Post-molded foamed polyphenyl sandwiched composite heat insulation block making machine and implementation method

A block forming machine and composite thermal insulation technology are applied in the field of post-molding foamed polystyrene sandwich composite thermal insulation block forming machines, which can solve the problems of high production cost, poor quality, inability to achieve factory production and the like, and improve production. Benefit, reduce product cost, ensure the effect of quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

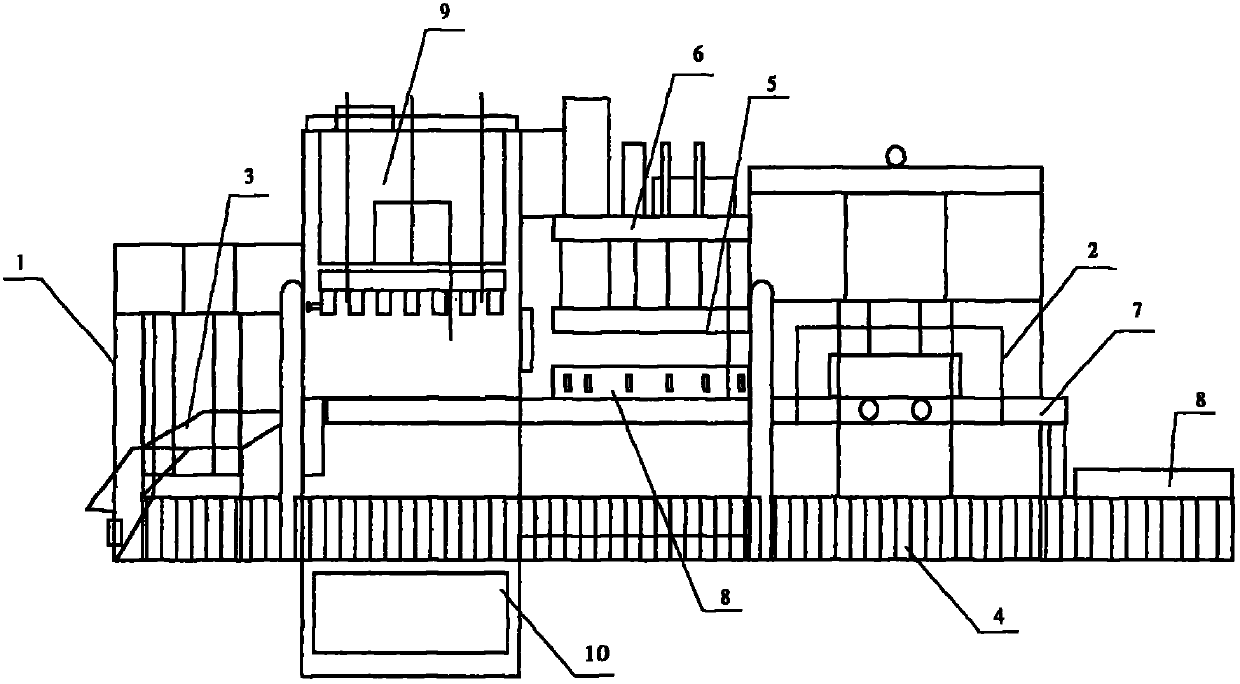

[0028] In order to further illustrate the present invention, further describe below in conjunction with accompanying drawing:

[0029] Such as figure 1 As shown, a post-molding foamed polystyrene sandwich composite thermal insulation block forming machine and its realization method of the present invention include a frame 1, one end of the frame 1 is provided with a mold raising machine 2, and the other end is provided with a mold lowering machine 3, A roller conveyor 4 is arranged below the frame 1, an upper mold 5 and a composite heat-insulating block molding device 6 are arranged directly above the frame 1, a chain conveyor belt 7 is arranged above the roller conveyor 4, and the roller conveyor 4 and At least one lower mold 8 is arranged on the chain conveyor belt 7 , and a gantry mechanical demoulding machine 9 and a cargo pallet 10 are arranged between the lower mold machine 3 and the upper mold 5 . There are four lower molds 8, and the lower molds 8 are recycled on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com