Four-axis writing manipulator

A technology of manipulators and output shafts, applied in the direction of manipulators, program-controlled manipulators, manufacturing tools, etc., can solve the problems of clumsiness, inflexibility, falling outside the paper, affecting the writing effect, etc., and achieve the effect of high flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with accompanying drawing and embodiment of description, specific embodiment of the present invention is described in further detail:

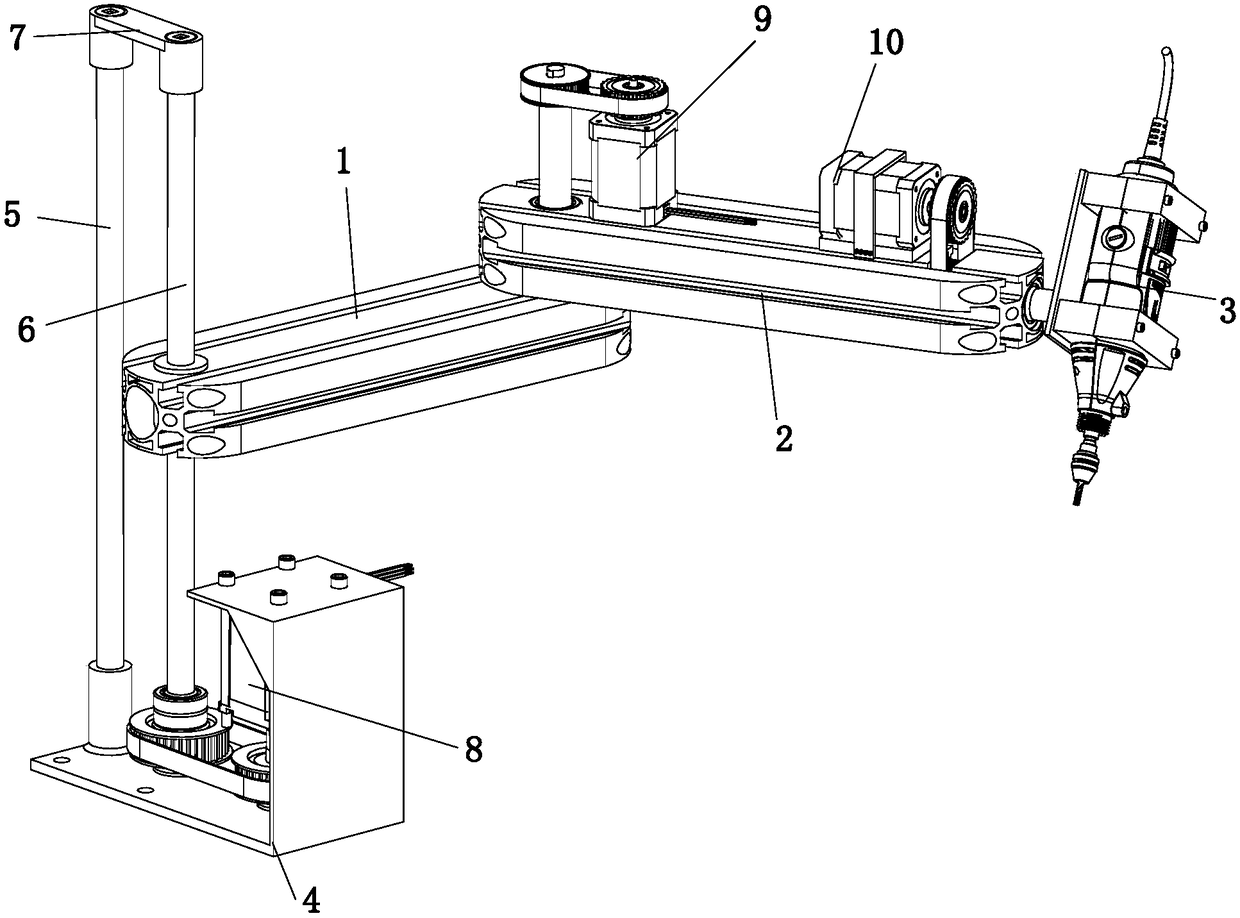

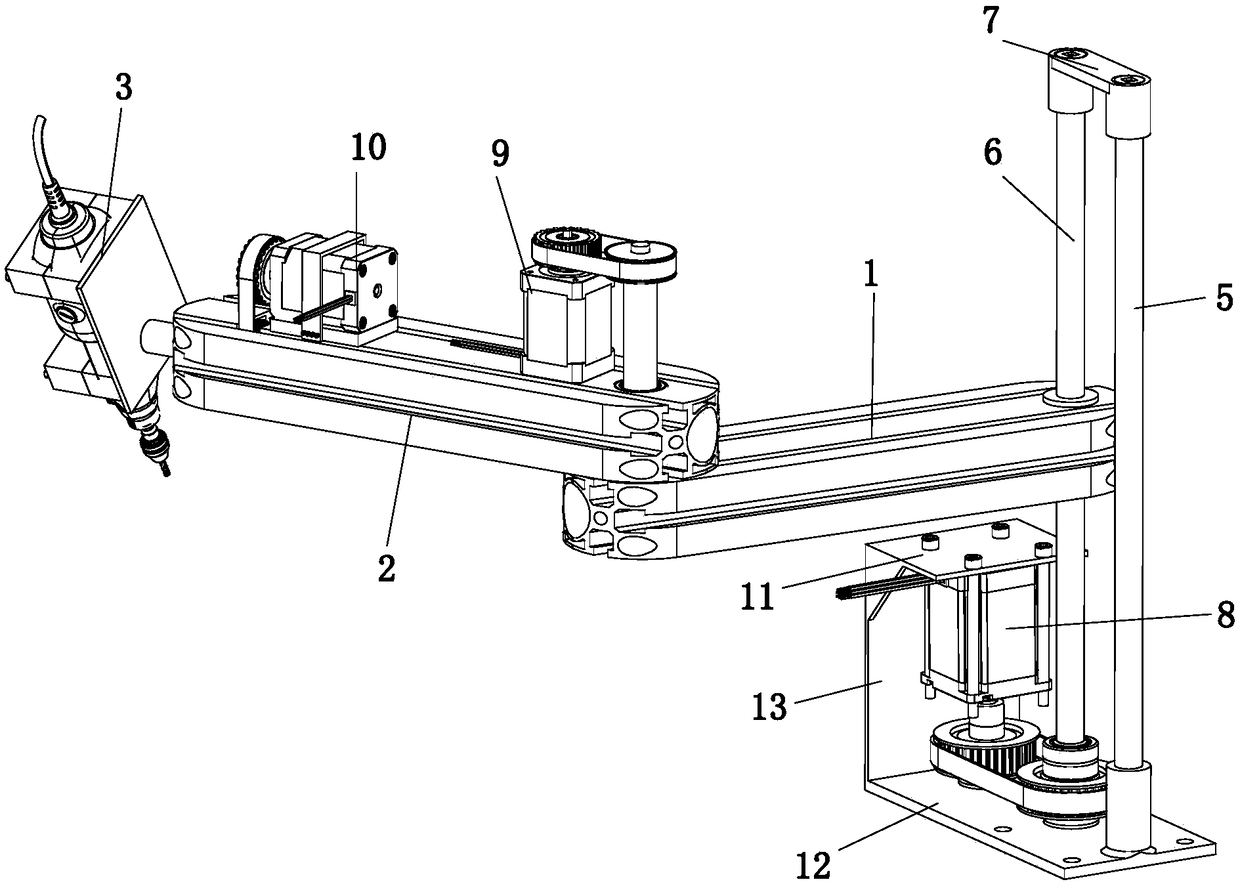

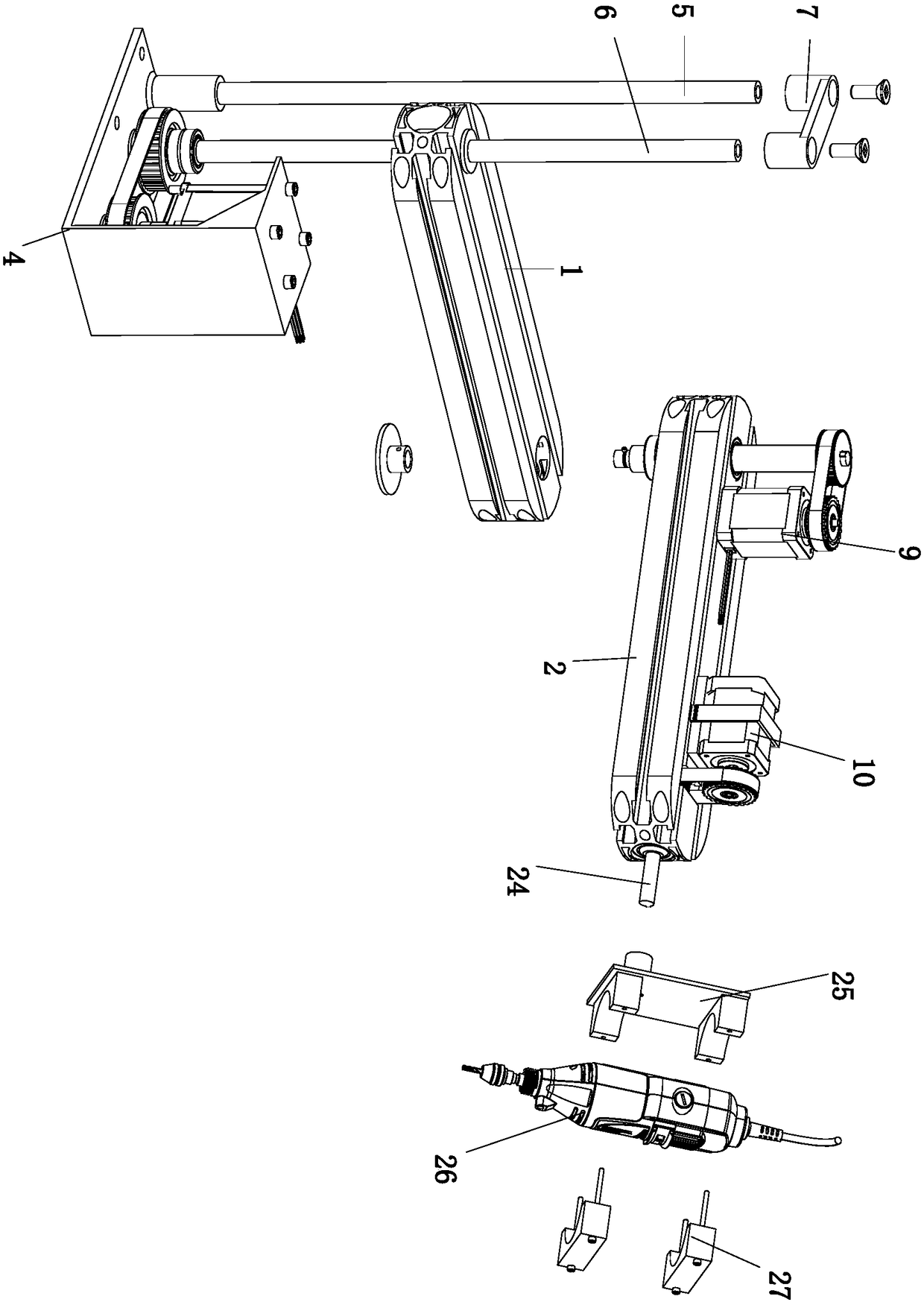

[0025] refer to Figure 1 to Figure 8 A four-axis writing manipulator is shown, including a vertical displacement assembly, a first rotating arm 1, a second rotating arm 2 and a rotating pen head assembly 3, the first rotating arm 1 and the second rotating arm 2 are all arranged horizontally, and vertically The displacement assembly includes a base 4, a supporting column 5 and a rotating column 6 that are all vertically arranged. The bottom of the supporting column 5 is fixedly inserted on the base 4, and the bottom of the rotating column 6 is rotatably inserted on the base 4. The supporting column 5 It is connected with the top of the rotating column 6 through a connecting plate 7, and the first motor 8 is fixedly installed on the base 4. The output shaft of the first motor 8 is connected to the bottom of the rotat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com