Horizontal clamping mechanism, robot clamping claw and clamping method

A clamping mechanism and clamping claw technology, applied in the field of robotics, can solve the problems of unreasonable design structure of the clamping mechanism, insufficient stability of the clamped objects, and affecting production efficiency, so as to reduce the risk of workpiece falling and make the structural design reasonable and ingenious , the effect of a reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

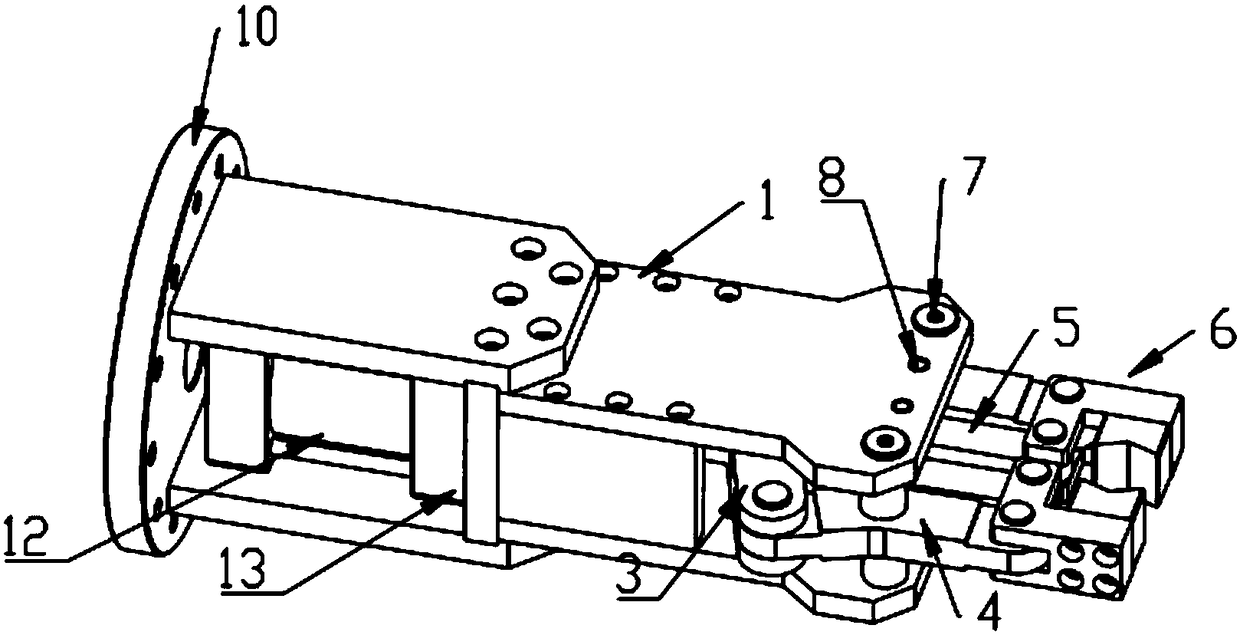

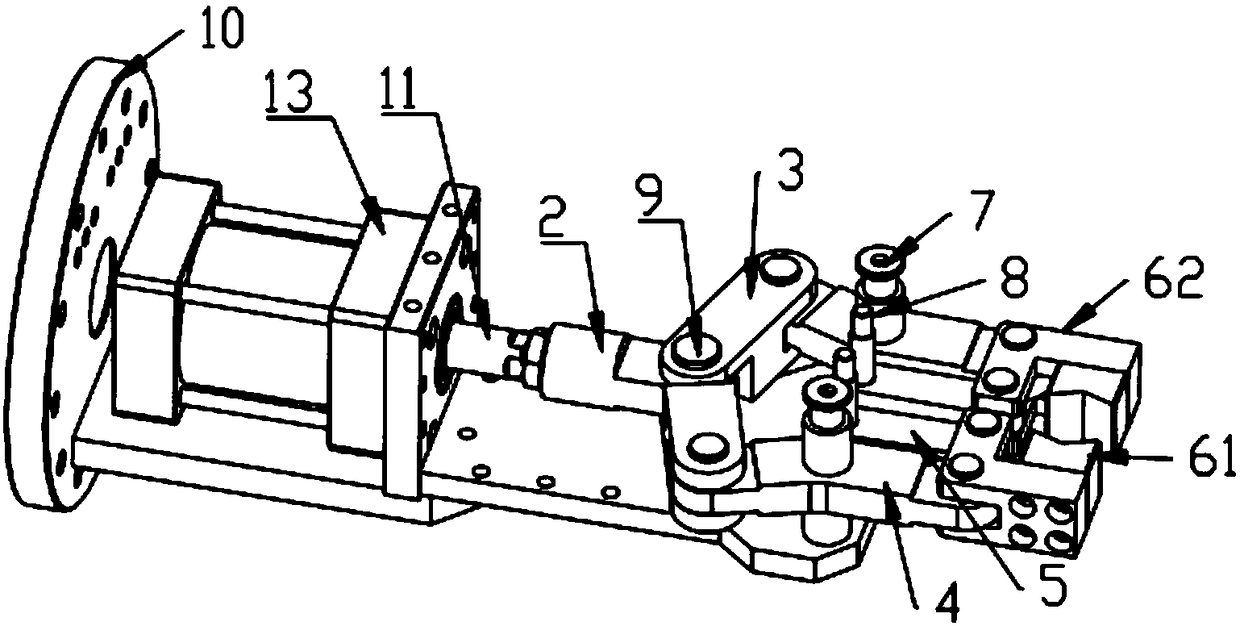

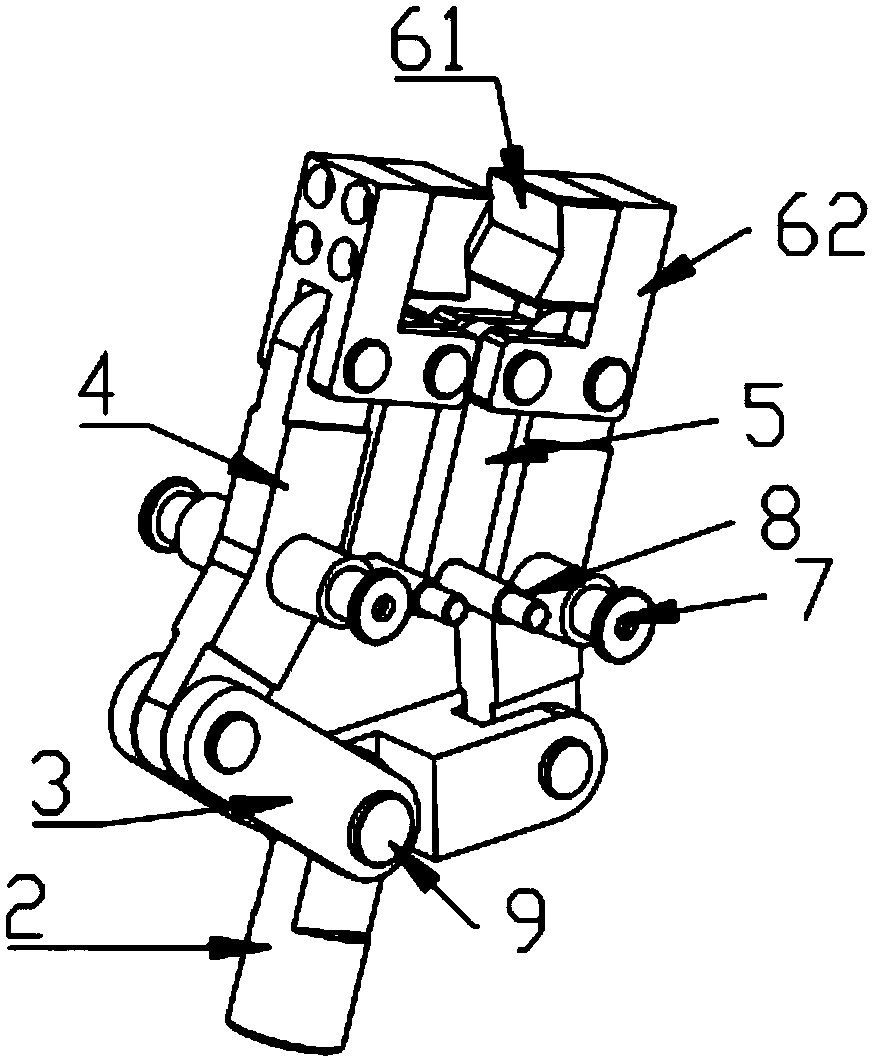

[0028] Examples, see Figures 1 to 6 , a horizontal clamping mechanism provided in this embodiment, including two fixed plates 1, a driving rod 2, two connecting rods 3, two levers 4, two guiding rods 5 and two sets of clamp bodies 6, through which the levers 4 The middle part is provided with a first rotating shaft 7, and a second rotating shaft 8 is provided through the rear end of the guide rod, and the two ends of the first rotating shaft 7 and the second rotating shaft 8 are respectively connected with the two fixed plates 1 Fixed connection, that is, the lever 4 can rotate relative to the fixed plate 1 through the first rotating shaft 7, and the guide rod 5 can rotate relative to the fixed plate 1 through the second rotating shaft 8 turn.

[0029] see image 3 , the front end of the drive rod 2 is hinged to the rear ends of the two connecting rods 3, the front end of the connecting rod 3 is hinged to the rear end of the lever 4, and the clamp body 6 is connected to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com