Automatic thin film replacing machine for plastic bag production

A refueling machine and film technology, applied in thin material processing, coiling, transportation and packaging, etc., can solve the problems of low production efficiency, complex process, high cost, etc., achieve high production efficiency, reduce staffing, operation convenient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be further described below in conjunction with accompanying drawing:

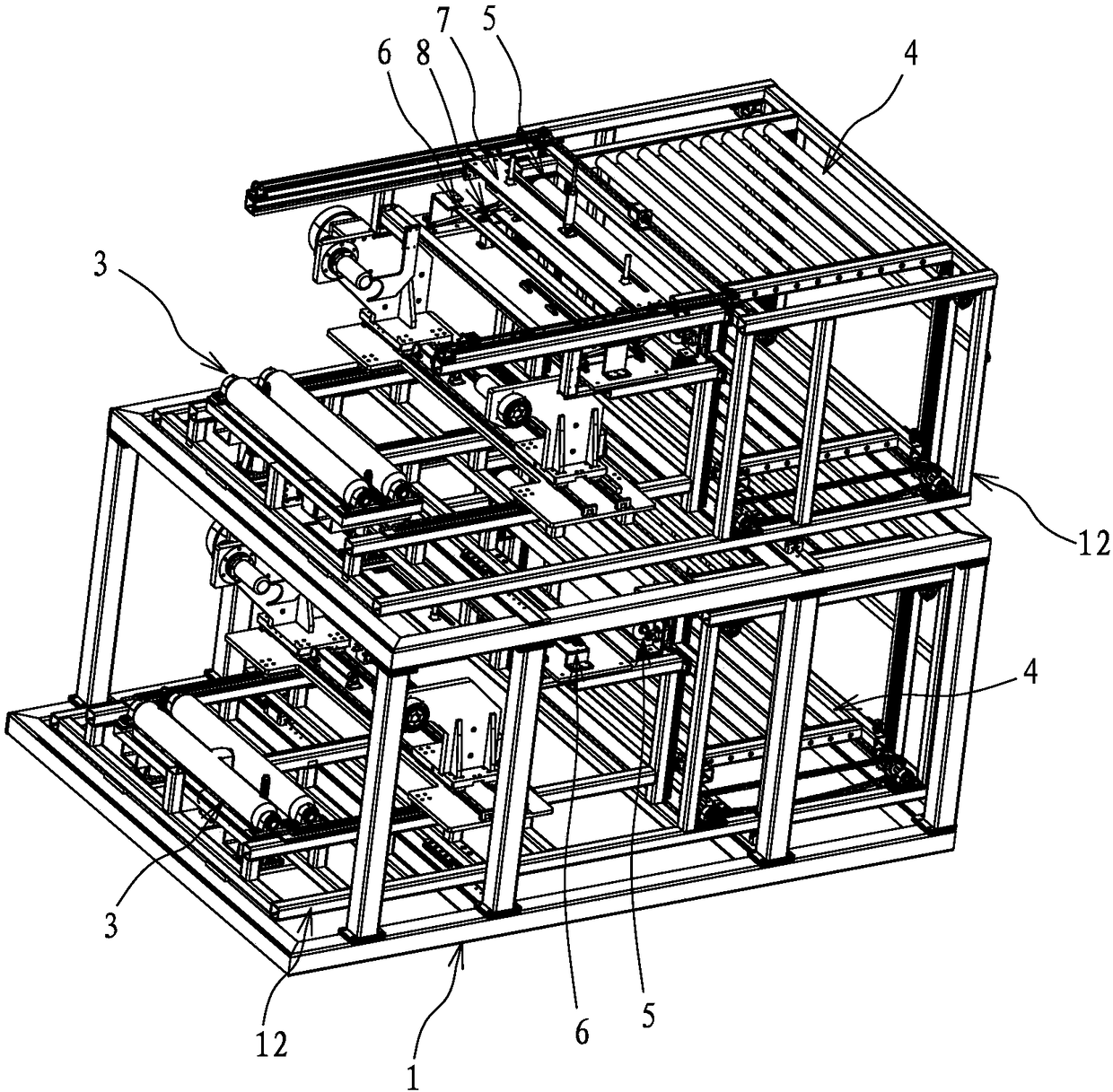

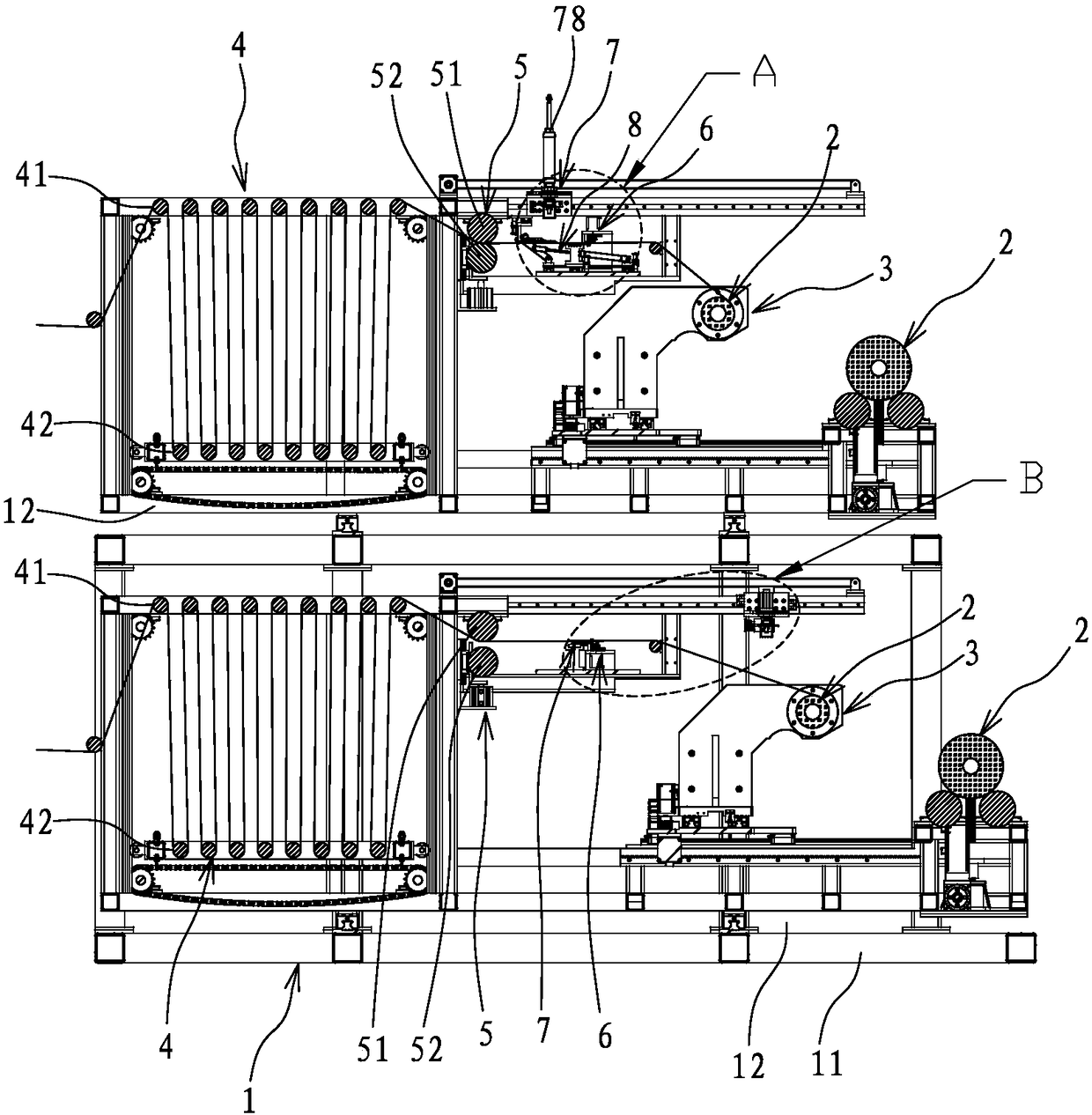

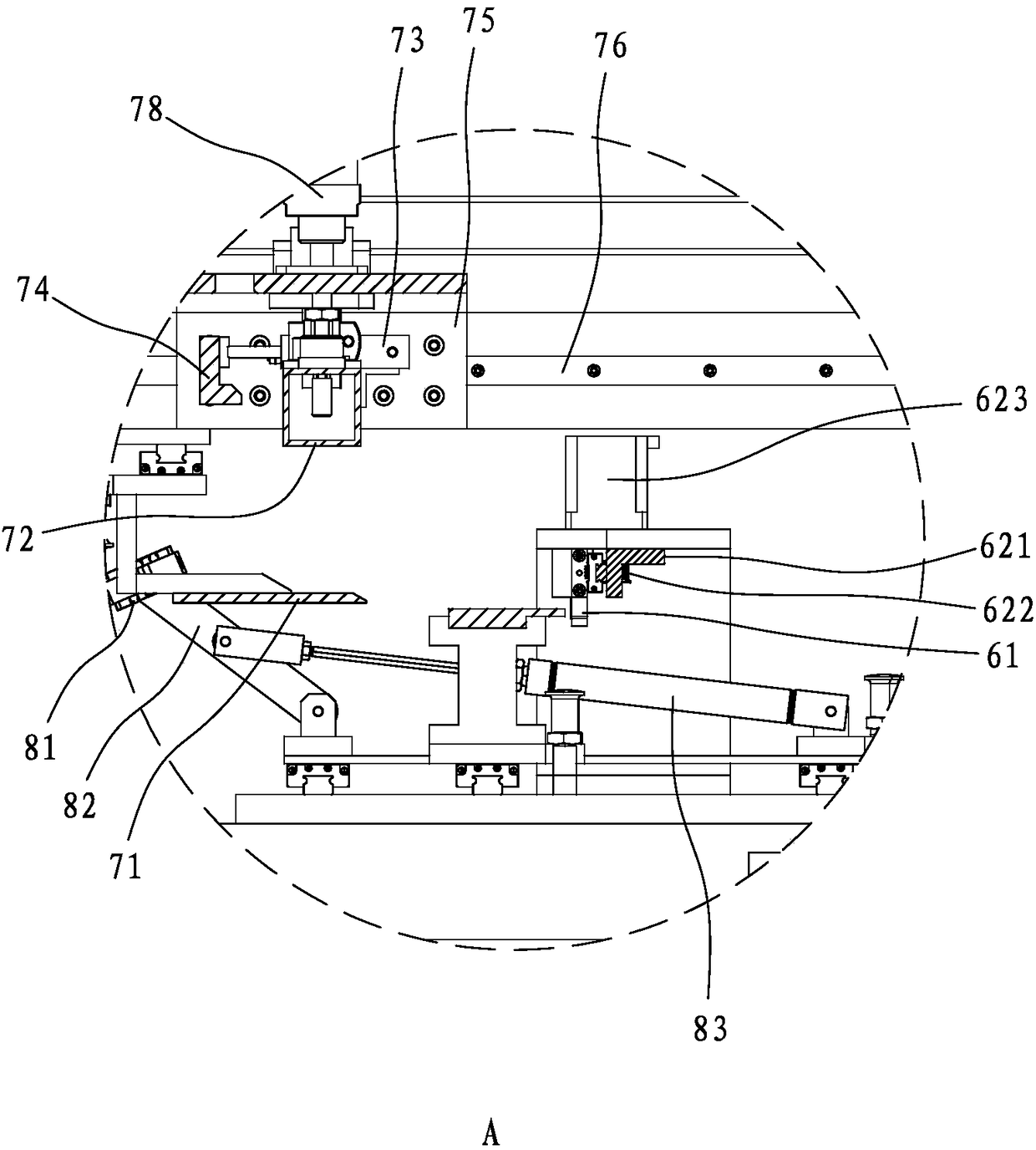

[0038] Such as Figure 1 to Figure 10A kind of film automatic refilling machine for the production of plastic bags shown includes a frame 1, which is provided with an upper and lower unwinding device 3 that can automatically erect the upper and lower film rolls 2 at the working position, and The upper and lower storage devices 4 for storing the upper and lower films released from the upper and lower unwinding devices 3 respectively, each of the unwinding devices 3 and the corresponding storage devices 4 is provided with a The fixing device 5 that clamps and fixes the film between the films to stop the film from advancing. When the fixing device 5 clamps the film tightly, the corresponding storage device 4 continues to transport the film stored therein for the production of plastic bags. , between each said fixing device 5 and the corresponding unwinding device 3, a cutting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com