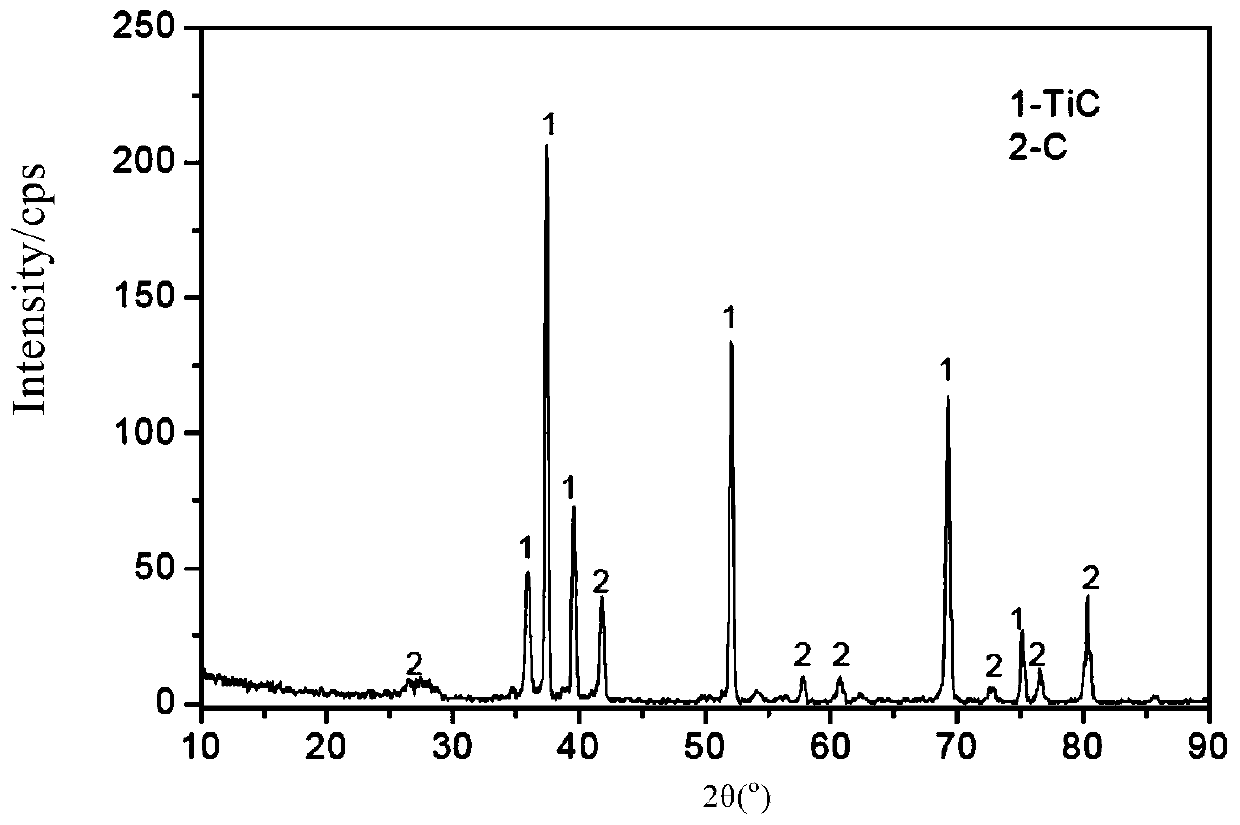

A method for preparing a hydrogen-free composite modified layer on a steel surface

A compound modification and steel technology, which is applied in the direction of metal material coating process, coating, solid diffusion coating, etc., can solve the problems of poor bonding performance, slow preparation speed, unfriendly environment, etc., and achieve high reliability and preparation The effect of low cost and good wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

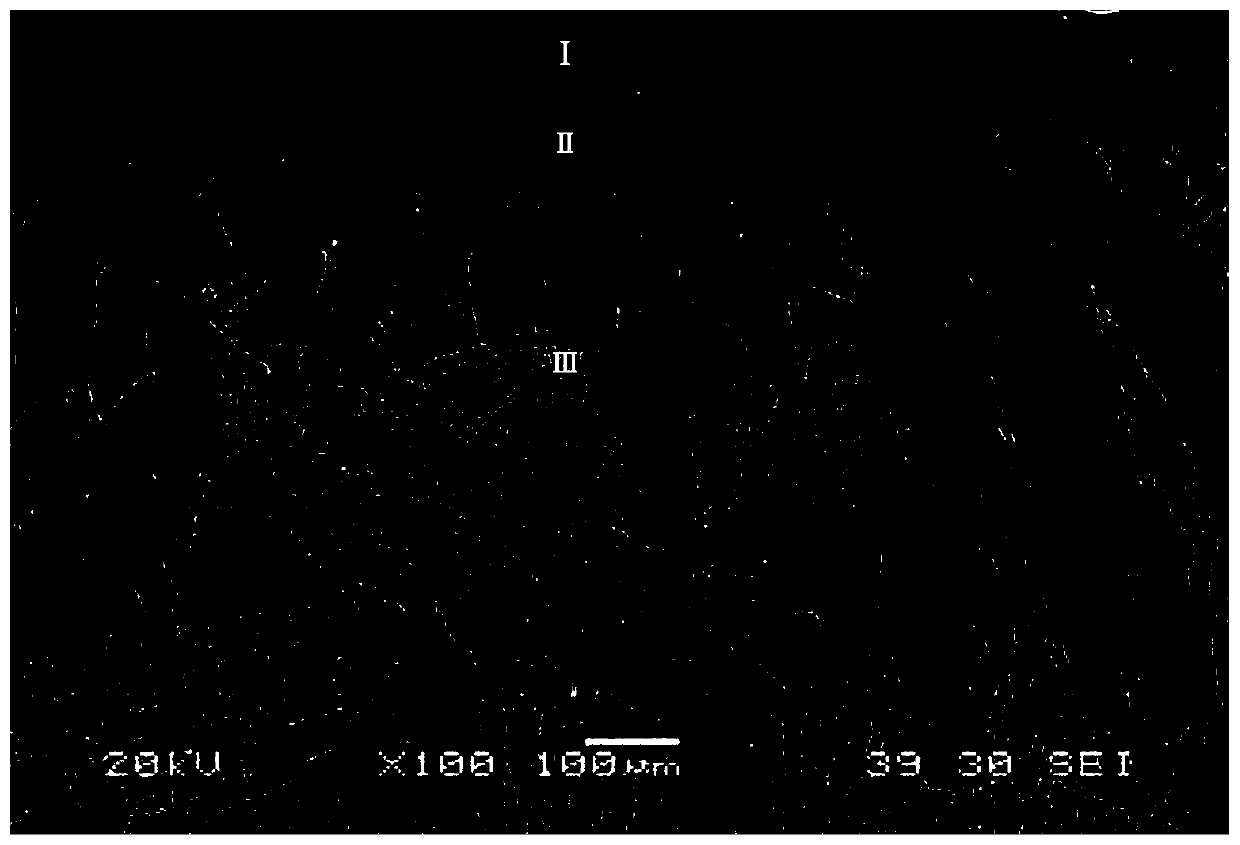

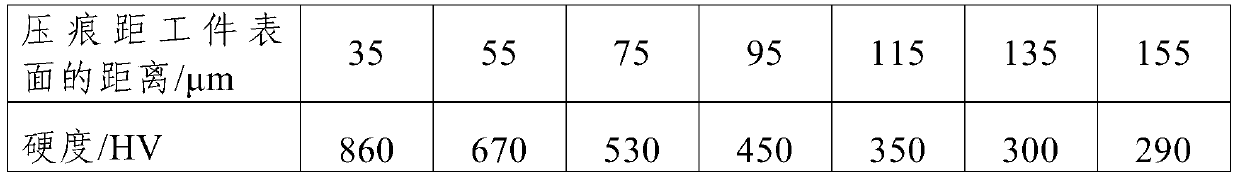

Embodiment 1

[0025] The preparation method of the present embodiment comprises the following steps:

[0026] Step 1. Pretreatment: Pickling, mechanical polishing, degreasing cleaning and drying treatment are carried out on the surface of the 316L stainless steel workpiece in sequence;

[0027] Step 2, titanium infiltration: the 316L stainless steel workpiece pretreated in step 1 is placed on the workpiece pole stage of the vacuum chamber of the double-layer glow plasma metal infiltration equipment, with the pure titanium plate as the source, the 316L stainless steel The workpiece is the working pole, the distance between the pure titanium plate and the 316L stainless steel workpiece is 10mm, and then pre-evacuated to 5×10 -2 Pa, heat the temperature of the 316L stainless steel workpiece to 400°C, keep it warm for 15 minutes, then pass argon gas into the furnace, adjust the pressure in the furnace to 20Pa, the loading voltage of the source electrode is 850V, and the loading voltage of the w...

Embodiment 2

[0036] The preparation method of the present embodiment comprises the following steps:

[0037] Step 1, pretreatment: pickling, mechanical polishing, degreasing cleaning and drying treatment are carried out sequentially on the surface of the 25# steel workpiece;

[0038] Step 2, titanium infiltration: place the pretreated 25# steel workpiece in step one on the workpiece pole stage of the vacuum chamber of the double-layer glow plasma metal infiltration equipment, and use the pure titanium plate as the source electrode, and the 25# The #steel workpiece is the working pole, and the distance between the pure titanium plate and the 25# steel workpiece is 12mm, and then pre-evacuated to 1×10 -2 Pa, heat the temperature of the 25# steel workpiece to 500°C, keep it warm for 15min, then pass argon into the furnace, adjust the pressure in the furnace to 25Pa, the loading voltage of the source electrode is 800V, and the loading voltage of the working electrode is 450V, Continue heating...

Embodiment 3

[0044] The preparation method of the present embodiment comprises the following steps:

[0045] Step 1, pretreatment: pickling, mechanical polishing, degreasing cleaning and drying treatment are carried out sequentially on the surface of the 45# steel workpiece;

[0046] Step 2, titanium infiltration: place the pretreated 45# steel workpiece in step one on the workpiece pole stage of the vacuum chamber of the double-layer glow plasma metal infiltration equipment, and use the TA1 titanium plate as the source, and the The 45# steel workpiece is the working pole, the distance between the TA1 titanium plate and the 45# steel workpiece is 20mm, and then pre-evacuated to 7×10 -2 Pa, heat the temperature of the 45# steel workpiece to 300°C, keep it warm for 20min, then feed argon gas into the furnace, adjust the pressure in the furnace to 50Pa, the loading voltage of the source electrode is 900V, and the loading voltage of the working electrode is 400V, Continue to heat the temperat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com