Cable rope steel wire detection mechanism based on leakage magnetic flux detection

A detection mechanism and magnetic flux leakage technology, applied in the direction of material magnetic variables, etc., can solve the problem of not being able to reflect the broken wire of the cable stay, and achieve the effect of improving the ability to distinguish defects, improve stability, and improve the ability to overcome obstacles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solution of the present invention will be described in detail below in combination with the embodiments and the accompanying drawings.

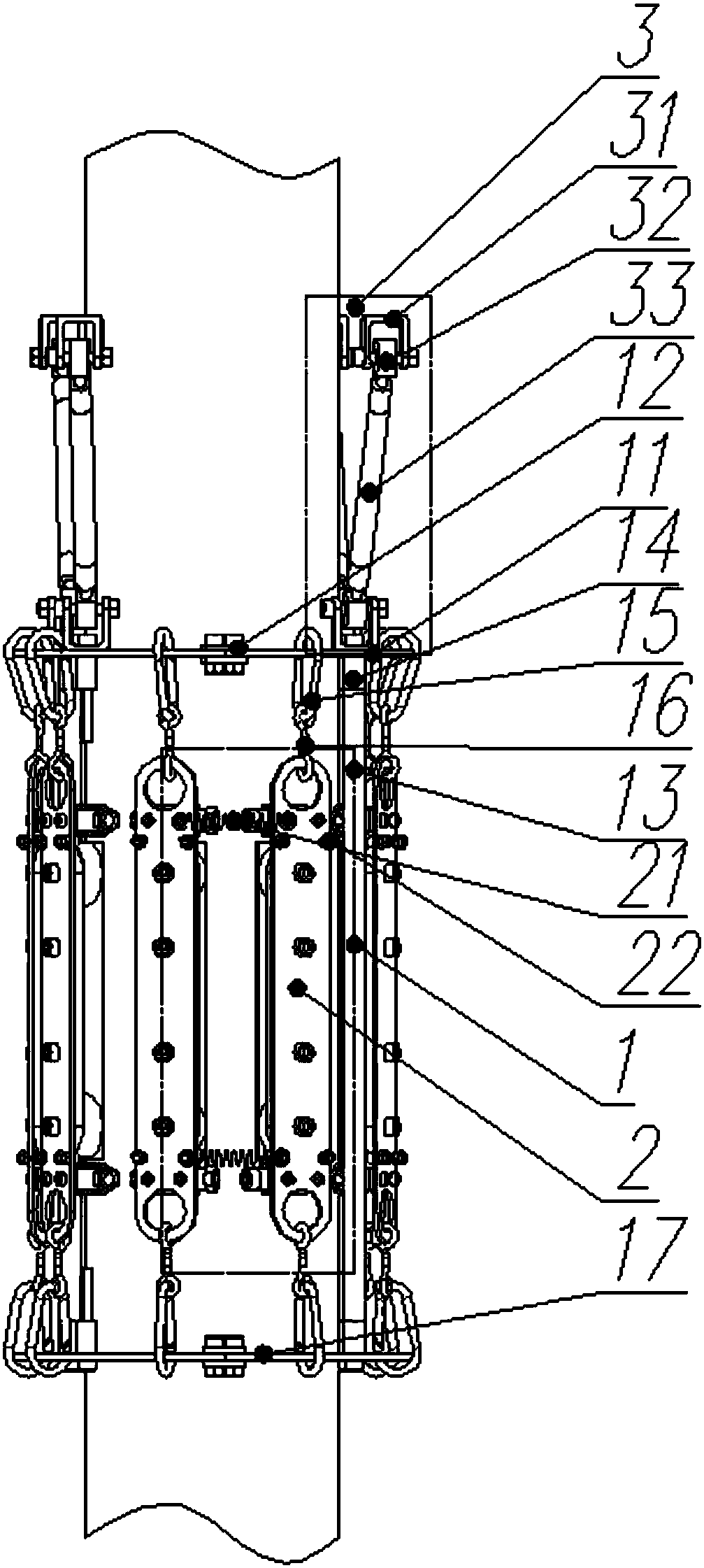

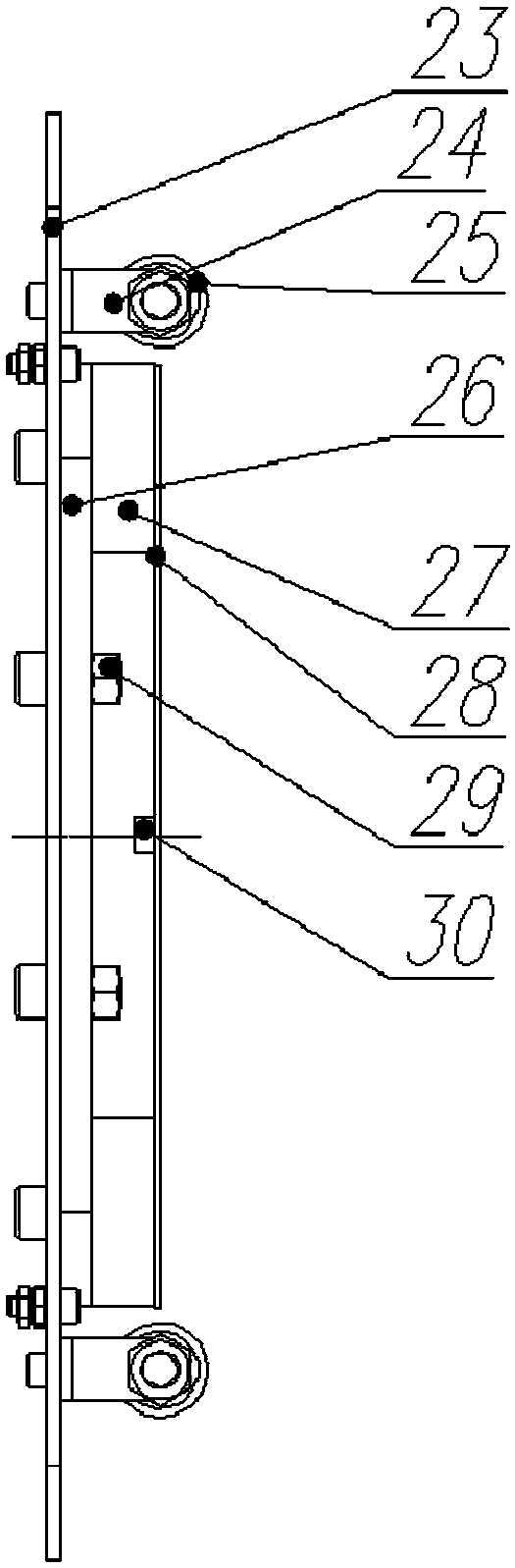

[0022] Such as figure 1 with figure 2 As shown, the cable steel wire detection mechanism based on magnetic leakage flux detection of the present invention includes a car body 1, a flaw detection module 2 connected to the car body and a connecting mechanism 3 connecting the car body and the driving car (not shown). The vehicle body includes an upper mounting ring 11 , a lower mounting ring 17 and a connecting rod 13 , the upper mounting ring includes an upper mounting half ring and a mounting piece 12 , and the connecting rod includes a central tube and a rod end connector 14 . The flaw detection module is composed of a fixed plate 23 , a flaw detection wheel 25 , an armature 26 , a magnet 27 and a cover plate 28 . The armature 26 is connected on the fixed plate 23 , the magnet 25 is adsorbed on the armature 26 , the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com