Compact type double-actuation assembly piezoelectric stick-slip driving device and driving method thereof

A technology for actuating components and driving devices, which can be applied to piezoelectric effect/electrostrictive or magnetostrictive motors, electrical components, generators/motors, etc., which can solve the difficulty in adjusting friction force and the limited performance of piezoelectric drives and other problems to achieve the effect of improving output performance, output force, and output speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

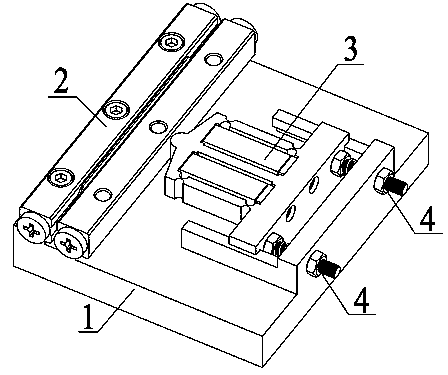

[0020] Specific implementation mode one: combine Figure 1~Figure 7 Describe this embodiment. This embodiment provides a specific implementation of a compact dual-actuation component piezoelectric stick-slip drive device. The specific embodiment of the compact dual-actuation component piezoelectric stick-slip drive device is described as follows:

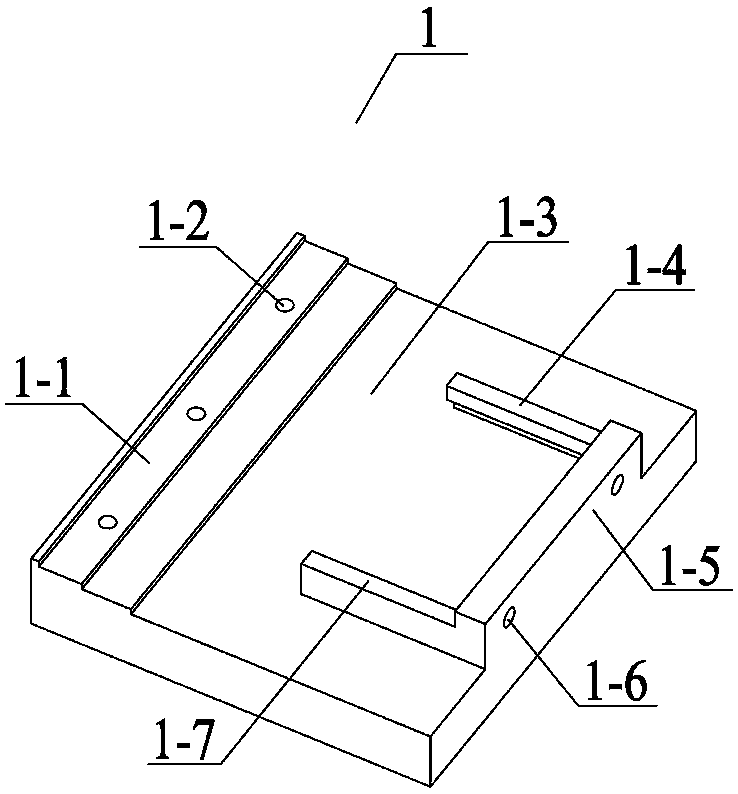

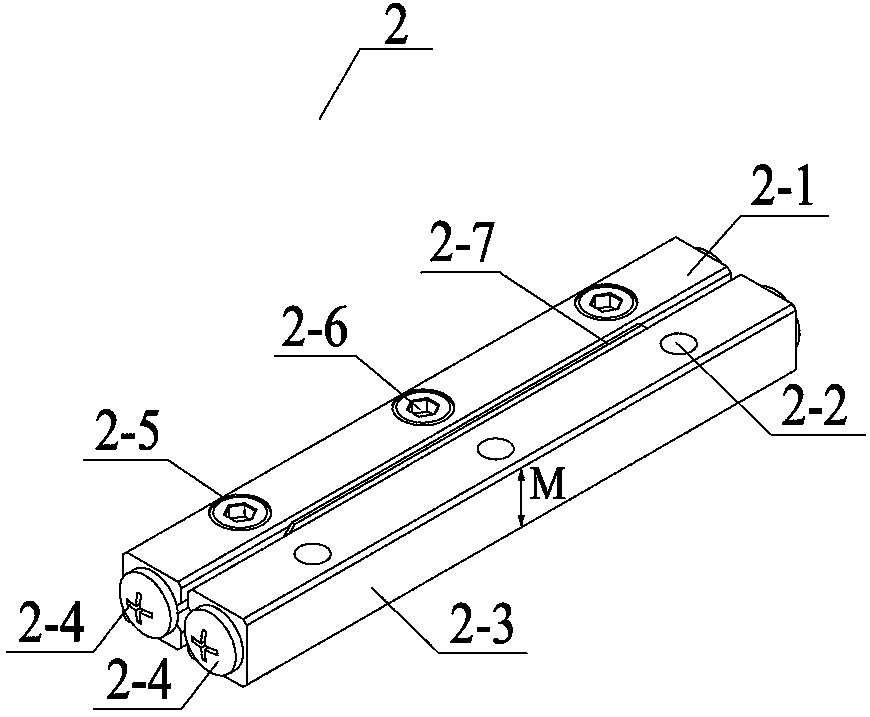

[0021] The compact dual-actuation assembly piezoelectric stick-slip driving device is composed of a workbench 1, a double-rail mover 2, a double-drive stator 3 and a thread loader 4; the double-rail mover 2 is fixedly installed on the workbench The mover of 1 is installed on the plane 1-1, the double drive stator 2 is installed on the stator installation plane 1-3, and the threaded loader 4 is connected to the workbench 1 and the double drive stator 3 through screw fit.

[0022] The workbench 1 can be made of stainless steel, and the workbench 1 includes a mover installation plane 1-1, a mover installation screw hole 1-2, a stator ...

specific Embodiment approach 2

[0026] Specific implementation mode two: combination Figure 8 This embodiment is described. This embodiment provides a specific implementation of a compact dual-actuation component piezoelectric stick-slip driving device driving method. The driving method of a compact dual-actuation component piezoelectric stick-slip driving device is as follows shown.

[0027] The composite excitation electric signal adopted in the driving method is realized. The composite excitation electric signal includes the friction control wave and the driving wave. By superimposing the friction control wave on the fast energization stage of the driving wave, the double drive stator is excited to be in the microscopic state during the rapid deformation stage. Secondary high-frequency resonance state, based on the ultrasonic anti-friction effect to reduce the frictional resistance between the double-driven stator and the double-rail mover in the rapid deformation stage; the driving wave is a sawtooth wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com