Preparation method of anti-aging agent for butadiene-nitrile rubber

A technology of nitrile rubber and anti-aging agent, which is applied in the field of rubber additive preparation, which can solve the problems of reducing the service life of nitrile rubber, becoming hard and brittle, and destroying the elastic structure of rubber, so as to achieve less environmental pollution and good anti-aging effect , the effect of improving economic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

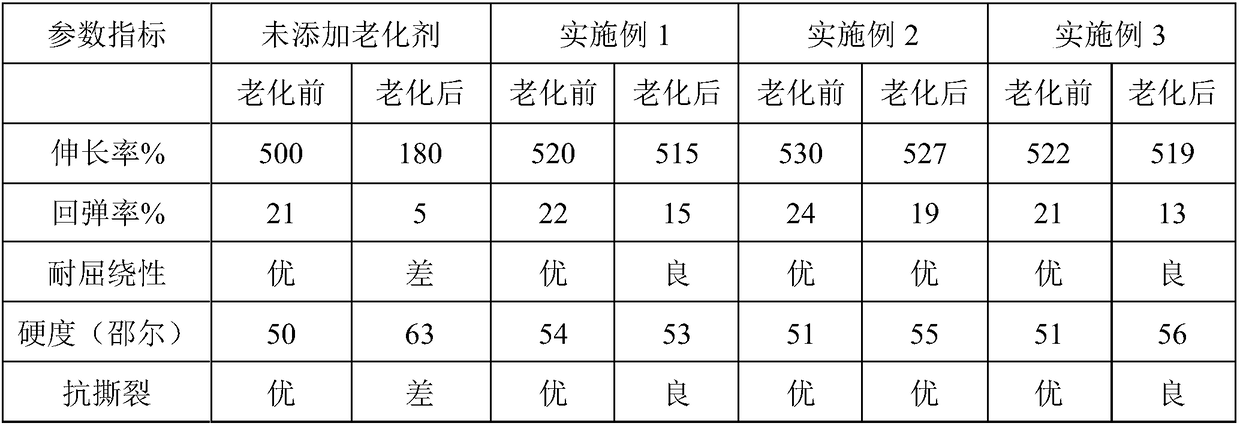

Examples

Embodiment 1

[0033] The invention provides a kind of antioxidant preparation method that is used for nitrile rubber, and concrete operation steps are as follows:

[0034] Step 1, add N-(4-methylphenyl) 2-N'-(1,3-dimethylbutyl) p-phenylenediamine antioxidant into ethanol organic solvent and stir evenly, then add vinyl bis Stearamide is mixed evenly to obtain a mixed solution;

[0035] Step 2, under stirring conditions, add water and ethyl acrylate to the mixed solution prepared in the step 1, after mixing evenly, continue to add p-hydroxyanisole dropwise, control the reaction temperature to 50°C; the dropping time is 20min, the stirring speed is 80r / min;

[0036] Step 3: After the p-hydroxyanisole is added dropwise in step 2, the temperature is raised to 70°C, and the temperature rise rate is controlled to be 2°C / min. After the temperature is raised to 70°C, the reaction is continued for 5 hours, and then cooled to room temperature. After extraction, The finished product is obtained after...

Embodiment 2

[0045] The invention provides a kind of antioxidant preparation method that is used for nitrile rubber, and concrete operation steps are as follows:

[0046] Step 1, add N-(4-methylphenyl) 2-N'-(1,3-dimethylbutyl) p-phenylenediamine antioxidant into ethanol organic solvent and stir evenly, then add vinyl bis Stearamide is mixed evenly to obtain a mixed solution;

[0047] Step 2, under stirring conditions, add water and ethyl acrylate to the mixed solution prepared in the step 1, after mixing evenly, continue to add p-hydroxyanisole dropwise, control the reaction temperature to 50°C; the dropping time is 30min, the stirring speed is 90r / min;

[0048] Step 3, after the p-hydroxyanisole was added dropwise in step 2, the temperature was raised to 70°C, and the heating rate was controlled to be 2°C / min. After the temperature was raised to 70°C, the reaction was continued for 8 hours, and then cooled to room temperature, after extraction, The finished product is obtained after was...

Embodiment 3

[0057] The invention provides a kind of antioxidant preparation method that is used for nitrile rubber, and concrete operation steps are as follows:

[0058] Step 1, add N-(4-methylphenyl) 2-N'-(1,3-dimethylbutyl) p-phenylenediamine antioxidant into ethanol organic solvent and stir evenly, then add vinyl bis Stearamide is mixed evenly to obtain a mixed solution;

[0059] Step 2, under stirring conditions, add water and ethyl acrylate to the mixed solution prepared in step 1, after mixing evenly, continue to drop p-hydroxyanisole, control the reaction temperature to 50 °C; the dropping time is 25min, the stirring speed is 85r / min;

[0060] Step 3: After the p-hydroxyanisole is added dropwise in step 2, the temperature is raised to 70°C, and the temperature rise rate is controlled to be 2°C / min. After the temperature is raised to 70°C, the reaction is continued for 6 hours, and then cooled to room temperature. After extraction, The finished product is obtained after washing an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com