A kind of repairing method of automobile carbon ceramic brake disc

A repair method and brake disc technology, which is applied to brake discs, mechanical equipment, gear transmission mechanisms, etc., can solve problems such as grooves or other damage to brake discs, affecting the braking performance of brake discs, and increased wear of brake pads. Achieve strong adhesion, excellent friction and wear performance, and avoid waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A method for repairing an automobile carbon-ceramic brake disc. The method includes five steps. The first step is to clean the brake disc to be repaired. The second step is to impregnate the carbon fiber cloth with resin. The third step is to carbonize the resin. finishing.

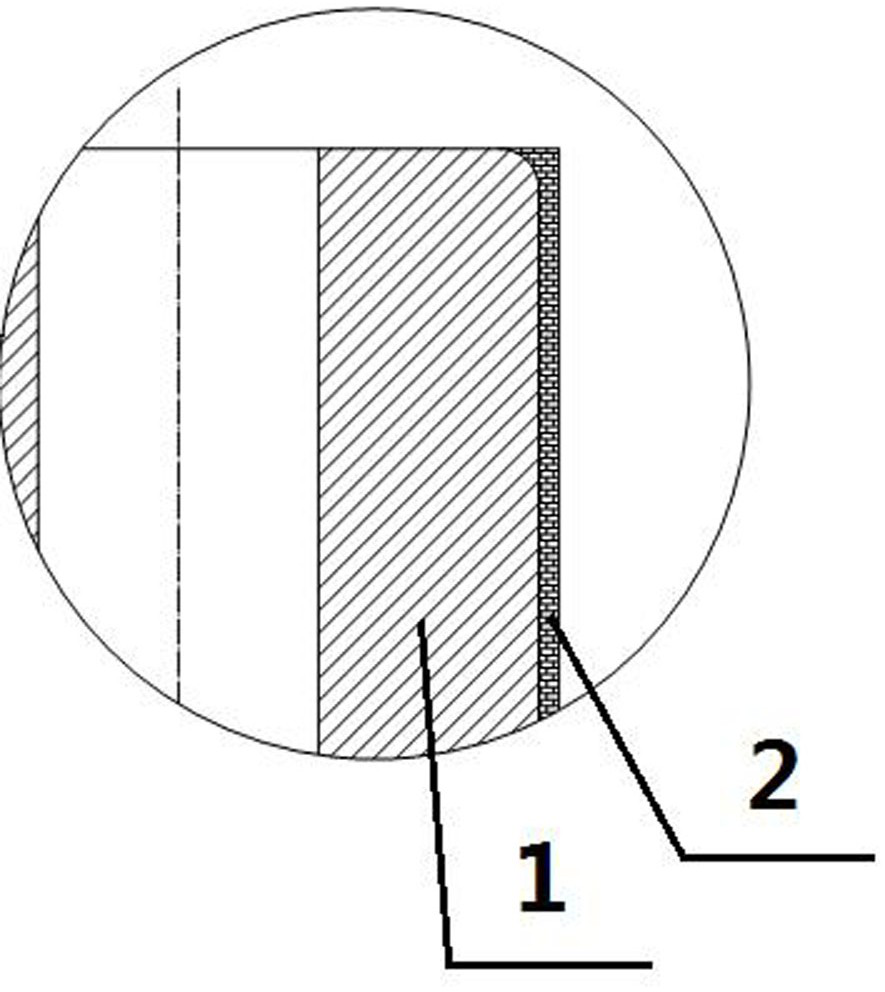

[0023] After the surface of the brake disc to be repaired is polished, it is cleaned and dried to prepare carbon fiber cloth, which is soaked in resin and adhered to the surface of the brake disc to carbonize the resin. / Tao Brake Disc.

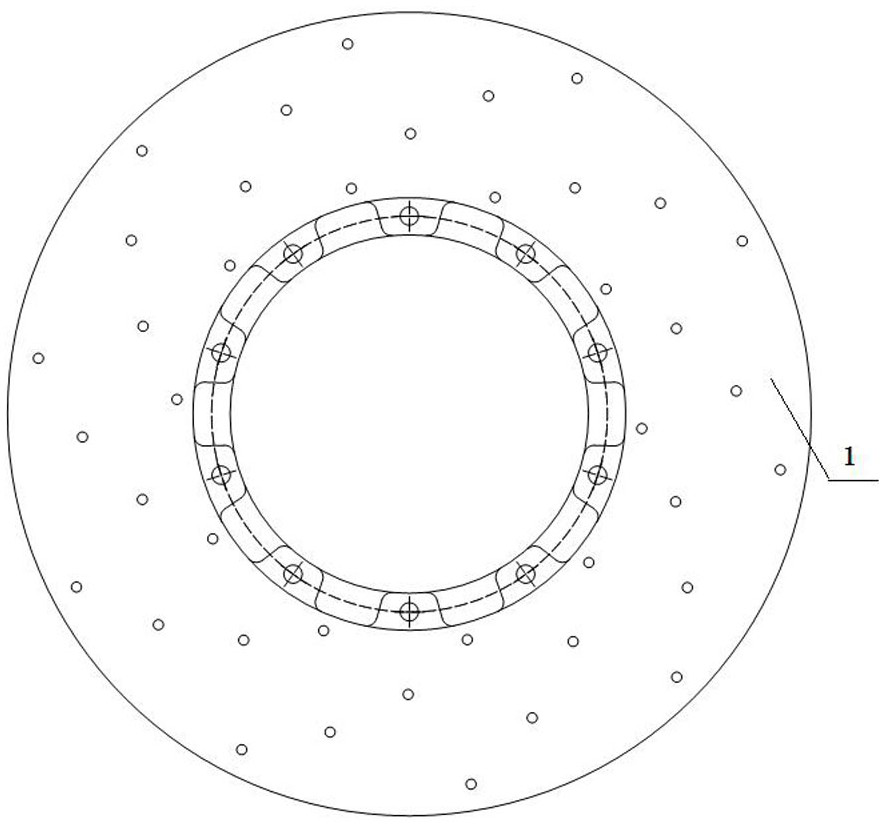

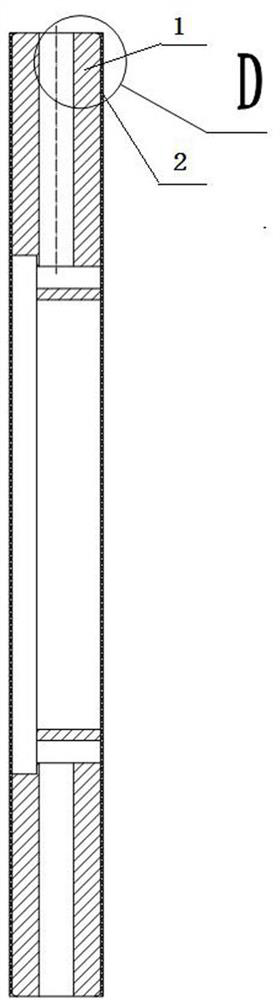

[0024] The outer side of the brake disc body is a repair layer.

Embodiment 2

[0026] A method for repairing an automobile carbon-ceramic brake disc described in Example 1, the first step of cleaning the brake disc to be repaired is to clean the sundries on the brake disc to be repaired with pure water, and then clean the surface Polish and smooth, then clean and dry; the second step of impregnating carbon fiber cloth with resin is to mix liquid thermosetting resin and curing agent, and obtain a uniformly dispersed resin mixture after stirring, fully soak the carbon cloth woven with carbon fiber in the resin; then adhere the impregnated carbon cloth to the surface of the cleaned brake disc; the third step of resin carbonization is to put the brake disc adhered to the carbon cloth into a vacuum graphitization furnace, and after the furnace is evacuated Fill the protective gas, maintain normal pressure in the furnace, and carry out graphitization treatment on the carbon cloth adhered to the resin at high temperature; in the fourth step of molten siliconizin...

Embodiment 3

[0028] A kind of repair method of automobile carbon ceramic brake disc described in embodiment 1 or 2, the thermosetting resin of described second step is phenolic resin or epoxy resin; The curing agent of described second step is p-toluene Sulphonic acid or phthalic anhydride; the carbon cloth in the second step is made of carbon fiber net tire transverse layup, and then longitudinal needle punching;

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com