System for processing coal gangue into cement dry powder raw material and processing method of system

A technology of coal gangue and raw materials, which is applied in the production of environmentally friendly cement main raw materials and its processing fields, can solve the problems of uneven particles, low crushing efficiency, and failure to meet the minimum requirements of carbon content, and achieve the goal of avoiding environmental pollution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

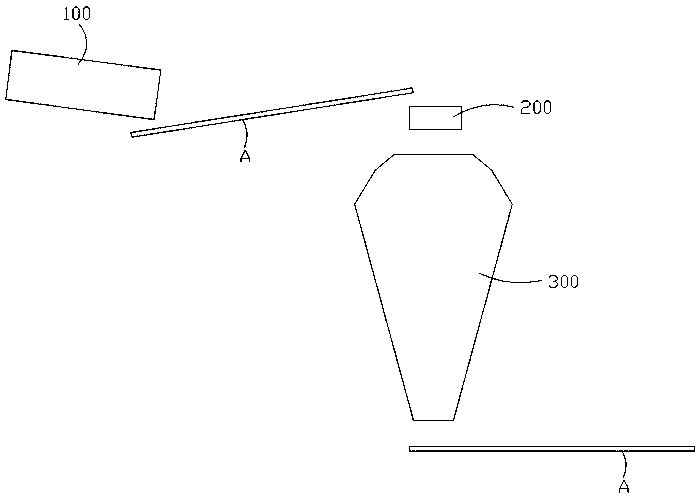

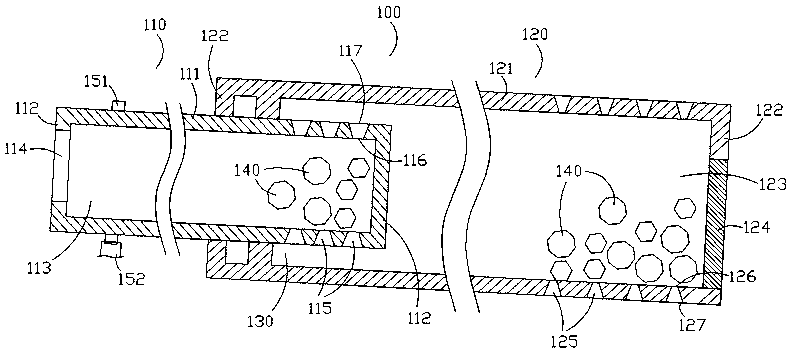

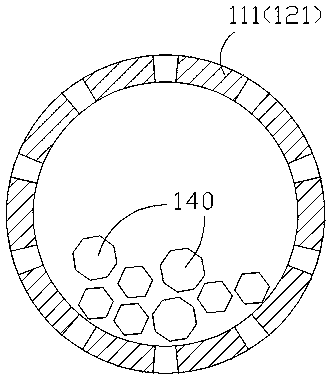

[0038] like Figures 1 to 6 As shown, a system for processing coal gangue into cement dry powder raw materials includes a coal gangue rolling crushing cylinder 100 , a coal gangue heating grinder 200 and a coal gangue powder combustion decarbonization furnace 300 .

[0039] The coal gangue raw material first enters the coal gangue rolling crushing cylinder 100 for rolling and crushing to obtain preliminary coal gangue powder, then, the preliminary coal gangue powder is sent into the coal gangue heating grinder 200 for grinding to obtain ground coal gangue powder, and finally, the grinding The coal gangue powder is sent into the coal gangue powder combustion decarbonization furnace 300 for combustion and decarbonization to obtain finished coal gangue powder, which is used as the basic raw material for making cement to produce cement.

[0040] The system of the present invention can sequentially crush, grind, and decarbonize coal gangue raw materials to make finished coal gangue...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com