Novel siphon type drainage device for cooling cylinder

A drainage device and straw-type technology, applied in textiles and papermaking, papermaking, papermaking, etc., can solve problems such as troublesome installation and maintenance work, and achieve the effects of easy maintenance, less water accumulation in the tank, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

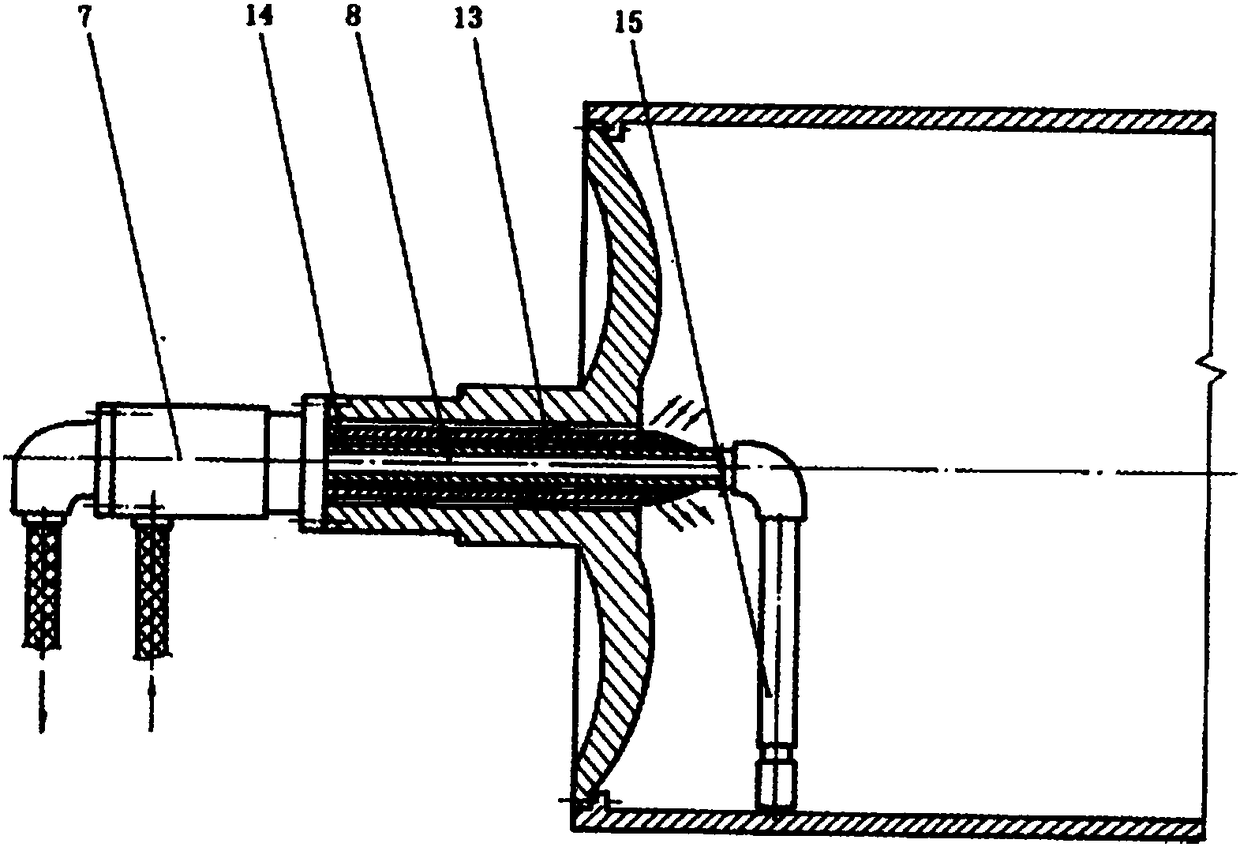

[0015] exist image 3 and Figure 4 In the specific embodiment shown, the drainage horizontal pipe (14) of the novel straw-type cold cylinder drainage device forms a coaxial casing structure inside the water inlet pipe (13) and the water inlet pipe (13), and one end of the water inlet pipe (13) is fixed Inside the rotary joint housing (10) and sealed by an O-ring (16), the other end is closed in the outer diameter of the drain horizontal pipe (14) inside the cold cylinder, and a water spray hole is drilled at the end to the inside of the cold cylinder Spray water, one end of the drainpipe horizontal pipe (14) is fixed inside the swivel joint swivel joint housing (10) and sealed by an O-ring (17), and the other end is connected to the drain vertical pipe (15) inside the cold cylinder. The support sleeve (9) of the rotary joint is fixed on the shaft head of the drying cylinder by a flange, and the external support sleeve supports the rotary joint shell (10) through two sets of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com