Oxford cloth boiling-off tank with improved strength

A technology of increasing strength and scouring, which is applied in the processing of textile materials, textiles and papermaking, liquid/gas/steam textile material processing, etc. It can solve the unsatisfactory strength of the scouring tank, the inconvenient opening and closing, and the sealing of the tank cover Poor performance and other problems, to achieve the effect of saving labor in the opening process, simple structure, and improving sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

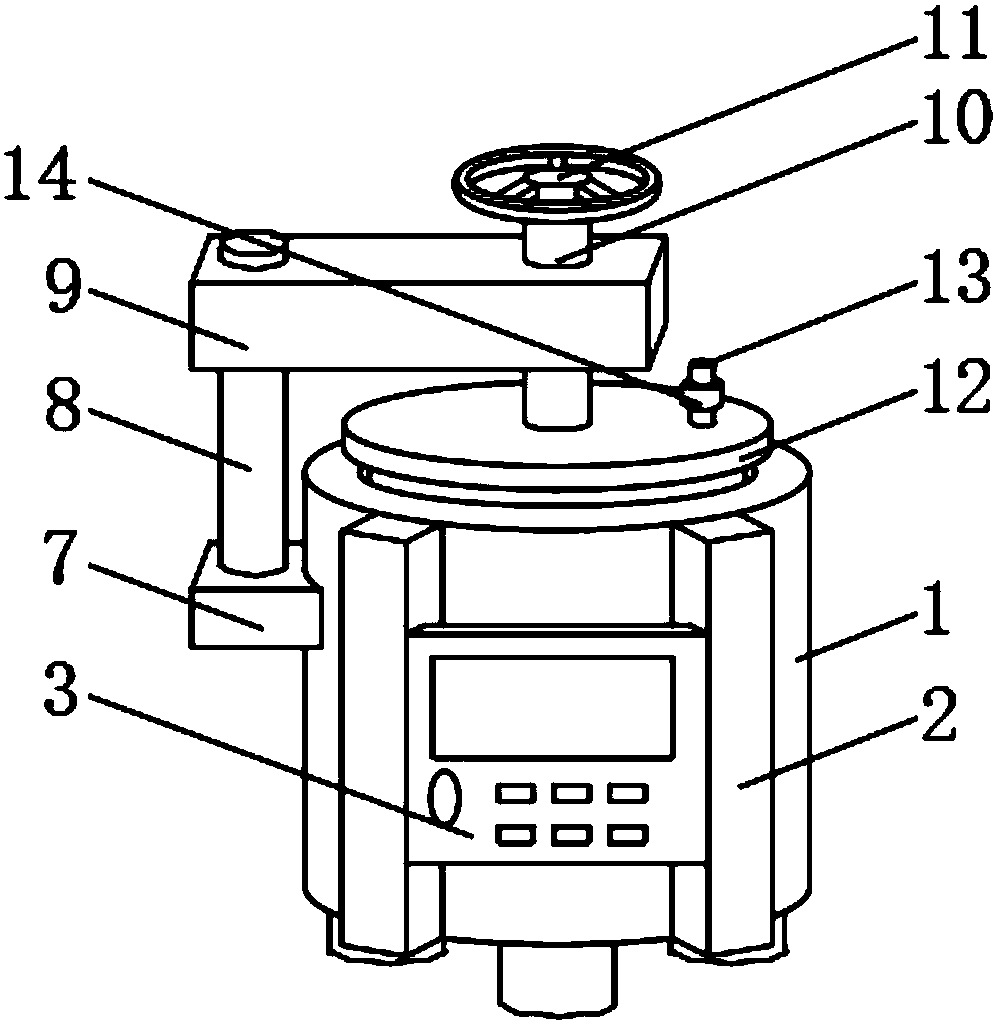

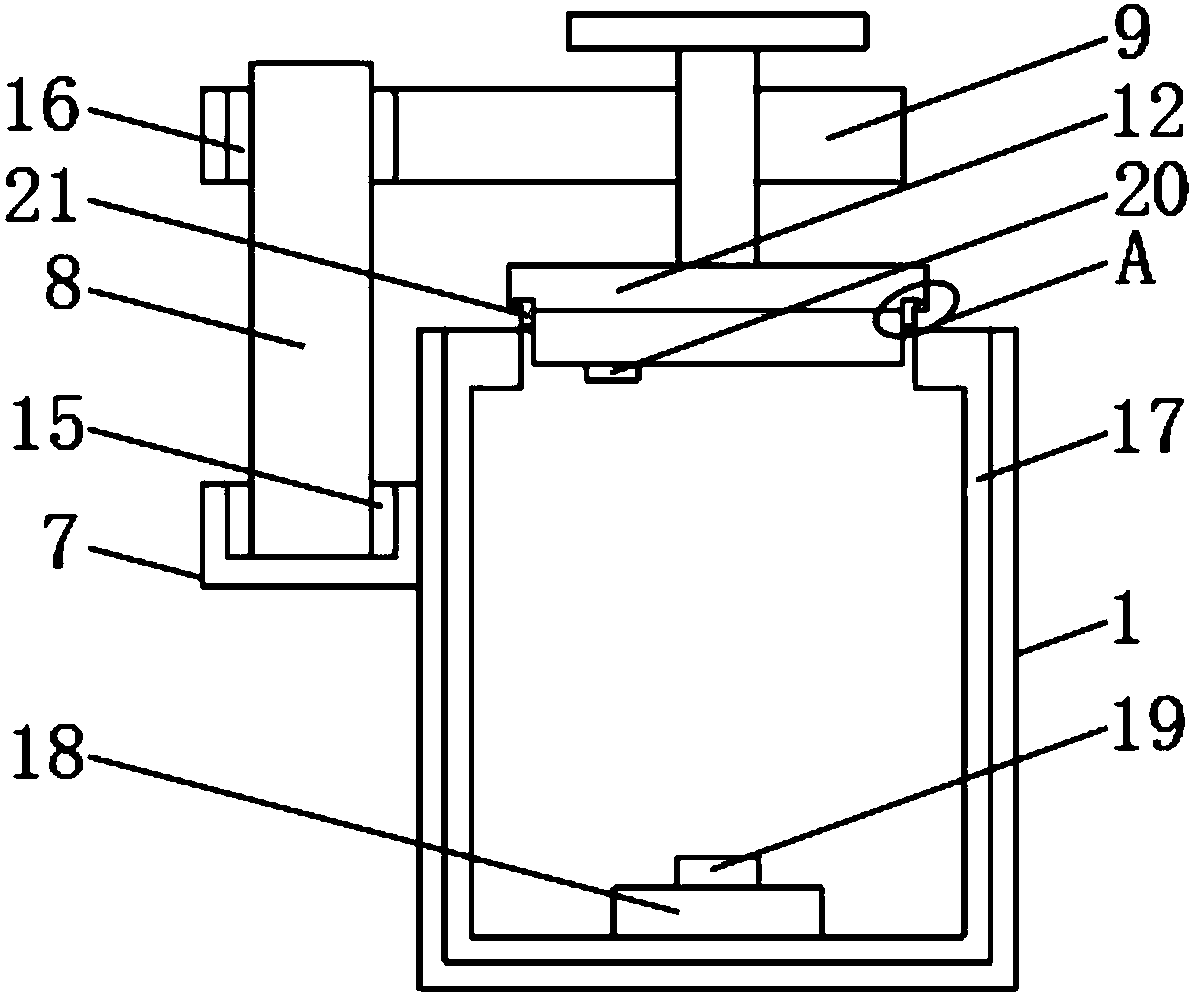

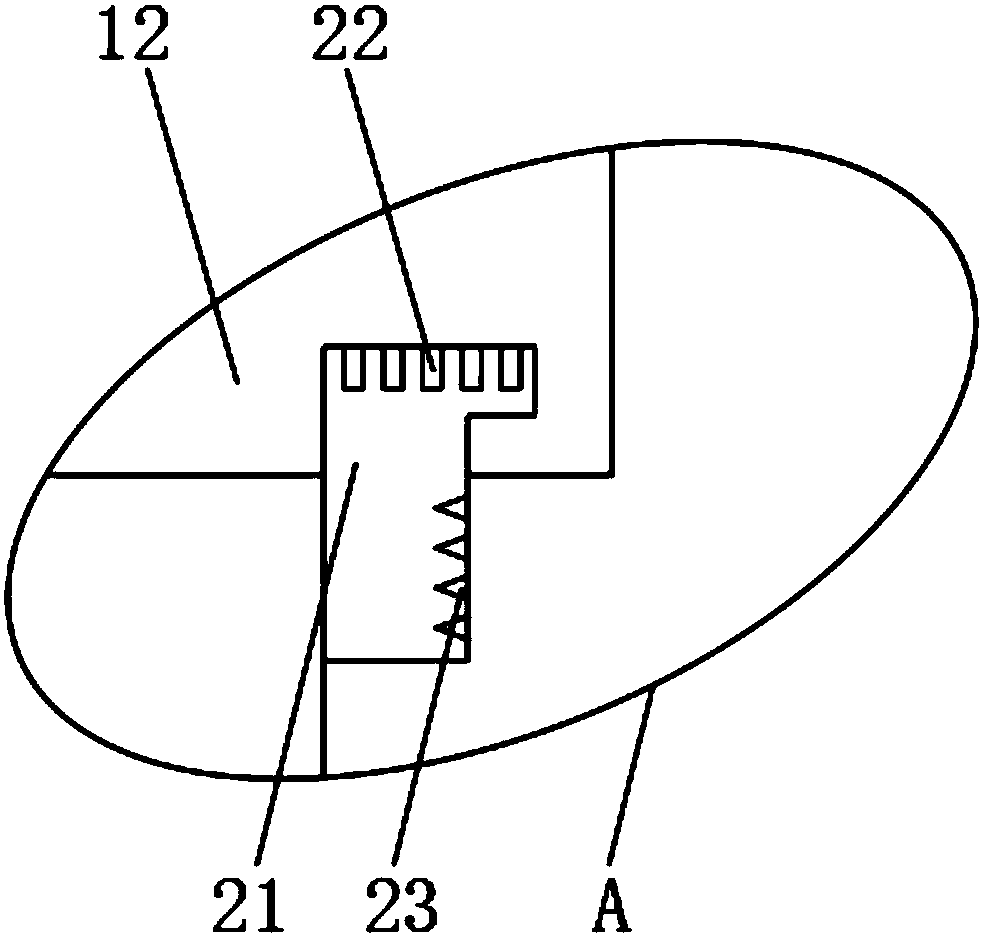

[0019] Such as Figure 1-5 As shown, an Oxford cloth scouring tank capable of increasing strength includes a heat-insulating jacket 1, and a reinforcing rib 2 is fixedly connected to the outer surface of the front end of the temperature-insulating jacket 1, and the reinforcing rib 2 can greatly enhance the strength of the scouring tank. It is more practical to avoid dangerous situations, and a control panel 3 is fixedly installed on one side of the outer surface of the reinforcing rib 2, and the front outer surface of the control panel 3 is provided with a display screen 4, a power switch 5 and an operation key 6, and a temperature insulation jacket One side of the outer surface of 1 is fixedly connected with an ear seat 7, and the outer surface o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com