Ice and snow removing robot for high voltage cable

A technology of high-voltage cables and robots, which is applied to the installation of cables, electrical components, overhead installations, etc., and can solve problems such as the inability to clean ice and snow on high-voltage cables

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

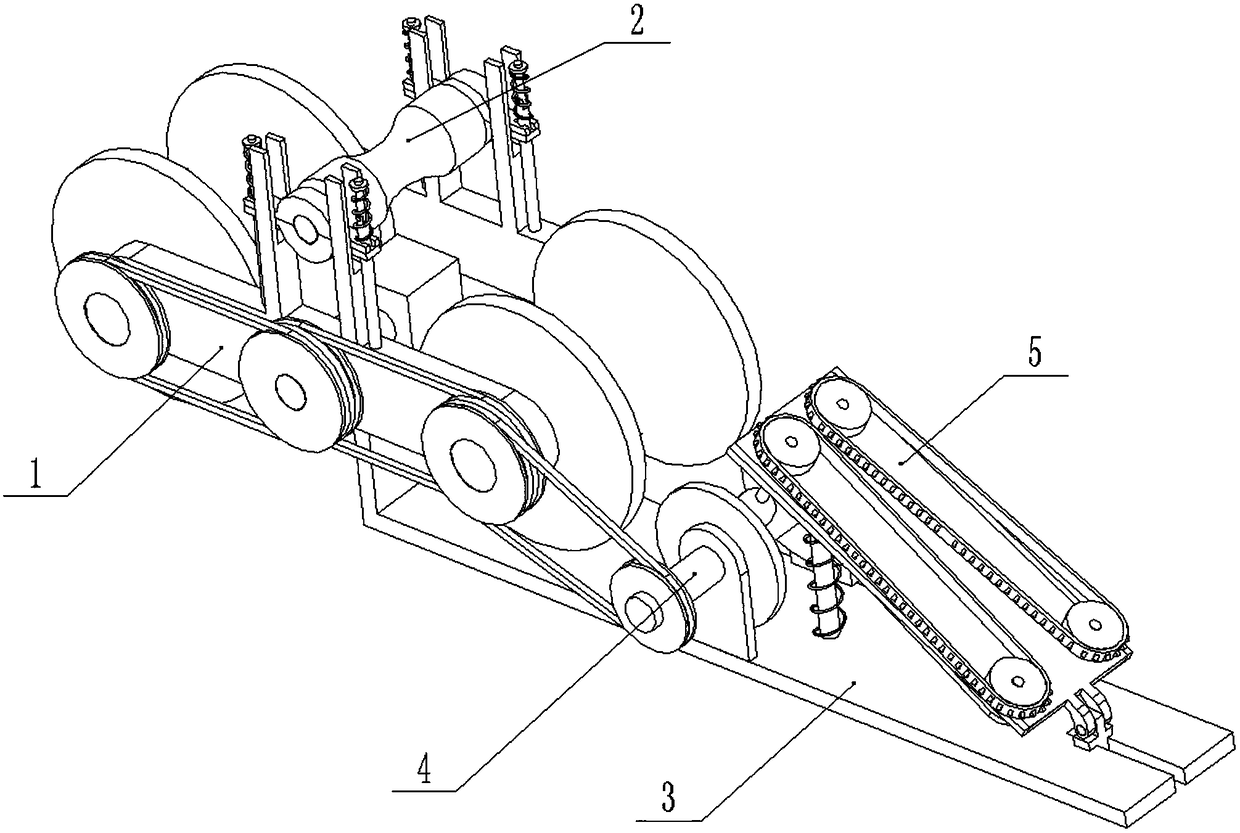

[0029] Combine below Figure 1-10 Describe this embodiment, a high-voltage cable ice and snow removal robot, including a cable lower propulsion device 1, an upper clamping device 2, a cleaning frame 3, a driven grinding disc assembly 4 and a cleaner 5, and the upper clamping device 2 is fixedly connected to At the upper end of the cable propulsion device 1, the cleaning frame 3 is fixedly connected to the lower end of the cable propulsion device 1, the driven grinding disc assembly 4 is rotatably connected to the cleaning frame 3, and the right end of the cleaner 5 slides Hinged on the cleaning frame 3, the left end of the cleaner 5 is slidably connected to the cleaning frame 3, the driven grinding disc assembly 4 is located between the cable lower propulsion device 1 and the cleaner 5, the driven grinding disc assembly 4 is connected with the lower cable propulsion device 1 through a belt transmission, and the driven grinding disc assembly 4 is linked with the cleaner 5; when...

specific Embodiment approach 2

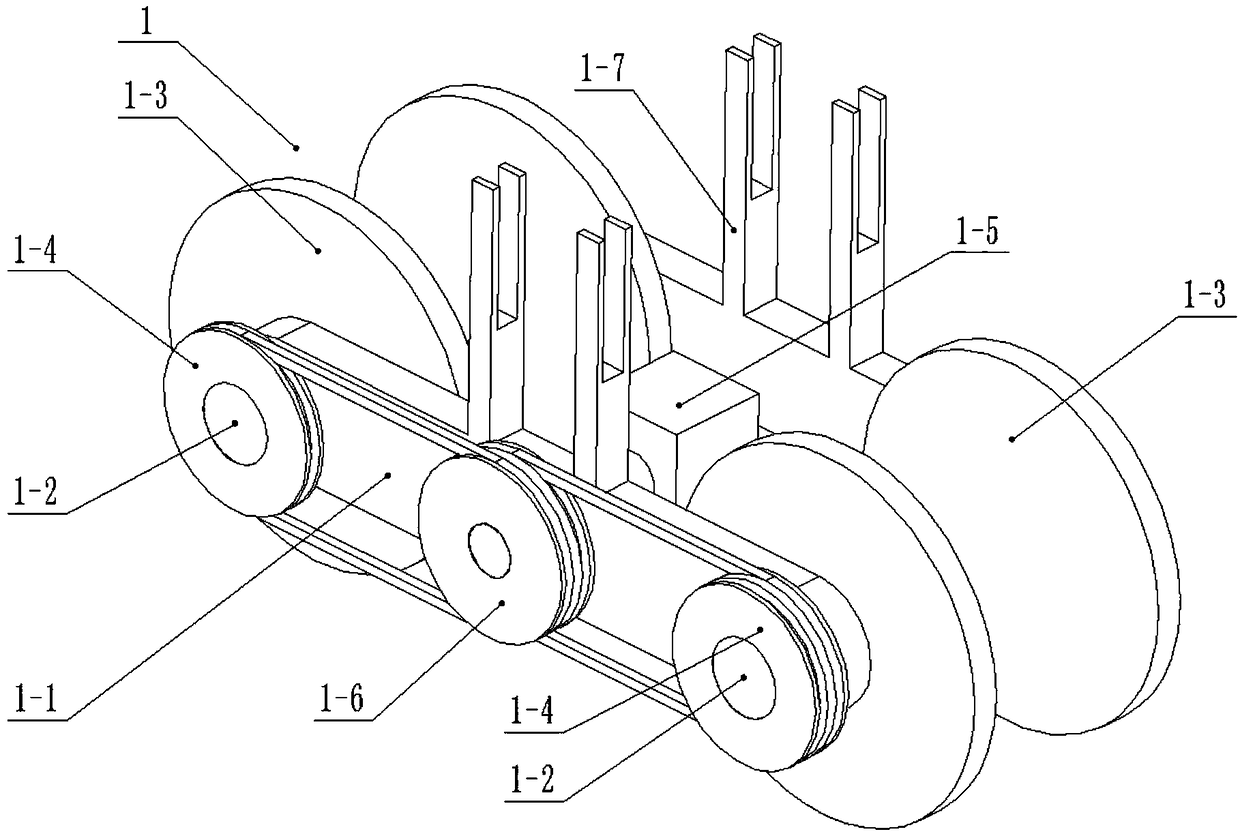

[0030] Combine below Figure 1-10Describe this embodiment, this embodiment will further explain the first embodiment, the cable propulsion device 1 includes a propulsion frame 1-1, two propulsion shafts 1-2, two lower crimping wheels 1-3, two Pulley Ⅰ 1-4, drive motor 1-5, pulley Ⅱ 1-6 and crimping carriage 1-7, the left and right ends of the propulsion frame 1-1 are respectively rotated and connected with a propulsion shaft 1-2, the propulsion shaft 1-2 is fixedly connected with a lower crimping wheel 1-3, the pulley I1-4 is fixedly connected to one end of the propulsion shaft 1-2, and the drive motor 1-5 is fixedly connected to the propulsion frame 1-1 , the pulley II 1-6 is fixedly connected to the transmission shaft of the drive motor 1-5, and the push frame 1-1 is fixedly connected with four crimping carriages 1-7, and the pulley II 1-6 They are respectively connected to the two belt pulleys I1-4 through belt transmission; the two lower crimping wheels 1-3 are driven to ...

specific Embodiment approach 3

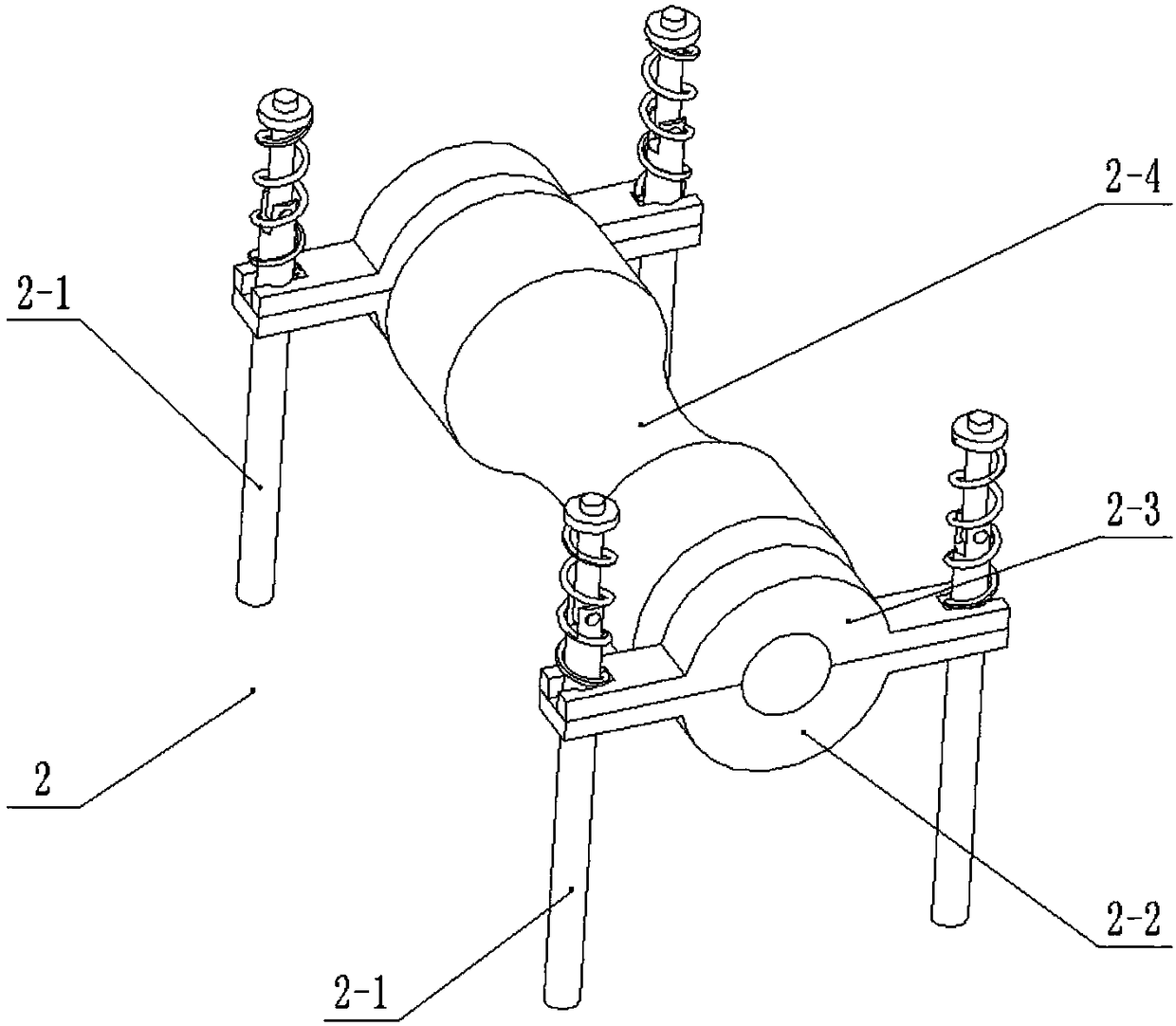

[0031] Combine below Figure 1-10 This embodiment will be described. This embodiment will further describe the second embodiment. The upper clamping device 2 includes a support rod 2-1, two lower shaft frames 2-2, two upper shaft frames 2-3 and an upper pressing Wire wheel 2-4, four support rods 2-1 are set, and the four support rods 2-1 are fixedly connected on the propulsion frame 1-1, and the four support rods 2-1 are connected with the four crimping wires respectively Sliding frame 1-7 is arranged relatively, two support rods 2-1 of the front end are slidingly connected with a lower shaft frame 2-2 and an upper shaft frame 2-3, and the two support rods 2-1 of the rear end are slidingly connected with A lower pedestal 2-2 and an upper pedestal 2-3, the lower pedestal 2-2 and the upper pedestal 2-3 are all slidably connected on the crimping carriage 1-7, the lower pedestal 2 Shaft holes are formed between -2 and the upper shaft frame 2-3, and the upper crimping wheel 2-4 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com