Active start timing control in failure mode

A controller and restart technology, applied in the output power conversion device, the conversion of DC power input to DC power output, electrical components, etc., can solve the problem that the restart timing cannot be accurately predicted.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

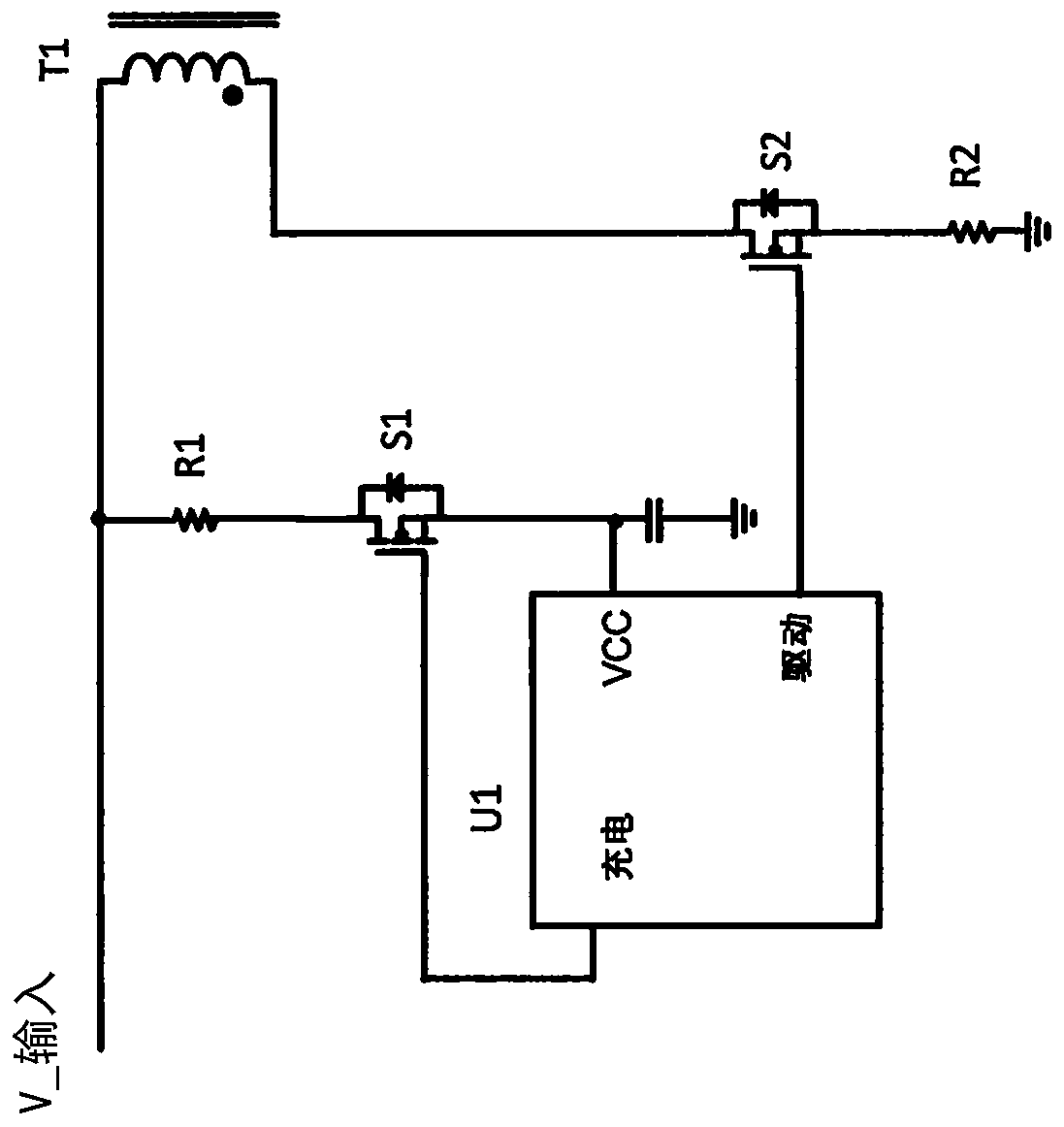

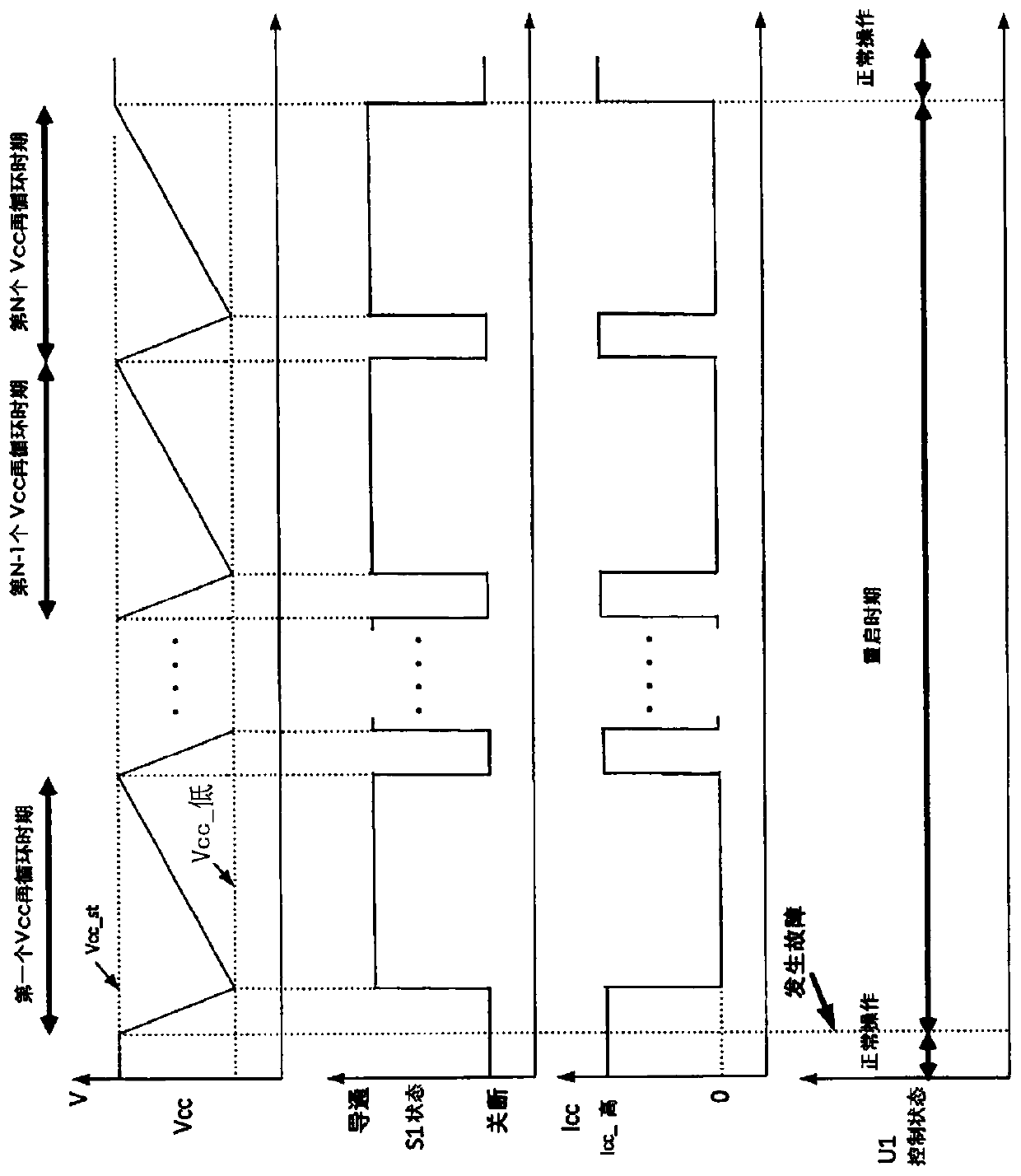

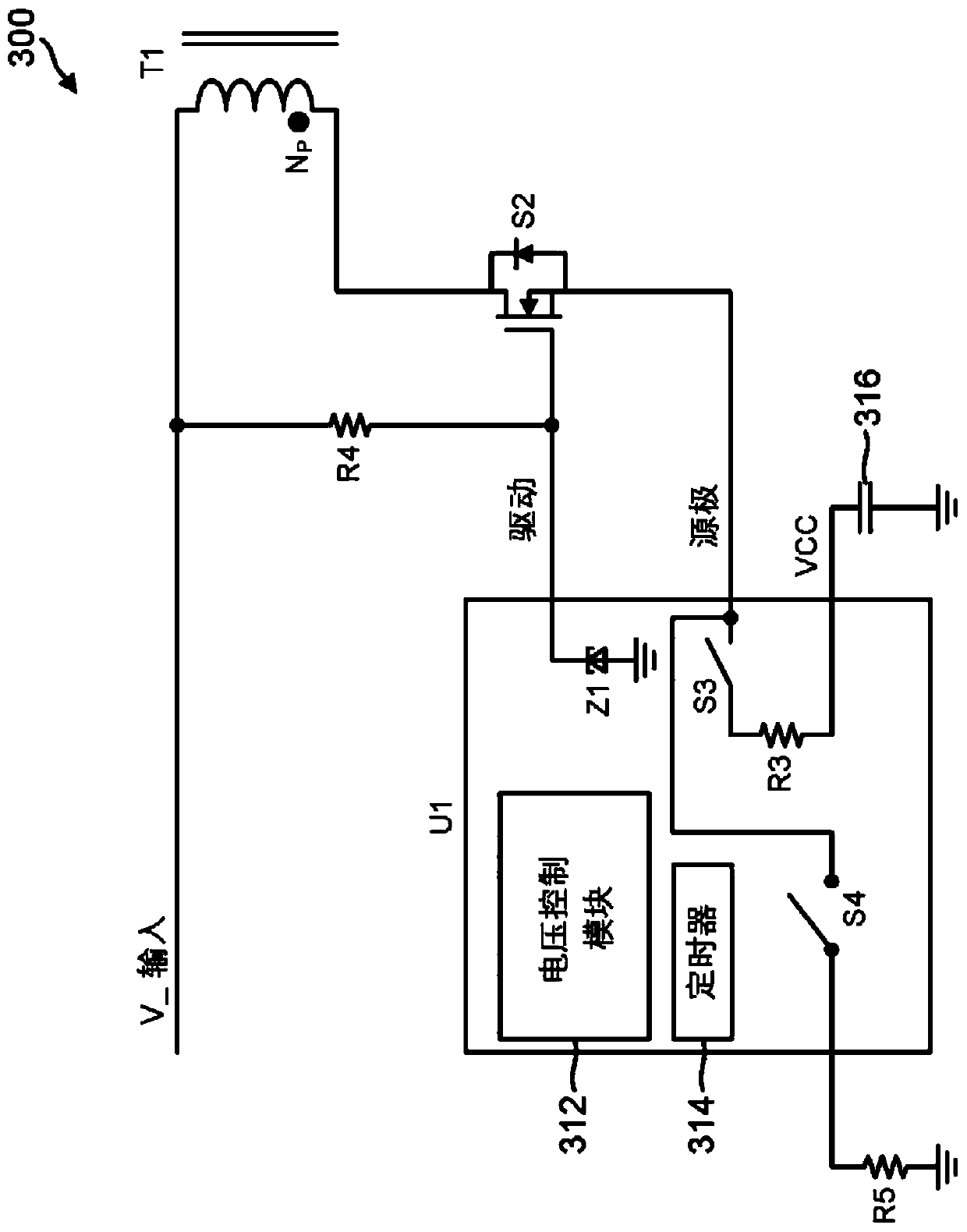

[0016] The following discussion will focus on flyback converters. However, it will be appreciated that the improved restart period disclosed herein may be implemented in other types of switching power converters, such as buck converters, boost converters, or buck-boost converters. exist image 3 An example flyback converter 300 configured for a restart period independent of input voltage is shown in . As is known in the field of flyback converters, the flyback converter 300 includes a power switch transistor S2 in series with the primary winding of a transformer T1, a control configured to control the on and off states of the power transistor switch S2. device U1. During normal operation, the on and off states of the power switching transistor S2 are controlled by the drive terminal of the controller U1 coupled to the gate of the power switching transistor S2, and the controller U1 can maintain the output to the flyback converter 300 voltage output regulation (for simplicit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com