Water-saving toilet bowl without water tank and manufacturing method of toilet bowl

A manufacturing method and toilet technology, applied to flushing equipment with water tanks, flushing toilets, water supply devices, etc., can solve the problems of lower water resource utilization efficiency, easy blockage, etc., and save the cost of hidden water tanks and installation engineering costs , The production method is simple, the effect of strong discharge capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

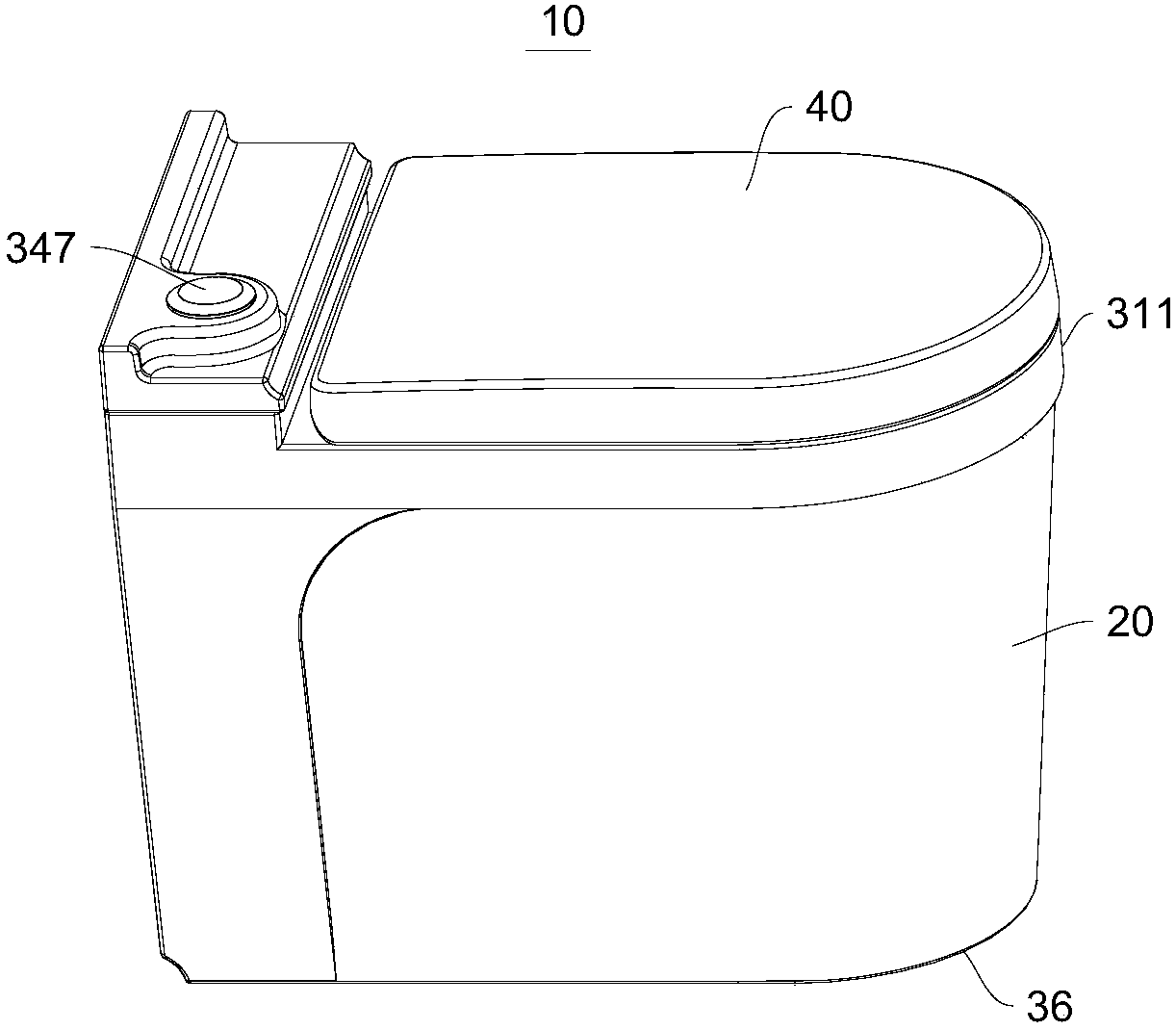

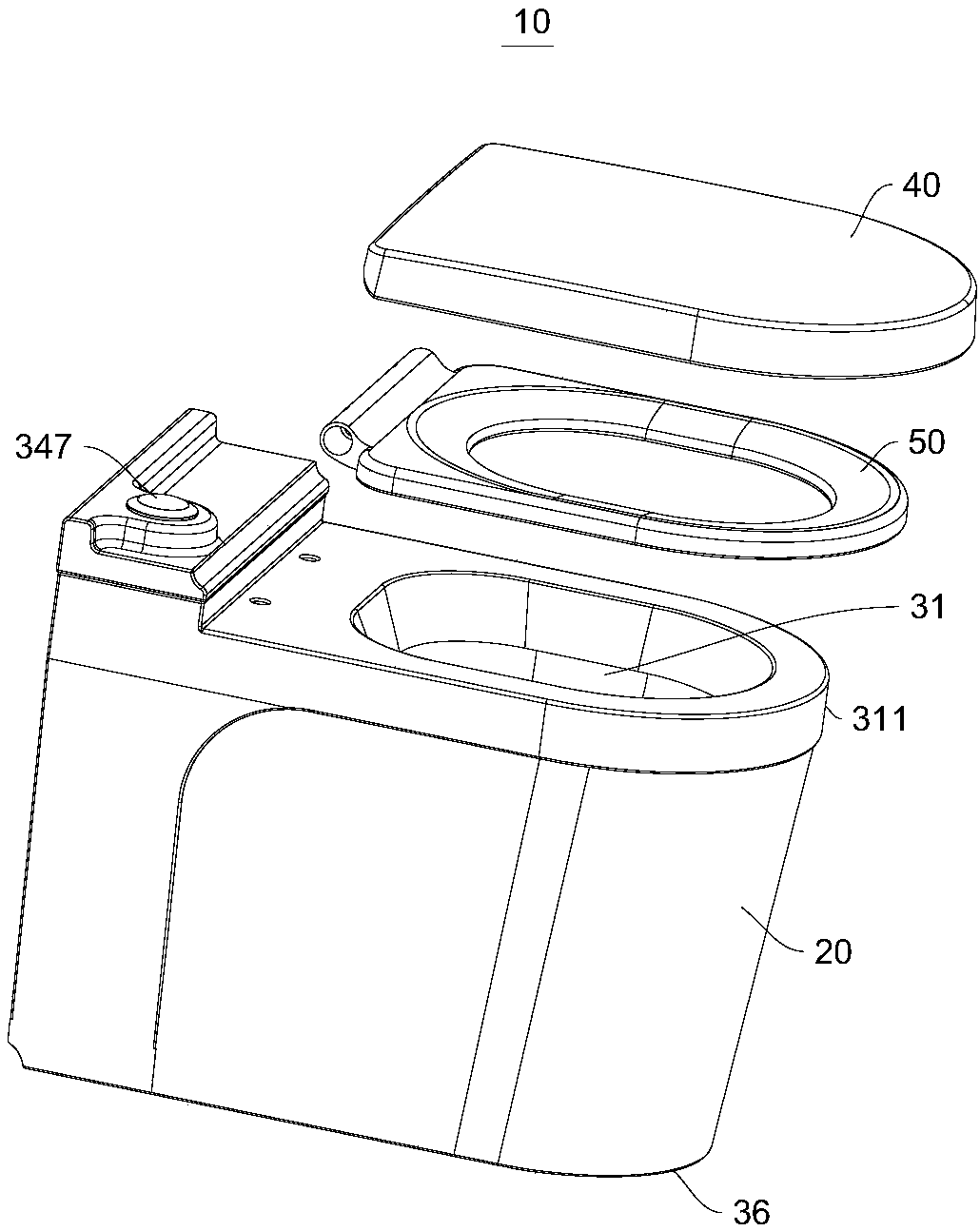

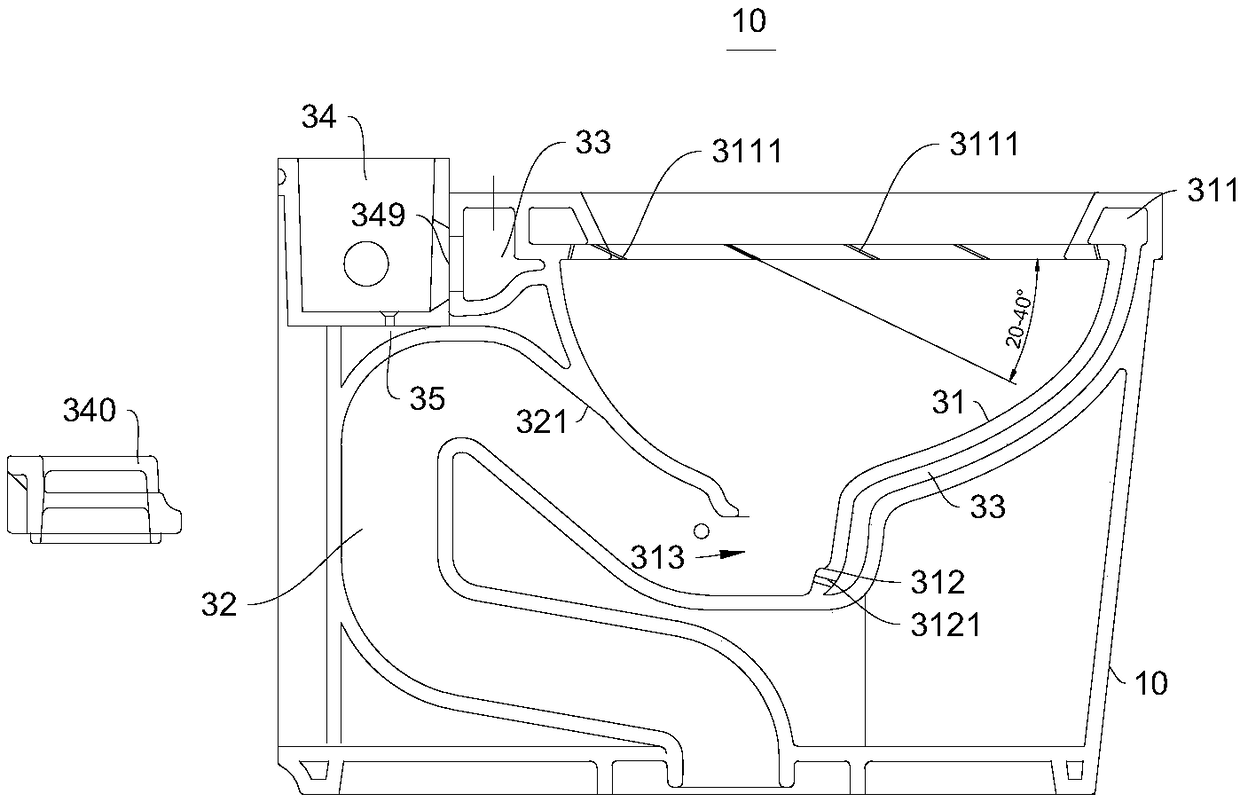

[0043] Please also refer to Figure 1 to Figure 5 , the present embodiment provides a tankless water-saving toilet bowl 10 , which includes a toilet body 20 .

[0044] The toilet body 20 includes a basin cavity 31 , a sewage pipe 32 , a flushing water pipe 33 , a flushing device installation space 34 and a main body shell 36 .

[0045] The toilet body 20 is provided with a water ring 311 (the water ring 311 has a cavity) on the side wall of the pelvic cavity 31, and the bottom of the pelvic cavity 31 is provided with a sewage pipe inlet 313 and a sewage main nozzle for flushing towards the sewage pipe 32. 312. The outside of the bottom of the water circle 311 is connected to the upper periphery of the pelvic cavity 31 and the main body shell 36 .

[0046]The flushing device installation space 34 is arranged at the rear of the toilet body 20 , the opening of the flushing device installation space 34 is upward, and a valve box cover 340 is arranged above the opening to cover t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com