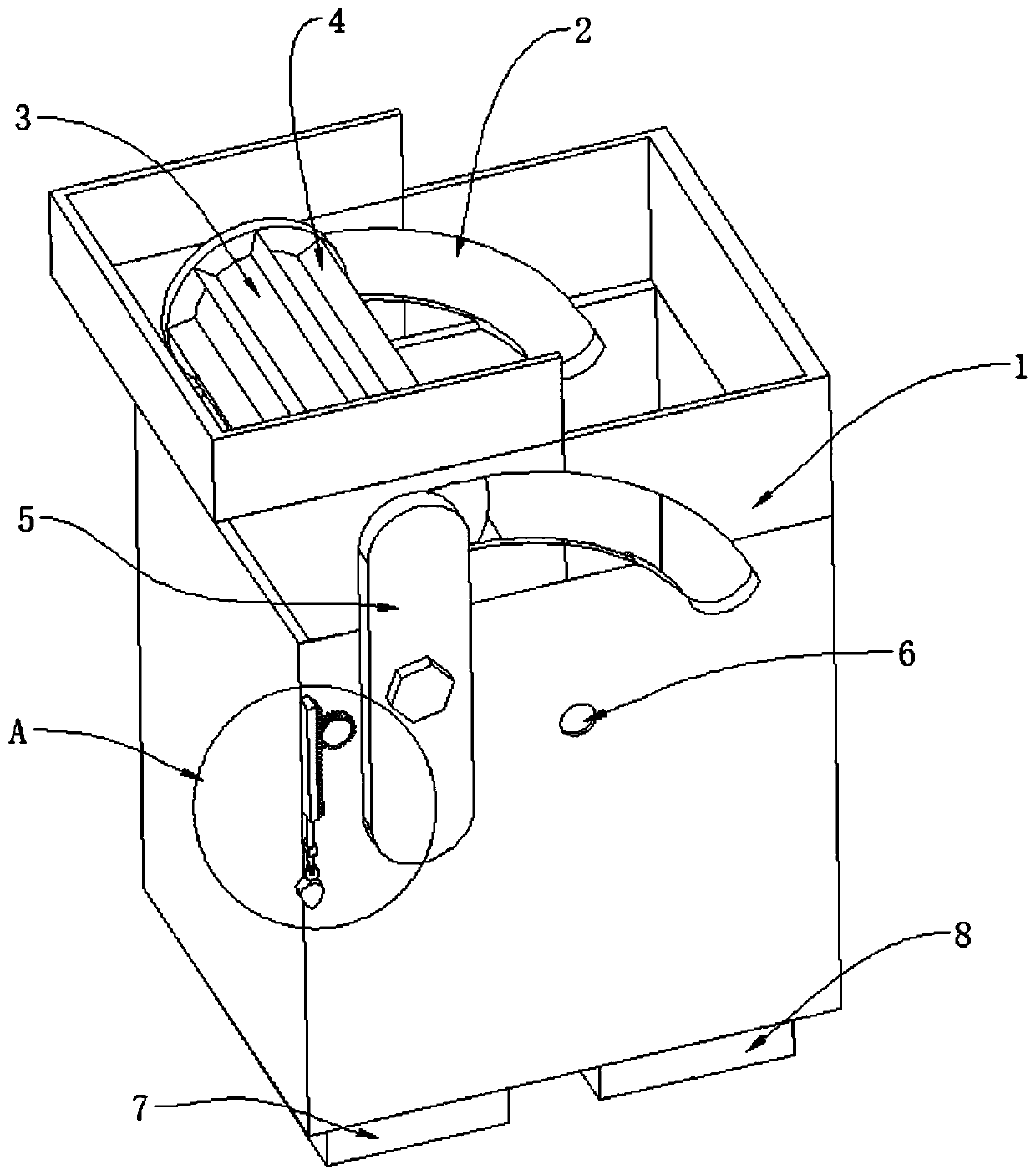

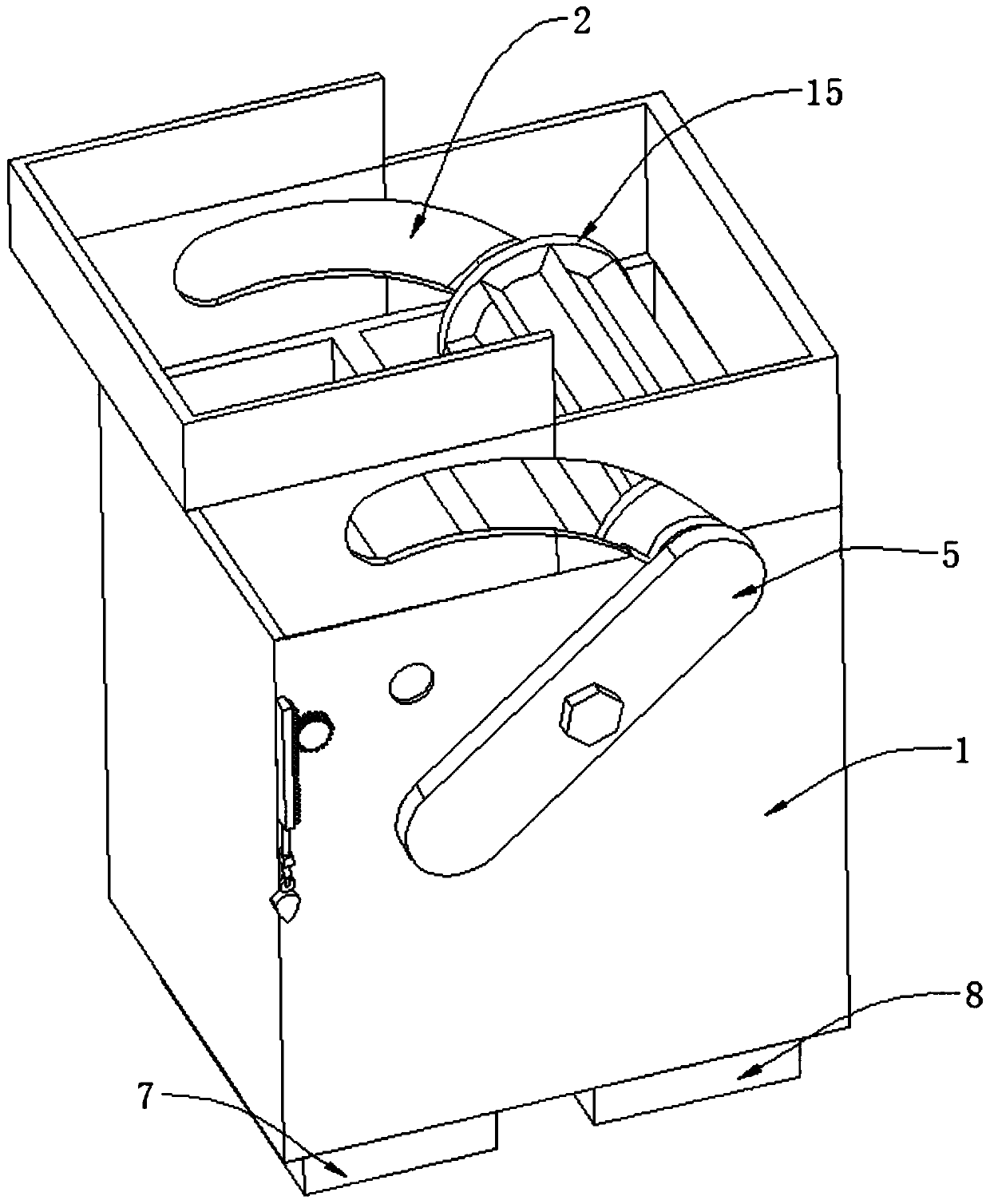

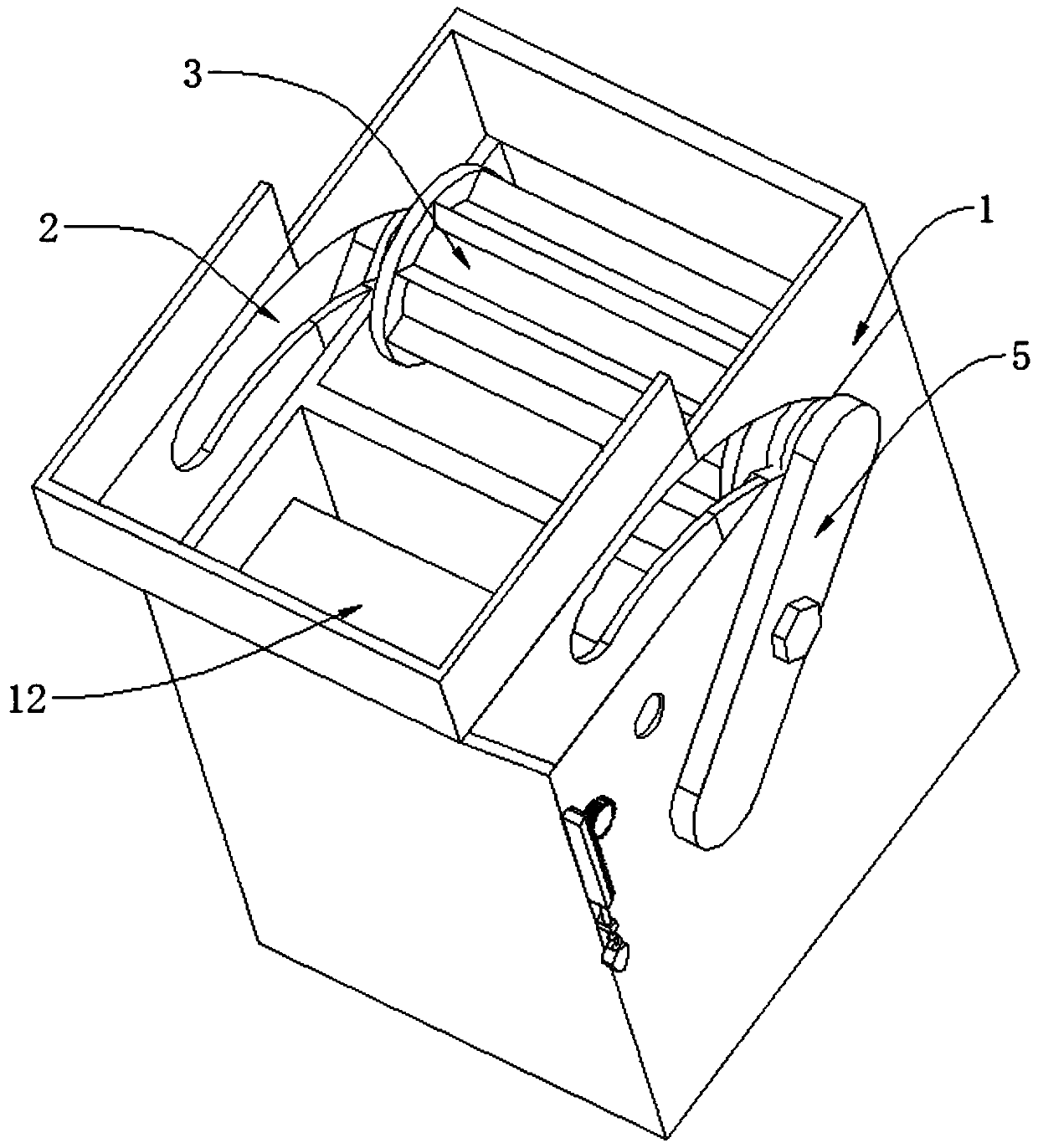

[0040] Such as Figure 1 to Figure 6 The cutting fluid recycling mechanism for machine tools shown includes a box body 1 with an open top, and also includes

[0041] The partition 14 is connected to the inner side wall of the box body 1, and separates the box body 1 into a waste liquid chamber and a waste debris chamber, and the partition 14 is provided with slots;

[0042] The adjustment groove 2 is set on the outer wall of the box body 1;

[0043] The adjusting plate 5 is rotatably connected to the outer wall of the box body 1;

[0044] The installation hole 6 is opened on the outer wall of the box body 1;

[0045] The drive roller 3 is connected between the adjustment plates 5 by being placed in the adjustment groove 2 and rotated;

[0046] The electromagnet adsorption plate 4 is evenly arranged on the outer side wall of the driving roller 3;

[0047] The blanking plate 12 is rotatably connected to the inner side wall of the box body 1 through a rotating shaft, and plac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com