Automatic production system of resist agent

A technology of automatic production and anti-dyeing agent, which is applied in the fields of dyeing, textiles and papermaking, and can solve the problems of low degree of automation, low production efficiency, and poor anti-dyeing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

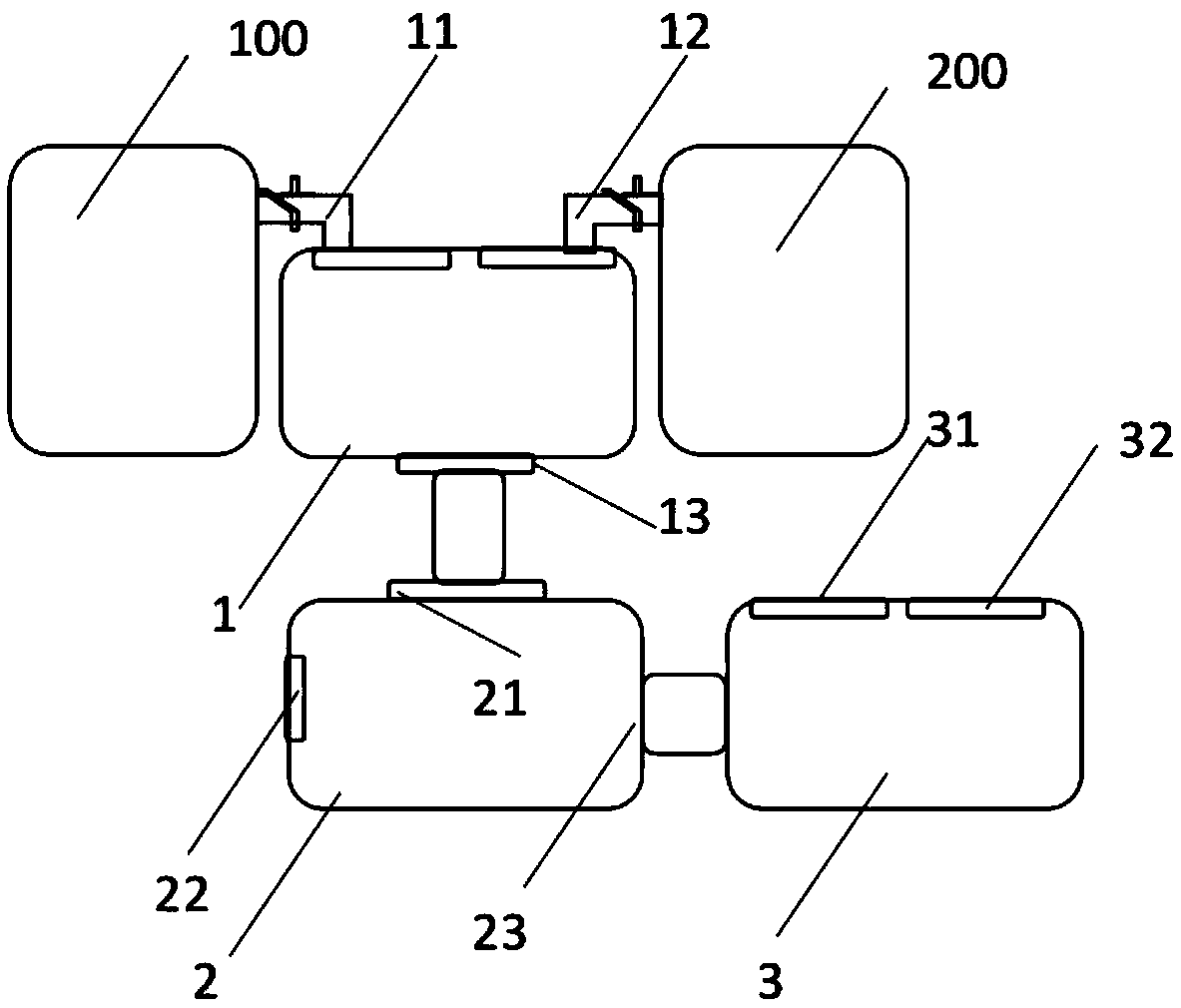

[0024] The embodiment of the present invention provides an automatic production system of anti-staining agent, such as figure 1 shown, including:

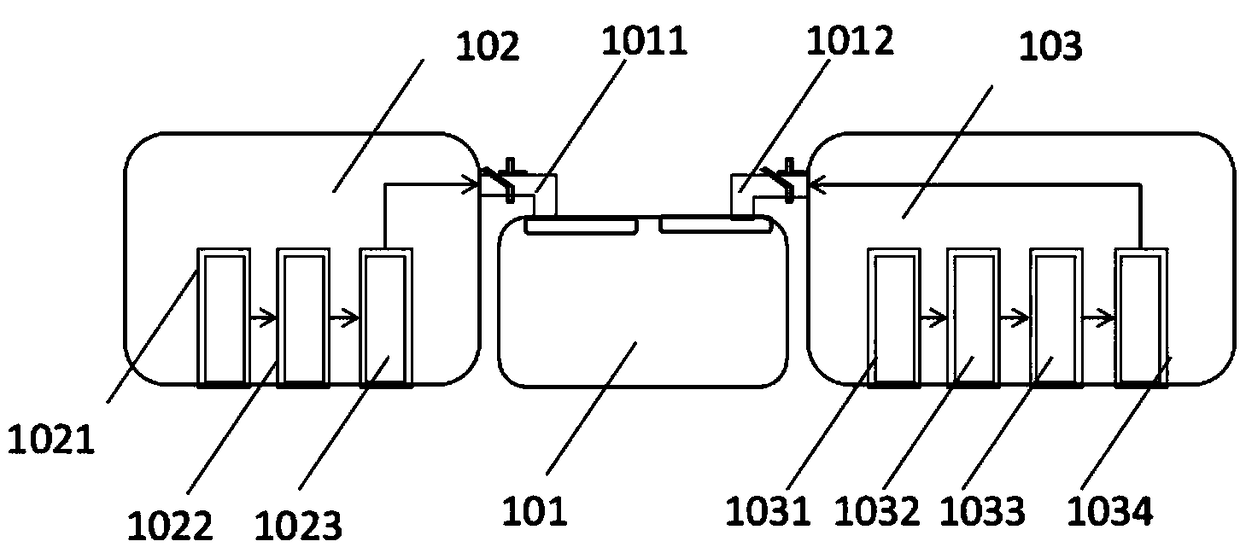

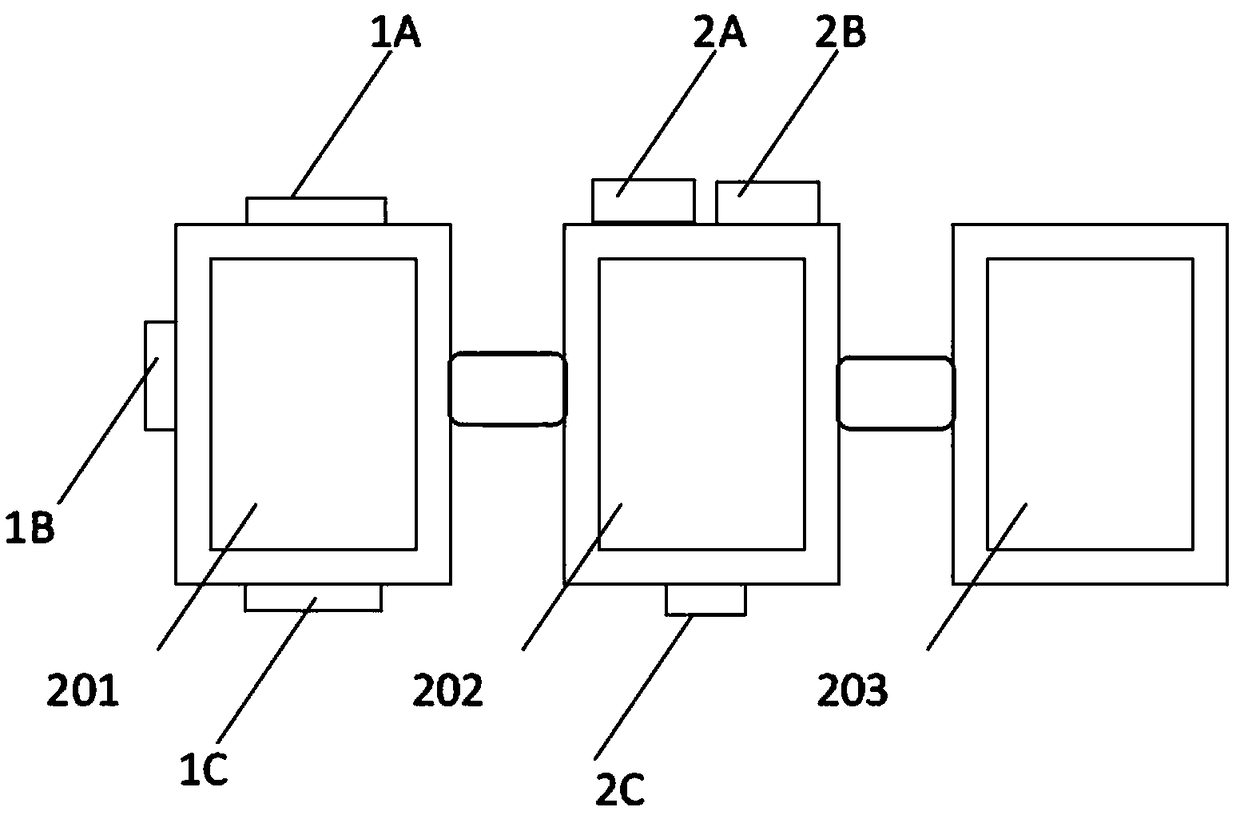

[0025] The first preparation pool 1, the second preparation pool 2 and the treatment pool 3 are connected in series in sequence, the first preparation pool 1 includes a first reagent injection port 11 for injecting an antifouling agent and a second reagent for injecting a penetrating agent The injection port 12, the first preparation pool 1 also includes a first discharge port 13, the first discharge port 13 communicates with the feed port 21 of the second preparation pool 2, and the second preparation pool 2 It also includes a third reagent injection port 22 , and the second reagent pool 2 also includes a second mate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com