Diversion tunnel blockage structure and method based on karst landform

A diversion tunnel and karst technology, applied in water conservancy projects, sea area projects, hydroelectric power stations, etc., can solve problems such as narrow construction surfaces and difficult sealing, and achieve the effects of high safety, low construction cost, and short construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

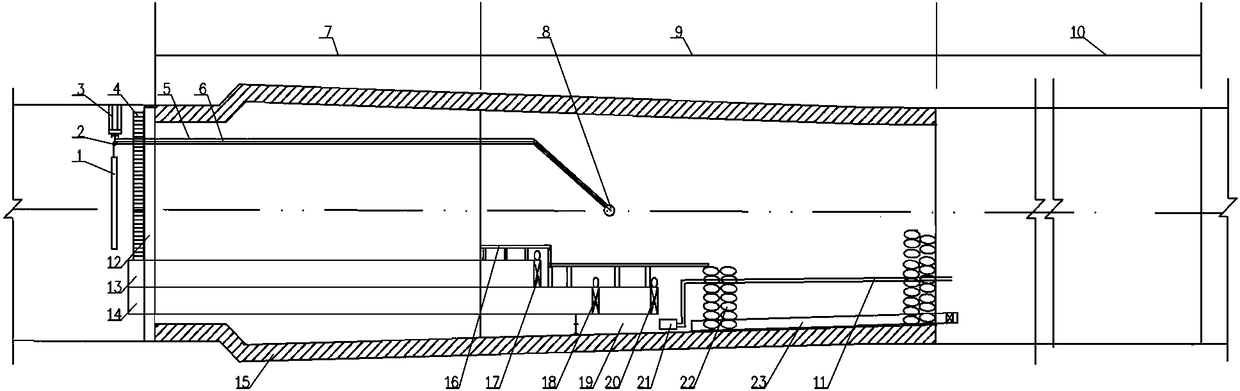

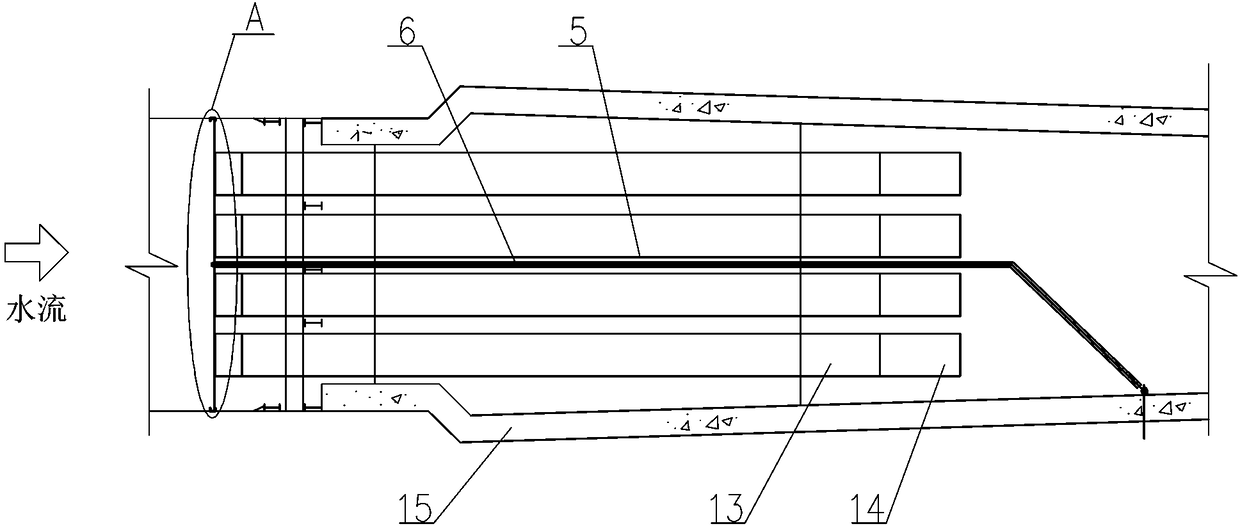

[0041] see Figure 1-8 , based on the diversion tunnel plugging structure of karst landform, the first section of temporary plug 7, the second section of temporary plug 9 and the permanent plug 10 are sequentially arranged inside the concrete lining 15 of the original diversion tunnel along the water flow direction; A water-retaining steel gate 1 is installed upstream of the first section of temporary plug 7, and behind the water-retaining steel gate 1, a stacking beam door 4 is installed. The bottom of the concrete lining 15 is provided with a bottom drainage steel pipe 14 and a top drainage steel pipe 13. The two layers of drainage steel pipes are stacked and arranged. A first disc valve 17 is installed at the water outlet of the top drainage steel pipe 13. There are two second butterfly valves 18 and third butterfly valves 20 arranged at intervals. By adopting the above diversion tunnel sealing structure, the diversion tunnel can be quickly blocked.

[0042] Further, the ...

Embodiment 2

[0051] Any one of the diversion tunnel plugging structures based on karst landforms, it comprises the following steps:

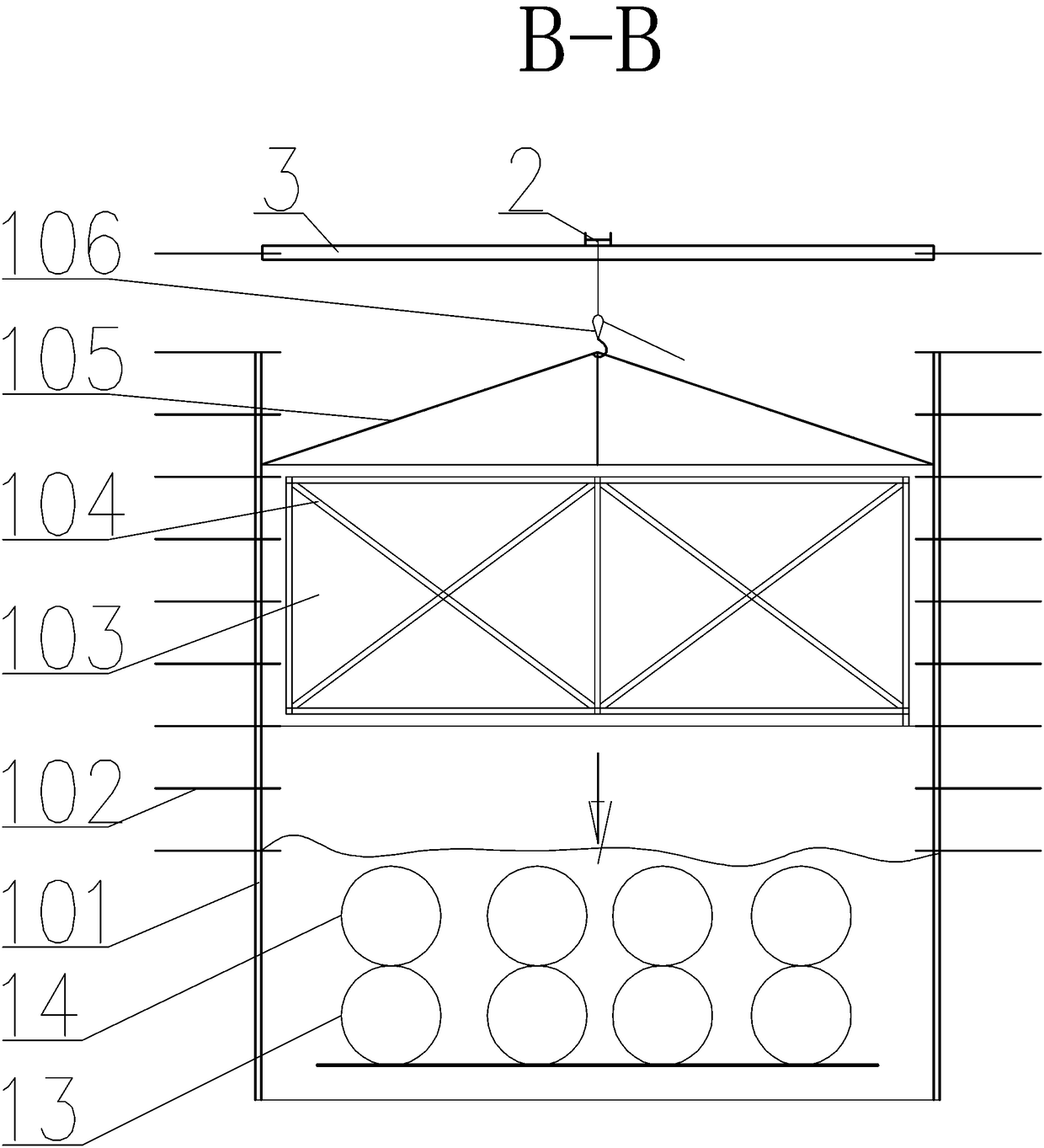

[0052] Step1, Build the construction passage and scaffolding working platform: In order to quickly reach the working surface, the construction road is determined by comprehensively considering factors such as equipment and material transportation, pipeline laying and safe evacuation passages, and a full house of steel pipe supports is erected from the entrance to the temporary plug. The left panel is used as For the transportation channel, steel formwork is laid on the whole line; the right side is covered with bamboo pedals, and the air supply pipe and pump pipe are arranged on the side wall; The first floor is used as a concrete storage platform, and the third floor is used as a reinforcement platform;

[0053] Step2, install the water-retaining steel gate: first, install two door panel columns 101 at the entrance of the diversion tunnel as the guide rail ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com