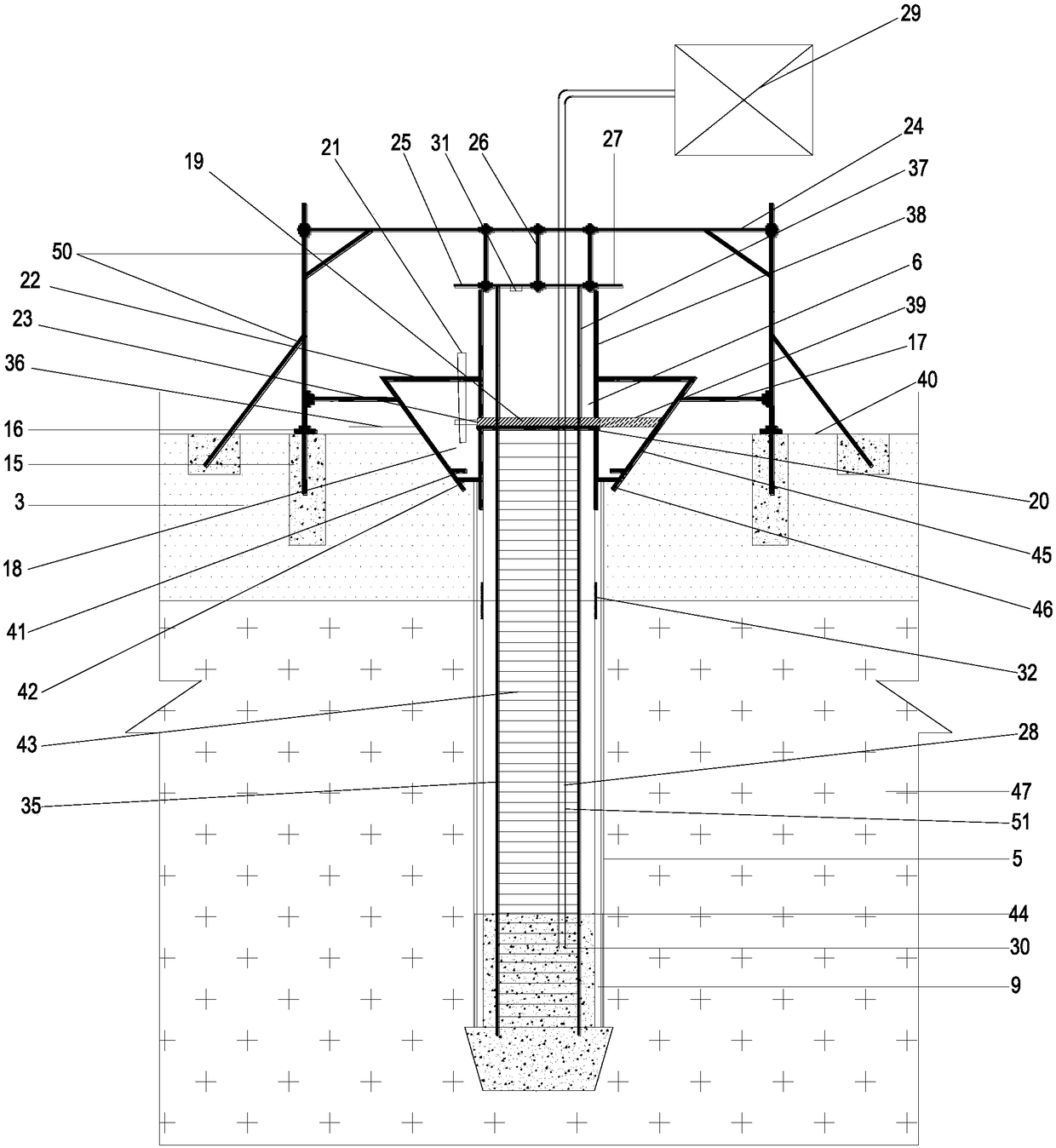

Deep thick mud pool cast-in-situ bored pile and construction method

A technology for bored piles and mud pools, applied in the field of foundation engineering, can solve problems such as inability to meet construction requirements, difficult construction organization, etc., and achieve the effects of easier guarantee of cutting hole quality, improved construction quality, and prevention of floating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be further described below in conjunction with embodiments. The description of the following embodiments is only used to help understand the present invention. It should be pointed out that for those of ordinary skill in the art, without departing from the principle of the present invention, several improvements and modifications can be made to the present invention, and these improvements and modifications also fall within the protection scope of the claims of the present invention.

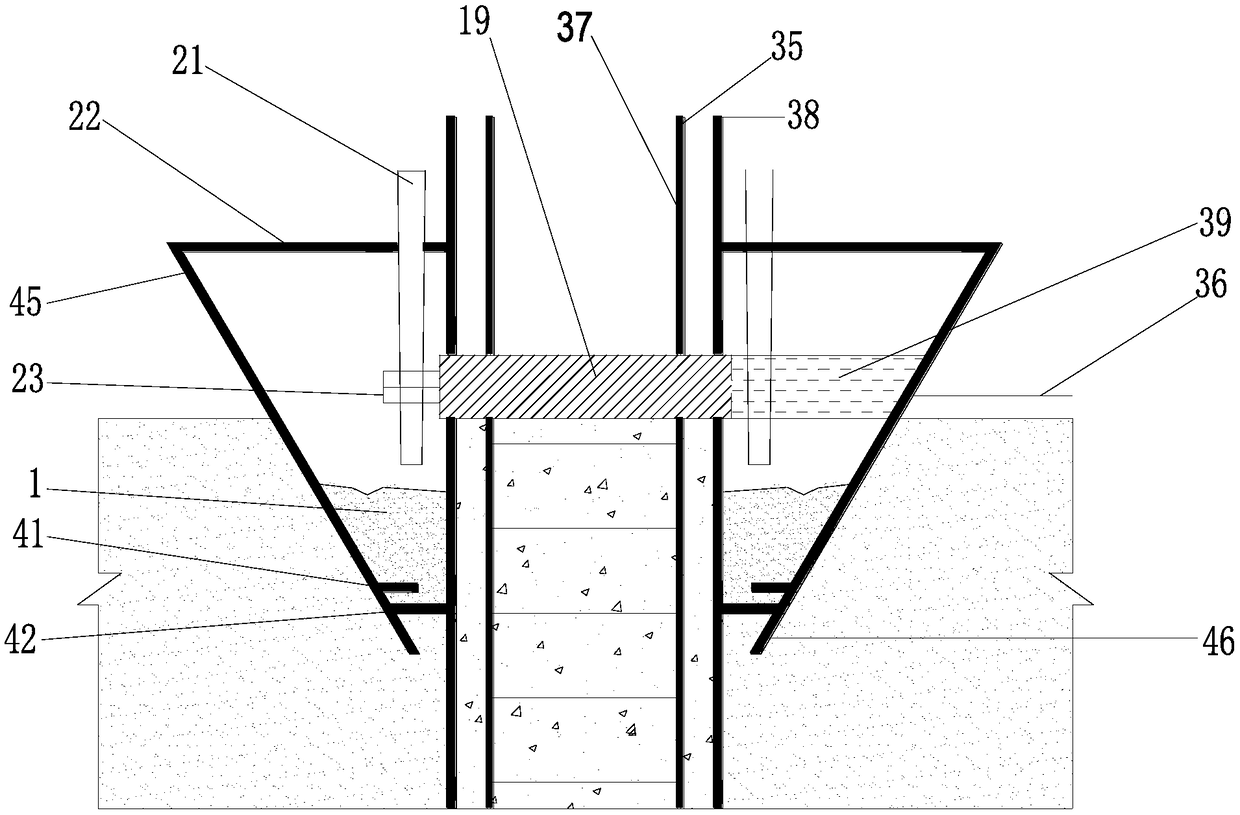

[0051] The deep mud pool bored piles include cement mixing piles 2 and bored piles 48. Both the cement mixing piles 2 and the bored piles 48 enter the uncured area 47 through the shallow solidified hard shell layer 3.

[0052] The cement mixing pile 2 includes a mixing pile retaining hole 4, an enlarged pile top 7 and a partially enlarged pile body 8. The cement mixing pile 2 is placed in the mixing pile retaining hole 4, and the upper end of the cement mixing pile 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com