Apparent alumina concentration extraction method and equipment for aluminum electrolytic cell process control

A technology of process control and aluminum electrolytic cell, which is applied in the direction of electric digital data processing, special data processing application, instrument, etc., can solve the problem of not being able to analyze well the law of cell voltage signal frequency composition changing with time, false spectral peaks, and unclear Distinguishing the corresponding relationship between the tank voltage signal and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

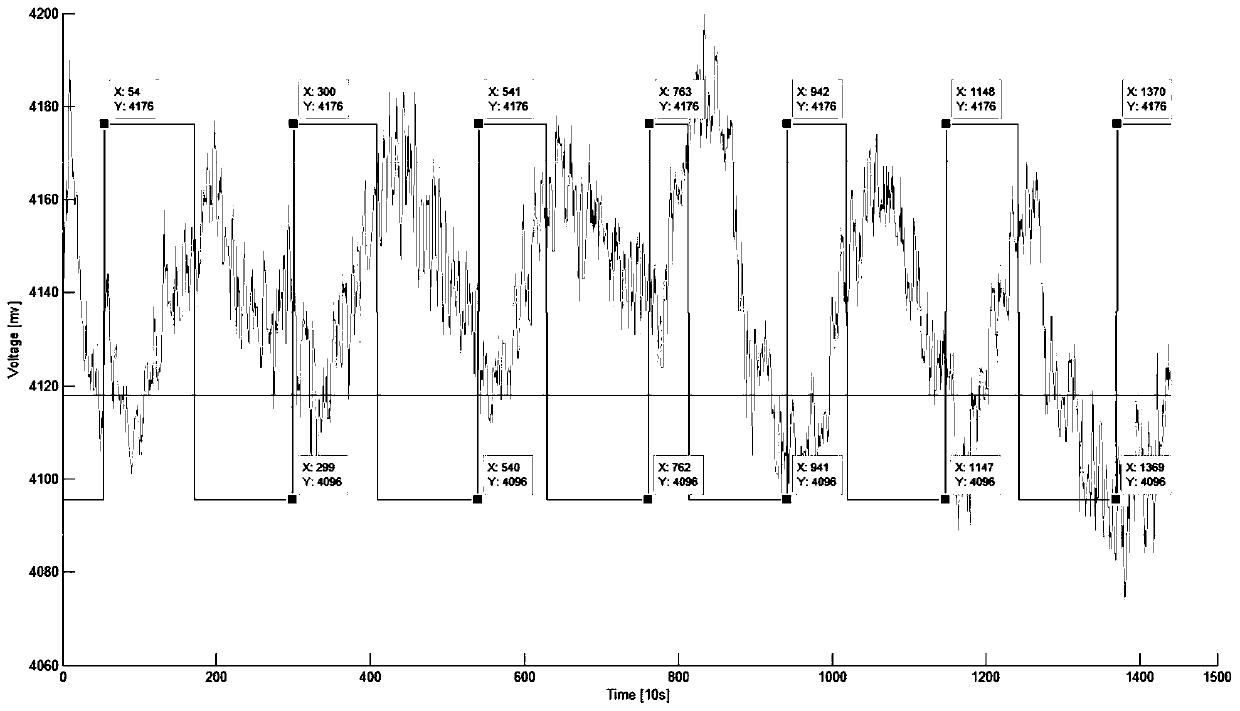

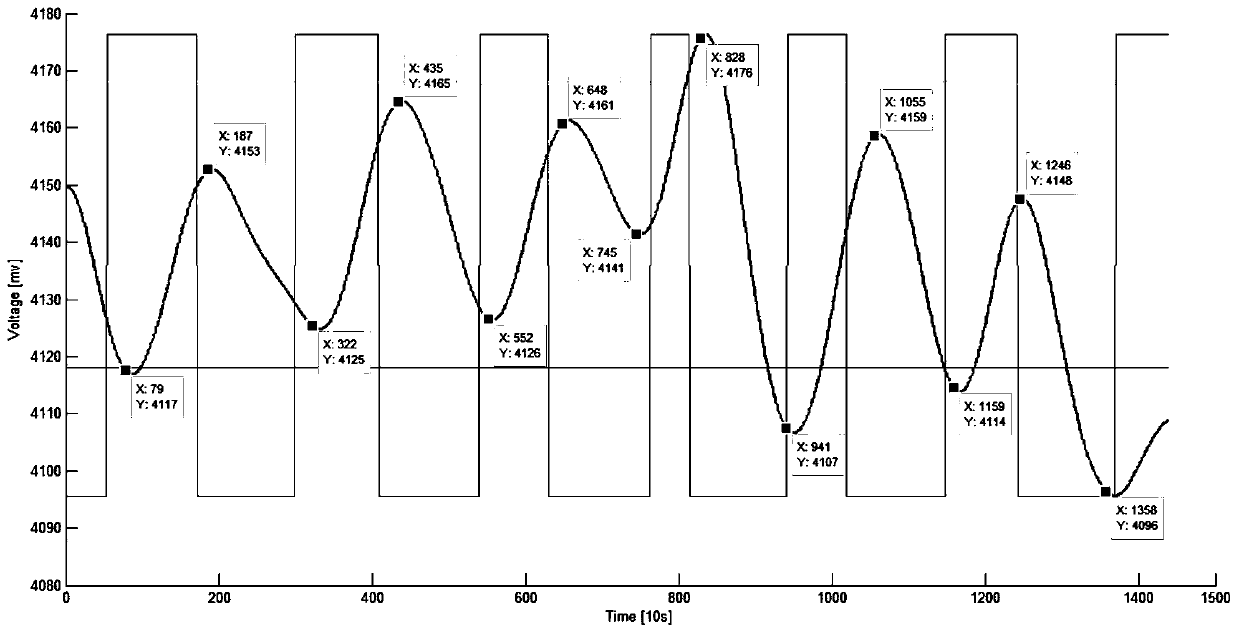

[0150] In the following, the sampling frequency of the 400kA aluminum electrolytic cell is f s =0.1Hz to normalize the tank voltage as an example, expand the description.

[0151] 1. Extraction of apparent alumina concentration

[0152] Take any section of normalized tank voltage data with obvious "under-rise and over-fall" law and record it as #1, as shown in Figure 2, there are 6 comprehensive cutting periods in Figure 2(a). The sampling frequency of this segment of data is 0.1 Hz, that is, Δt=10s, and the data length N=1440, that is, four hours of production data. When the aluminum electrolytic cell control machine collects this section of data, it does not have any routine operations such as aluminum discharge, pole change, and busbar lifting, nor does it have any special operations such as anode movement and edge processing, nor does it include special cell conditions such as anode effects.

[0153] In Figure 2, the wavy curve is the normalized tank pressure, the middle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com