Mixer for slow-release rare earth fertilizer

A technology of mixing machine and rare earth, which is applied in mixers, shaker/oscillation/vibration mixers, mixers with rotary stirring devices, etc., which can solve the problems of sticking to the wall and inability to improve the mixing rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

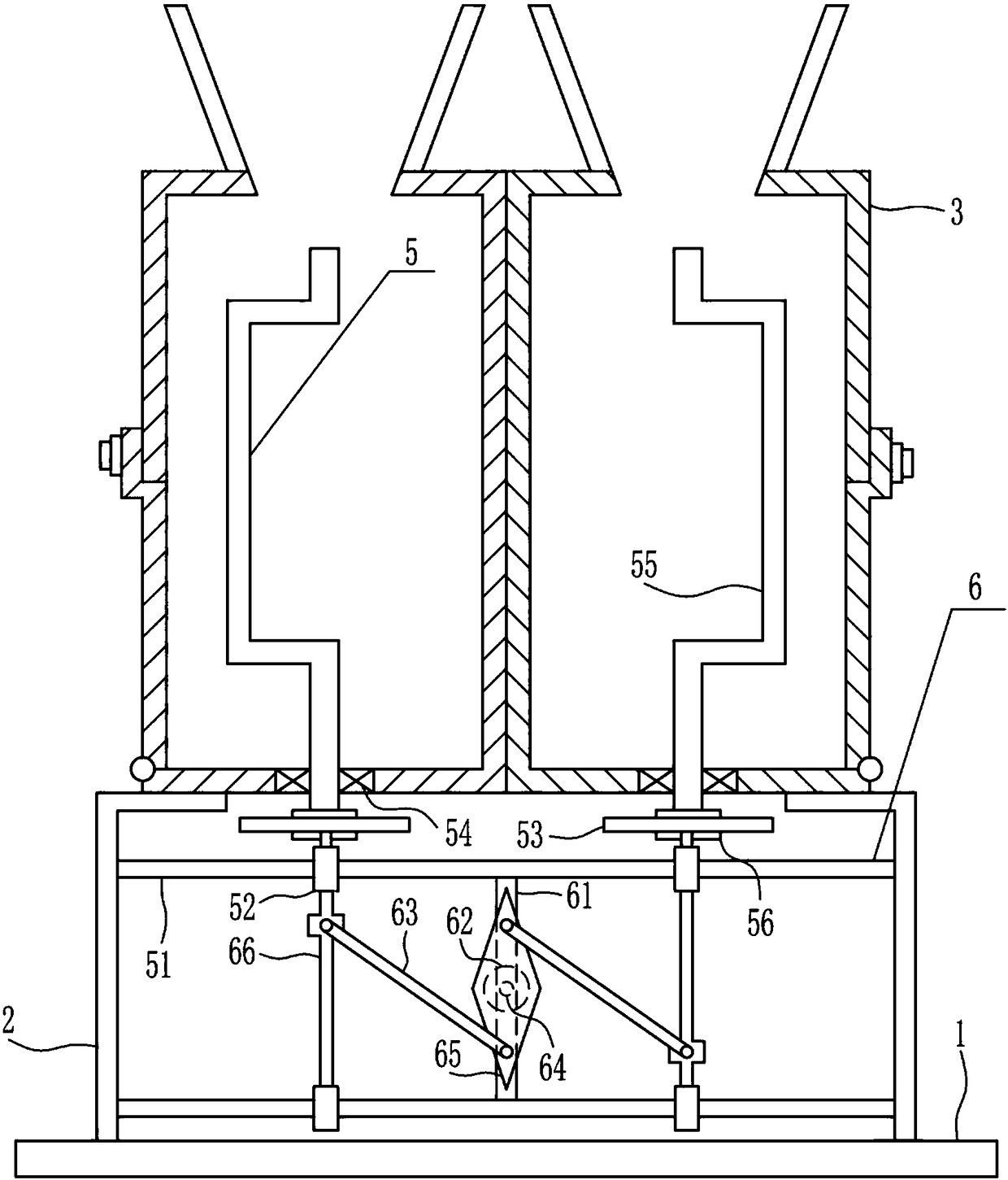

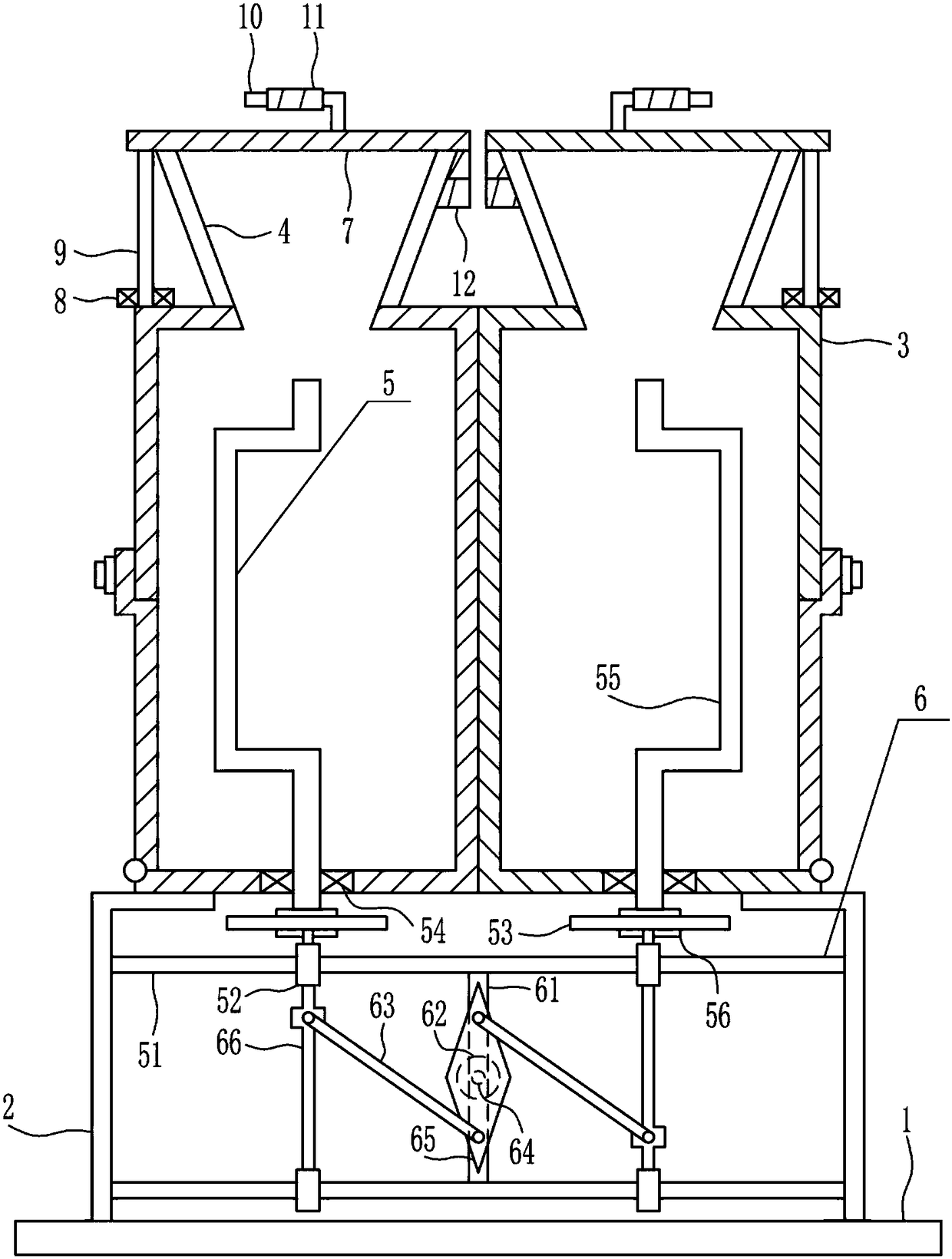

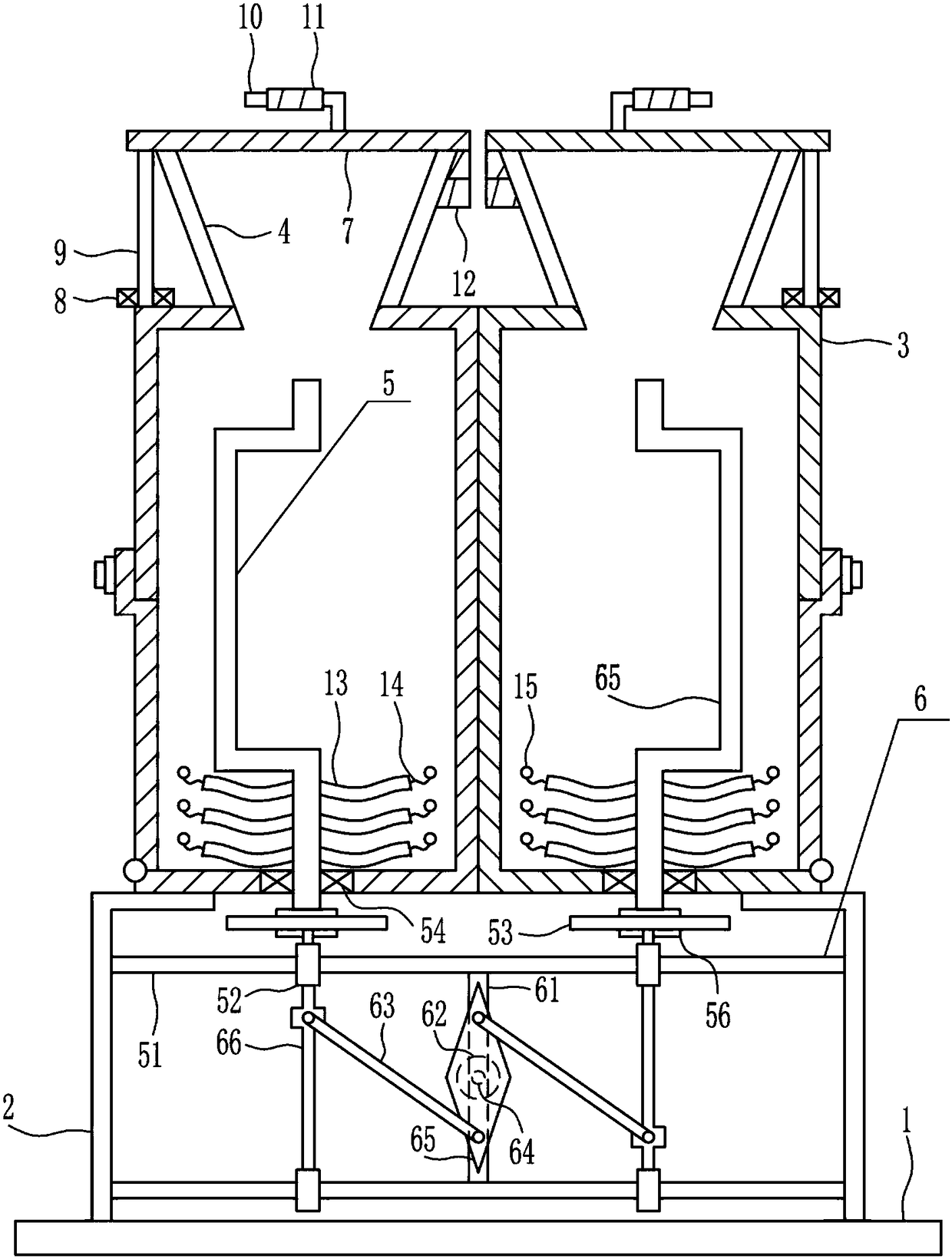

[0029] A slow-release rare earth fertilizer mixer, such as Figure 1-4 As shown, it includes a base 1, a first installation rod 2, a mixing box 3, a funnel 4, a mixing mechanism 5 and a driving mechanism 6. The top of the base 1 is symmetrically connected with the first installation rod 2, and the top of the first installation rod 2 The mixing box 3 is evenly connected, the inner side of the mixing box 3 on the left and right sides is connected, the funnel 4 is connected in the middle of the top wall of the mixing box 3, and the driving mechanism 6 is connected between the first installation rods 2 on the left and right sides , the driving mechanism 6 is connected with a mixing mechanism 5 .

Embodiment 2

[0031] A slow-release rare earth fertilizer mixer, such as Figure 1-4 As shown, it includes a base 1, a first installation rod 2, a mixing box 3, a funnel 4, a mixing mechanism 5 and a driving mechanism 6. The top of the base 1 is symmetrically connected with the first installation rod 2, and the top of the first installation rod 2 The mixing box 3 is evenly connected, the inner side of the mixing box 3 on the left and right sides is connected, the funnel 4 is connected in the middle of the top wall of the mixing box 3, and the driving mechanism 6 is connected between the first installation rods 2 on the left and right sides , the driving mechanism 6 is connected with a mixing mechanism 5 .

[0032]The mixing mechanism 5 includes a guide rail 51, a sliding sleeve 52, a rack 53, a first bearing seat 54, a second rotating rod 55 and a gear 56, and a guide rail 51 is symmetrically connected up and down between the first installation rods 2 on the left and right sides, The slidi...

Embodiment 3

[0034] A slow-release rare earth fertilizer mixer, such as Figure 1-4 As shown, it includes a base 1, a first installation rod 2, a mixing box 3, a funnel 4, a mixing mechanism 5 and a driving mechanism 6. The top of the base 1 is symmetrically connected with the first installation rod 2, and the top of the first installation rod 2 The mixing box 3 is evenly connected, the inner side of the mixing box 3 on the left and right sides is connected, the funnel 4 is connected in the middle of the top wall of the mixing box 3, and the driving mechanism 6 is connected between the first installation rods 2 on the left and right sides , the driving mechanism 6 is connected with a mixing mechanism 5 .

[0035] The mixing mechanism 5 includes a guide rail 51, a sliding sleeve 52, a rack 53, a first bearing seat 54, a second rotating rod 55 and a gear 56, and a guide rail 51 is symmetrically connected up and down between the first installation rods 2 on the left and right sides, The slid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com