Membrane extraction tank with movable separation boards

A technology of movable partitions and extraction tanks, applied in solvent extraction, chemical instruments and methods, separation methods, etc., can solve problems affecting extraction effects, restricting film quality, immersion, etc., to improve film quality, increase reaction time, Improves the effect of extraction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

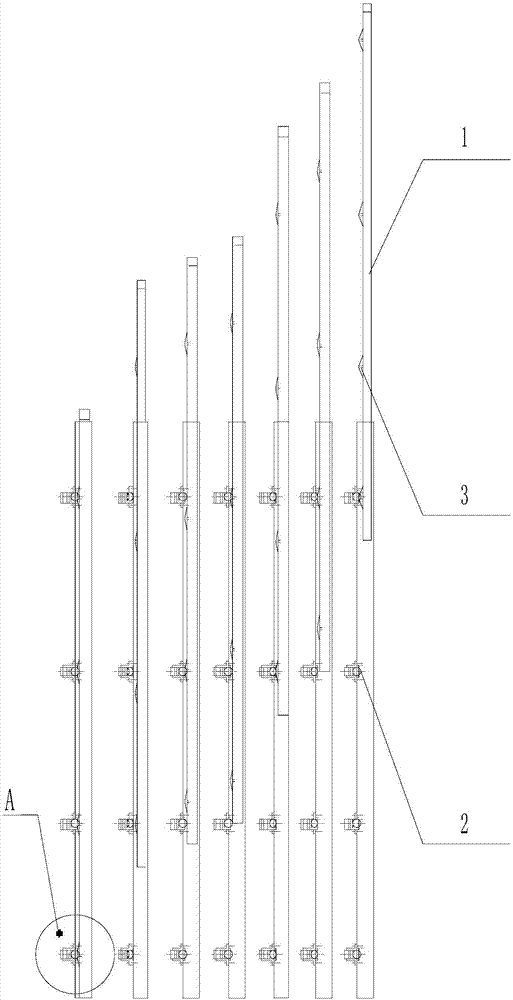

[0017] Such as figure 1 As shown, the movable partition 1 is installed in the guide groove 2, and can be installed or disassembled according to production needs, preferably more than 3, and the movable partition 1 is provided with four bosses 3; The four jacking devices corresponding to the platform 3, when the movable partition 1 all enters the guide groove 2 in the groove, the jacking device will completely withstand the four bosses 3 on the movable partition 1 .

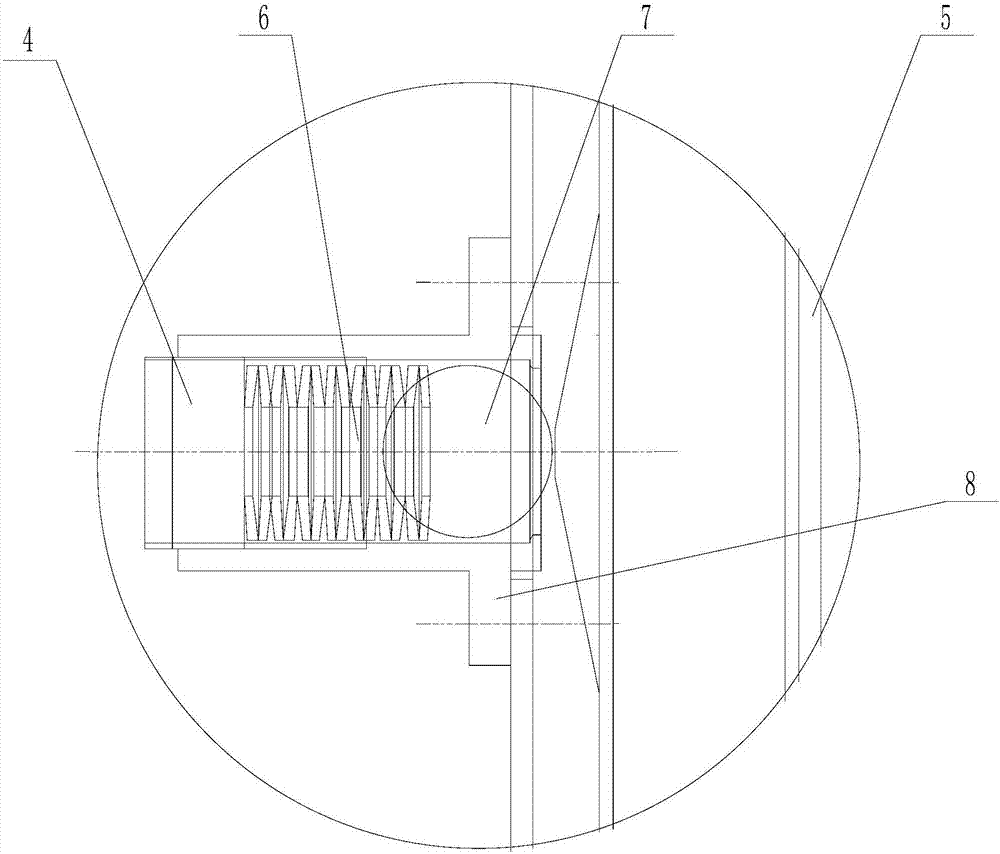

[0018] Such as figure 2 As shown, the tightening device includes a seat body 8, an adjusting nut 4, a tightening spring 6 and a sphere 7, the sphere 7 is connected with the boss 3 of the movable partition 1, the other end of the sphere 7 is connected with a tightening spring 6, and the tightening The spring 6 is connected with the adjusting nut 4, the adjusting nut 4 is fixed on the seat body 8, the seat body 8 is arranged on the guide groove, and a sealing layer 5 is provided on one side of the movable partitio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com