Gravity type fabricated ecological revetment structure and construction method thereof

A prefabricated, revetment technology, applied in the fields of botanical equipment and methods, piers, quay walls, etc., can solve the problems of inefficient energy saving, environmental protection, waste of building materials, long construction period, etc., to achieve less waste of resources, safe and stable structure, The effect of tight deadlines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

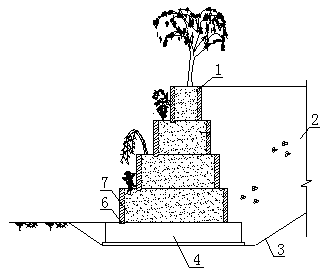

[0023] Such as figure 1 and figure 2 As shown, a gravity-type assembled ecological revetment structure includes a prefabricated box 1, backfill 2, a prefabricated floor 4 and planting soil material 7; The front and rear of the box 1 are in the shape of steps. The distance between the front steps of the upper and lower prefabricated boxes 1 must meet the space requirements for planting plants, and the distance between the back steps of the upper and lower prefabricated boxes 1 must ensure effective communication between the water and soil behind the wall and the prefabricated box. The need for connection; the lowest prefabricated box body 1 and the prefabricated bottom plate 4 are fixedly connected through concave-convex grooves, and two adjacent prefabricated box bodies 1 are fixedly connected through concave-convex grooves; the prefabricated box body 1 is provided with planting soil 7, Backfill 2 is arranged behind the prefabricated box body 1 . The upper and lower sides o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com